Master torque wrench calibration with our guide. Learn frequency, ISO standards, and DIY methods to ensure precise tool accuracy and safety.

An electric torque wrench is a rotary power tool used for tightening threaded fasteners, capable of outputting a set torque. It consists of a motor, torque control mechanism, torque output mechanism, and torque display mechanism. The accuracy of the electric torque wrench directly affects the quality of assembly; therefore, testing electric torque wrenches is a crucial step in ensuring product quality.

The Importance of Torque Wrench Calibration

Risks of neglecting torque wrench accuracy:

- Component failure: Insufficient torque can lead to loose fasteners and displacement due to vibration. Excessive torque can cause thread damage or complete bolt breakage.

- Safety hazards: In industries such as automotive, aerospace, and construction, a single failed bolt can have catastrophic consequences.

- Warranty invalidation: If equipment fails and you cannot prove the accuracy of your tools through traceable torque calibration, manufacturers will often refuse warranty claims.

Calibration ensures that the force applied by your tool precisely matches the specified force, providing repeatable accuracy. Whether you are manufacturing heavy machinery or assembling engines, continuous verification is the only way to guarantee that the work you do today will still be valid tomorrow.

Key Signs Your Torque Wrench Needs Calibration

Even top-tier tools suffer from torque wrench drift over time. Here is how to tell if your tool needs a trip to the lab.

- Inconsistent Readings: If the tool clicks too early on one bolt and too late on the next, your torque wrench accuracy is gone. For an electric torque wrench, watch out for digital readouts that fluctuate wildly or don’t return to zero.

- The “Drop” Factor: We have all dropped a tool on the shop floor. Unfortunately, a single hard impact on concrete can misalign the internal pivot block, requiring immediate torque wrench testing.

- Visible Wear and Rust: If I see corrosion on the ratchet head or a cracked handle, moisture has likely penetrated the internal spring mechanism. Rust increases friction, meaning the wrench clicks before it actually hits the target torque.

- Overloading or Improper Use: Never use your torque wrench as a breaker bar to loosen stuck fasteners. Pushing the tool beyond its maximum capacity stretches the spring and permanently alters the calibration.

- Extreme Environments: Leaving tools in a freezing truck or a hot dashboard affects the lubricants and metal expansion. If your gear faces these extremes, you need more frequent checks.

- High Usage Cycles: The general rule is to calibrate every 5,000 cycles. If you are using this tool daily in a production environment, you are likely hitting that limit faster than you think.

Pro Tip: If you suspect your tool is off, don’t guess. Comparing it against a torque sensor or another calibrated wrench is the only way to be sure.

How Often Should You Calibrate a Torque Wrench?

In the industry, we live by a pretty standard rule regarding torque wrench calibration frequency: you need to service your tool every 12 months or every 5,000 cycles, whichever comes first. This aligns with the widely accepted ISO 6789 standard.

However, that one-year mark is just a baseline. Real-world conditions often demand tighter intervals.

Torque wrench drift is inevitable, but certain factors speed up the process. If your operations fall into these categories, you should cut that calibration interval in half (every 6 months):

- Heavy Daily Use: If you are on an assembly line cranking bolts all day, you will hit 5,000 cycles in a few months.

- Harsh Environments: Extreme heat, freezing cold, or high humidity affects the internal lubricants and metal components.

- Critical Applications: For high-stakes jobs in aerospace or structural steel, we often test accuracy before every shift.

- Mishandling: Dropping the wrench or using it as a breaker bar instantly invalidates previous calibration.

Torque Wrench Calibration Standards

When we talk about professional reliability, we are talking about adhering to the ISO 6789 standard. This isn’t just red tape; it is the global benchmark for torque wrench calibration. Under ISO 6789:2017, the tool must be tested at 20%, 60%, and 100% of its maximum capacity. This multi-point testing ensures your wrench maintains accuracy across its entire usable range, not just at the top end.

DIY Torque Wrench Calibration

For the Saturday mechanic or general maintenance, a DIY check is a fantastic way to spot torque wrench drift before it strips a bolt. It serves as a “sanity check.”

The physics here are simple: Torque equals Force times Distance. By hanging a known weight at a specific distance from the square drive, we generate a precise amount of torque to see if the wrench clicks (or reads correctly) at that setting.

- Secure the wrench horizontally (e.g., clamp the drive end to a workbench).

- Attach a known weight to the handle at a specific distance from the drive (e.g., 1 foot).

- Calculate the expected torque (Torque = Force × Distance; Force = Mass × Gravity).

- If the wrench clicks when the calculated torque is reached, the torque is accurate; otherwise, professional adjustment is needed.

Note: DIY methods cannot fix calibration problems—they can only identify them.

Professional Torque Wrench Calibration Process

Proper torque wrench calibration follows a rigorous, standardized workflow to ensure absolute precision.

Here is the step-by-step procedure we follow in the lab:

- Confirm Calibration Basis

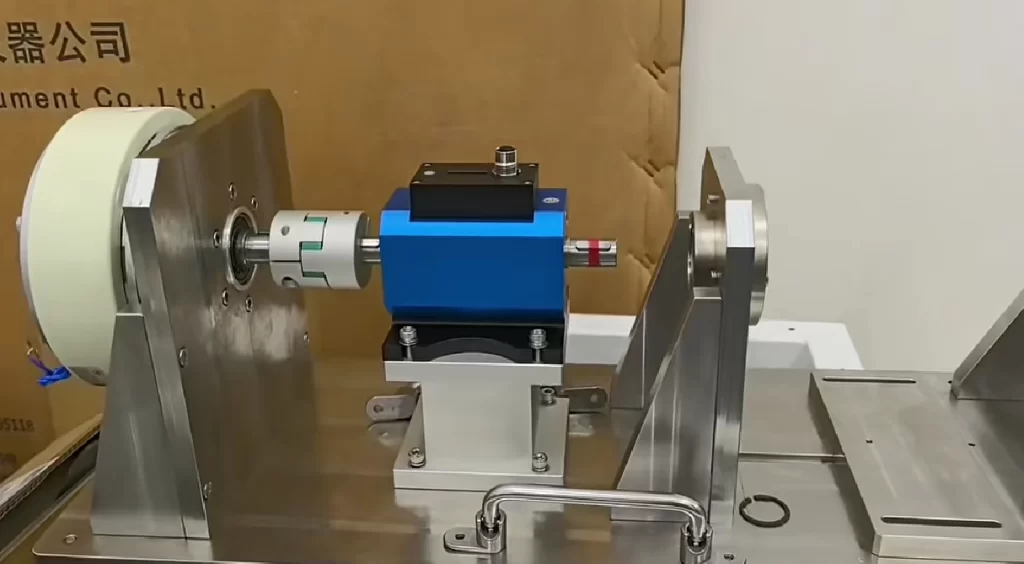

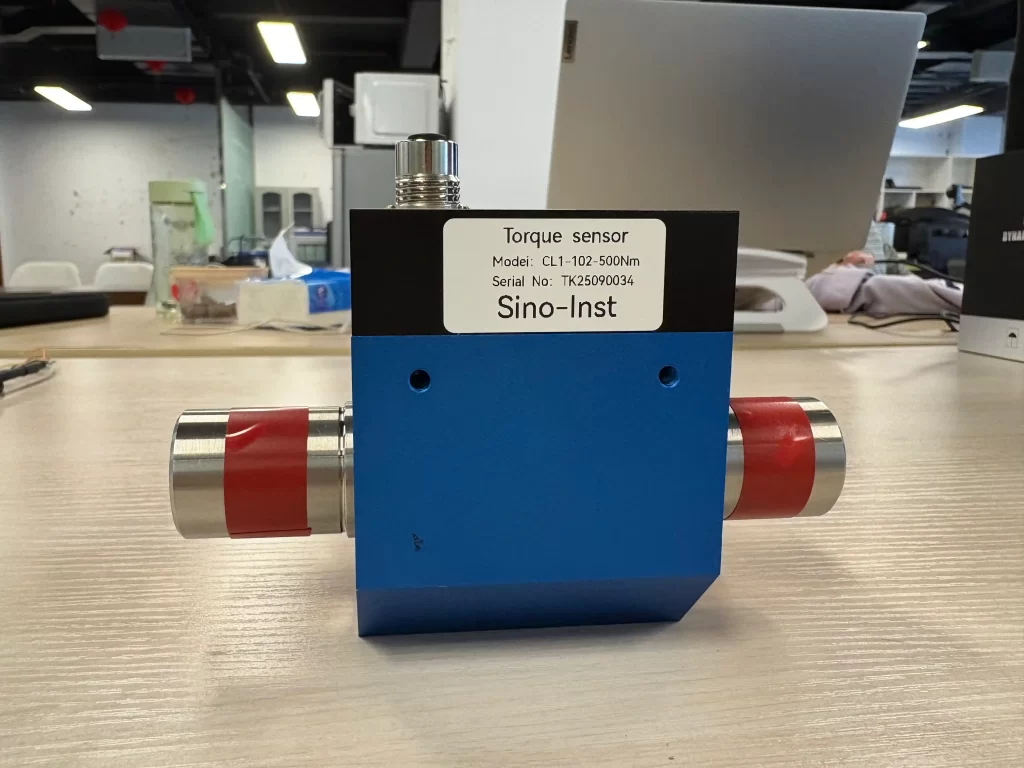

- Dynamic Torque Measurement Instrument

Torque measurement uses a rotary torque sensor, and the display instrument can show the peak value, with a sampling frequency of no less than 500 Hz. The expanded uncertainty of the torque meter’s reading should not exceed 1/3 of the expanded uncertainty of the torque wrench being calibrated.

- Calibration Point Selection

Calibration points need to be selected for the torque wrench, usually 20%, 60%, and 100%, as well as any torque values specified by the user.

- Pre-loading Torque

Connect the torque sensor, threaded torque connection simulator, and torque wrench in sequence. From bottom to top, the order is torque sensor, threaded torque connection simulator, and torque wrench. Ensure their coaxial alignment as much as possible during connection.

Zero the torque meter (torque sensor, display, etc.) and apply torque to the maximum value of the calibration point. Complete this pre-loading torque process 3 times.

- Applying Torque

When starting the formal measurement, for horizontally held electric wrenches, ensure the wrench’s lever arm is horizontal; for vertically held electric wrenches, ensure the lever arm is vertical. Press the wrench’s rotation button, steadily apply torque, and record the peak value displayed on the instrument.

Repeat the measurement 10 times for each calibration point, using the average of the 10 measurements as the result. Replace the simulator with different torque rates and repeat the above measurement steps.

- Calculating Error

Calculate the relative error, repeatability, and interpolation error of the high and low torque rate readings using the formula.

FAQ

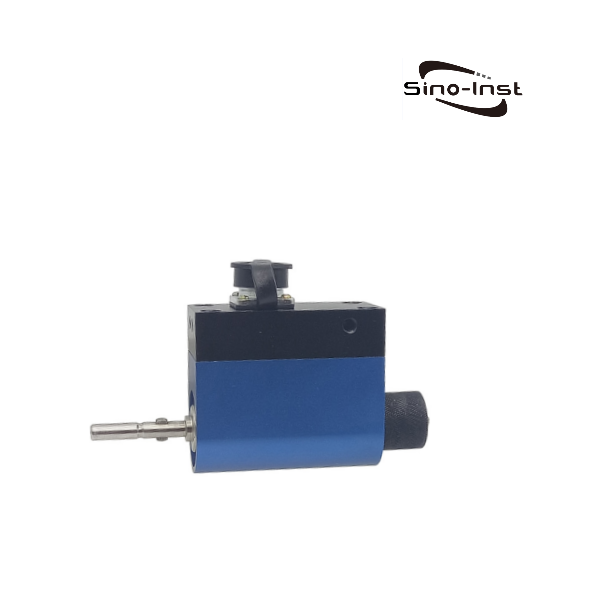

Choosing the Right Torque Wrench Calibration Tools

If you are serious about torque wrench calibration, you need the right hardware. You can’t just guess; you need a setup that delivers repeatable, traceable results. A standard professional rig usually includes a digital torque tester, high-precision torque transducers, and a sturdy calibration bench to hold everything steady.

The torque transducer is the heart of the system—it converts the mechanical torque force into a readable electrical signal. If that sensor isn’t accurate, your entire calibration process is flawed.

Technical Suport

Strain Gauge Torque Sensors & Transducers – Technology and Selection Guide

What is a Reaction Torque Sensor? Product Lists and Guide

Static Torque vs Dynamic Torque: A Practical Guide to Selecting the Right Sensor in 2026

Motor Torque Measurement – Static and Dynamic Sensors

What Is a Torque Sensor? and Types

Shaft Torque Sensors – Product List and Work Guide

What is Contactless Torque Sensor and Technology?

Industrial Applications of Torque Sensors

What Is a Rotary Torque Sensor?

How to Measure Torque?

At Sino-Inst, we specialize in high-precision torque sensors and torque wrench calibration tools designed for industrial reliability.

Whether you are running a dedicated calibration lab or checking tools on a manufacturing floor, our equipment gives you the data you need to maintain accuracy.

Feel free to contact us for customized torque measurement solutions.

-1.jpg)