By exploring the types and principles of strain gauge torque sensors, analyzing selection guides and calibration-related issues, we hope to help you choose the high-precision rotary and reaction torque measurement solutions that meet your needs.

How Strain Gauge Torque Sensors Work?

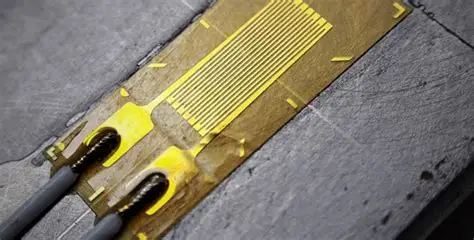

The core principle of the Strain gauge torque sensor is simple: we are converting mechanical shear stress (the twist) into a change in electrical resistance.

When a metal shaft is under torque, it deforms slightly—imperceptibly to the human eye, but easily detected by our sensors. We bond a tiny strain gauge to the shaft. As the shaft twists, the gauge stretches or compresses, changing its resistance.

Optimal 45° Orientation for Sensitivity

We don’t just slap these gauges on the metal randomly. For a rotary torque sensor to work effectively, the gauges are mounted at a specific 45° angle relative to the shaft’s axis.

Why 45 degrees? That is exactly where the tensile and compressive forces are at their peak during rotation. By aligning them this way, we capture the maximum amount of “twist” data possible.

Wheatstone Bridge Torque Measurement

A single gauge isn’t enough for industrial accuracy. A single gauge can get confused by temperature changes—if the shaft gets hot and expands, a single gauge might think that’s torque.

To solve this, we arrange four gauges in a Wheatstone bridge torque measurement circuit (a full-bridge configuration). This setup is the industry standard for two reasons:

- Temperature Compensation: It cancels out resistance changes caused by heat, so you only measure the torque.

- Signal Amplification: It boosts the electrical output, making it easier for your DAQ system to read.

Types of Strain Gauge Torque Sensors

We generally categorize strain gauge torque sensors into two main families: reaction (static) and rotary (dynamic). Therefore, the key consideration when choosing one is whether the object is rotating or not.

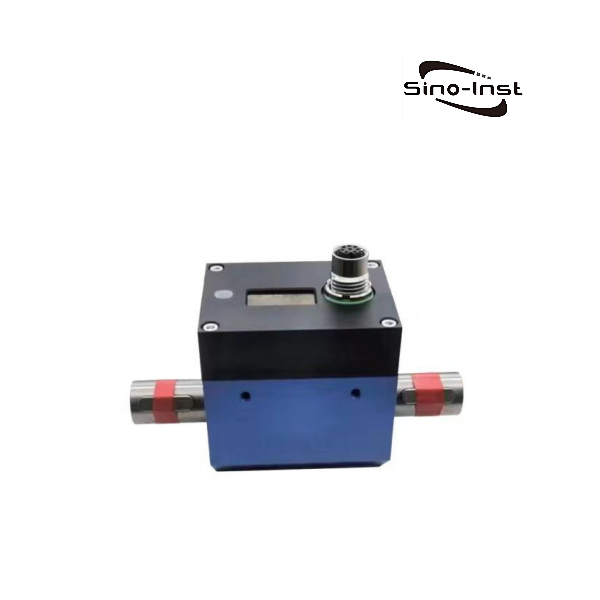

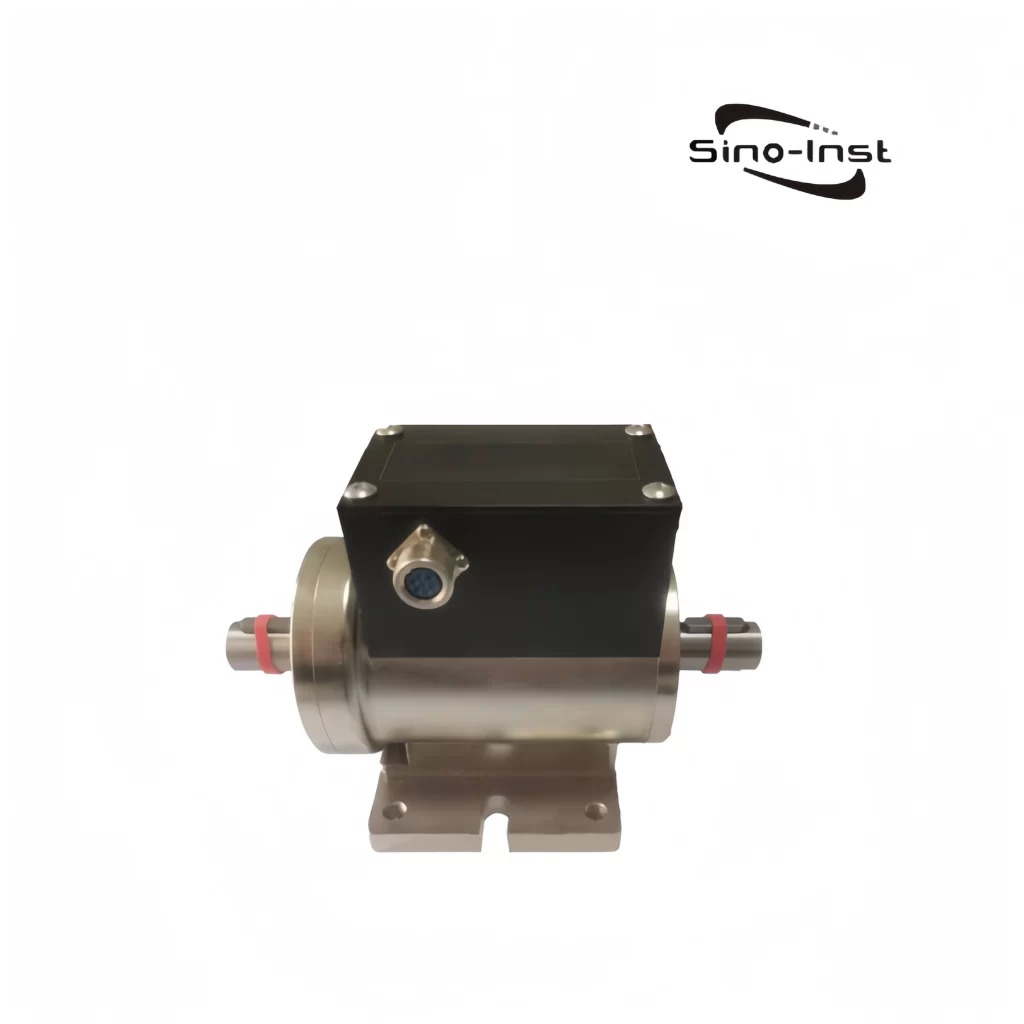

Reaction (Static) Torque Sensors

If you need to measure torque on a shaft that isn’t spinning—or rotates less than 360 degrees—a reaction torque transducer is your go-to solution. Since there are no rotating parts, we don’t have to worry about complex signal transmission. This makes the design robust and cost-effective.

The Advantage: Because we eliminate bearings and slip rings, you get simpler wiring and significantly higher accuracy in non-rotating applications.

These static torque sensors are built for high-precision stability. We typically deploy them for:

- Calibration: acting as a master reference for torque wrenches.

- Fastener Testing: measuring the break-away torque of bolts.

- Actuator Monitoring: checking process torque on non-rotating machinery.

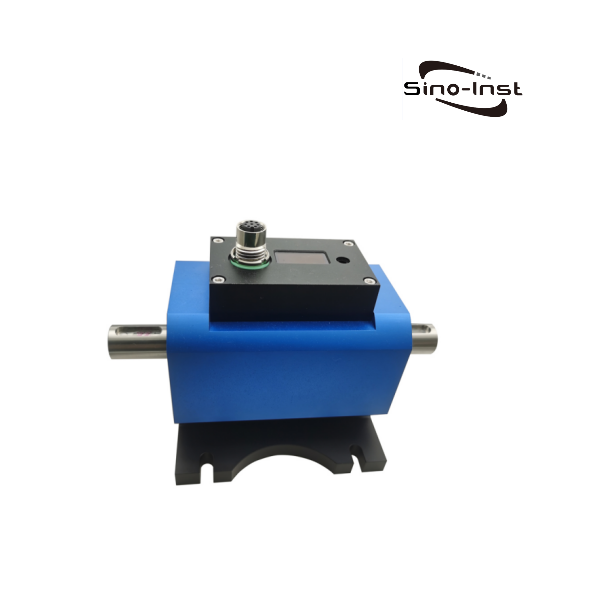

Rotary (Dynamic) Torque Sensors

Measuring torque on a spinning shaft adds a layer of complexity. An inline rotary torque sensor must capture the electrical signal from the strain gauge (which is spinning) and send it to the stationary housing.

For dynamic torque measurement, getting that signal off the shaft is the biggest engineering challenge. Older designs used slip ring torque sensor technology, where physical brushes touched the shaft. While affordable, they suffer from wear and electrical noise.

Today, we focus on non-contact methods for high-speed torque sensing.

Comparison of Signal Transmission Methods:

| Method | How It Works | Pros | Cons |

| Slip Rings | Physical brushes contact rings on the shaft. | Economical; Compact size. | Brushes wear out; RPM limits; Electrical noise. |

| Rotary Transformer | Inductive coupling transfers power and signal. | Contactless; Low maintenance. | Susceptible to electromagnetic interference (EMI). |

| Non-Contact Telemetry | Digital transmission (like radio). | Noise-free; High RPM; No wear; High accuracy. | Higher initial cost. |

For most modern industrial applications, non-contact torque telemetry is the gold standard. It allows for wireless torque measurement without the maintenance headaches of slip rings, ensuring your data is clean and your sensor lasts longer.

If you aren’t sure if a static or rotary unit fits your setup, contact us at Sino-Inst. We can walk you through the specifics of your drive line.

Key Technical Specs for Strain Gauge Torque Sensors

To get reliable data, you need to match the strain gauge torque sensor capabilities to your specific mechanical reality. Here is the breakdown of the critical specifications we look at first.

This is step one. You never want to run a sensor exactly at its limit. We generally recommend selecting a range that is 20% to 30% higher than your application’s maximum operating torque.

You also need to verify the Safe Overload capacity. Most quality sensors offer 150% of Full Scale (FS). This buffer is crucial for protecting the gauge during startup spikes or accidental jams

Torque sensor accuracy isn’t just a single number; it is a combination of several factors. For precision testing, you want a “Combined Error” (Linearity + Hysteresis + Repeatability) of ±0.1% ~ ±0.25% F.S.

- Non-Linearity: How much the signal deviates from a perfect straight line.

- Hysteresis: The difference in reading when you load up versus when you unload.

- Repeatability: The ability to give the same reading for the same torque, time after time.

For dynamic torque measurement, verify the Maximum Rotational Speed. Running a 5,000 RPM shaft on a sensor rated for 3,000 RPM will destroy the bearings or overheat the slip rings.

You also need to choose the right output for your DAQ or PLC.

| Signal Type | Standard Specs | Best Use Case |

| Analog Voltage | 0-5V, 0-10V, ±10V | Fast response, general lab testing. |

| Analog Current | 4-20mA | Industrial environments with electrical noise or long cable runs. |

| Digital | RS485 (Modbus), CAN bus | Non-contact torque telemetry setups requiring high data integrity. |

| Frequency | 5kHz – 15kHz | High-speed RPM and torque integration. |

If you are testing in a hot engine bay or a freezing outdoor rig, standard sensors will drift. Look for temperature compensation ranges (usually -10°C to +60°C). For dirty US industrial environments, ensure the housing has an IP65 or IP67 rating to block out dust and moisture.

Some of our advanced units also feature integrated speed measurement, allowing you to calculate horsepower (Power = Torque x RPM) directly from a single device.

Advantages and Limitations of Strain Gauge Technology

When I talk to customers about torque measurement, I usually steer them toward strain gauge torque sensors first. Why? Because for 90% of industrial applications in the US, this technology offers the best balance of performance, price, and reliability. It is the gold standard for a reason.

The core strength of a bonded foil strain gauge lies in its maturity.

- High Accuracy: You get precise data. Torque sensor accuracy is typically much higher with strain gauges compared to magnetic methods, often reaching 0.1% or better.

- Cost-Effectiveness: Compared to complex optical or SAW systems, strain gauges provide professional-grade results without breaking the budget.

- Versatility: Whether you need a static torque sensor for testing fasteners or a dynamic one for a motor, this tech scales well.

We often hear concerns about durability—specifically regarding gauge bonding quality and potential sensitivity drift.

Here is the reality: if you are trying to bond gauges yourself without a clean room and proper curing ovens, yes, you will have issues. However, our industrial shaft torque transducers are professionally bonded and sealed (often to IP65 or IP67 standards). This eliminates peeling and minimizes drift caused by humidity or temperature shifts. As long as you stay within the rated torque and fatigue limits, these sensors are incredibly rugged.

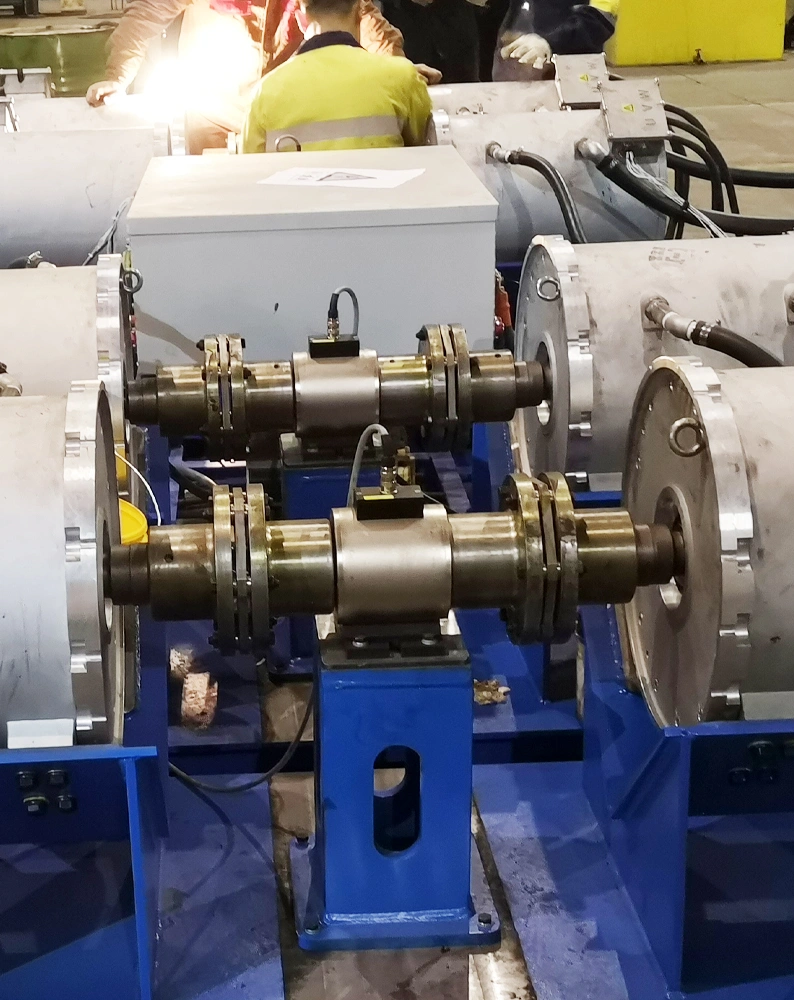

Selecting the Right Strain Gauge Torque Sensor

Choosing the correct sensor can make or break your test rig or production line. I’ve seen too many engineers overpay for precision they don’t need or, worse, buy a unit that physically won’t fit their drivetrain. Whether you are dealing with a complex dynamic torque measurement setup or a simple quality check, the process boils down to a few logical steps.

4 Step Selection Guide

To get the right match for your application, I always recommend following this four-step workflow:

1. Define the Motion: First, ask yourself if the part is moving.

- Non-rotating: If you are measuring torque on a casing or a fastener, you need a reaction torque transducer. These are static, cheaper, and generally more robust.

- Rotating: If the shaft spins, you need a rotary torque sensor. You’ll then need to decide if you need a slip ring model or a non-contact torque telemetry system for higher speeds.

2. Determine Mounting Style: How will this integrate into your machine?

- Do you have a free shaft end?

- Is it an inline installation?

3. Specify Range and Accuracy:

- Torque Range: Select a sensor where your normal operating torque is about 60-80% of the sensor’s full scale. Don’t size it for the breaking point; size it for the working point.

- Accuracy: For general industrial monitoring, standard accuracy is fine. For lab-grade testing, look for high-precision classes.

4. Environmental Check: If you are in a dirty US industrial plant or an outdoor oil field, verify the IP rating. A standard bonded foil strain gauge is tough, but moisture protection is critical.

Mounting Options: Finding the Mechanical Fit

Here is a quick breakdown of the common styles we deal with:

- Shaft-to-Shaft: Inline motor testing, pump monitoring. Requires flexible couplings to accommodate misalignment.

- Flange Mount: High-stiffness requirements, shorter axial length. Flange mount torque transducers handle extraneous loads (bending/thrust) better than shaft types.

- Square Drive: Fastener testing, nut runners, torque wrench calibration. Designed for quick tool changes; easy to drop into existing sockets.

- Custom Couplings: OEM machinery with tight space constraints.We can often modify the shaft ends to mate directly with your gearbox or motor.

Torque Sensor Calibration Standards

You cannot guess with torque. Torque sensor calibration establishes the relationship between the electrical signal (mV/V) and the physical force. We recommend recalibrating once a year or after any significant overload event.

- Traceability: Ensure your calibration is traceable to national or international standards (like NIST in the US). This is non-negotiable for ISO compliance.

- Shunt Calibration: Many of our sensors come with a shunt cal feature. This simulates a known load on the Wheatstone bridge, allowing you to verify the signal chain without applying physical torque.

FAQ

Sino-Inst Strain Gauge Torque Sensor Solutions

At Sino-Inst, we understand that every test rig and industrial application has its own set of demands. We don’t just sell sensors; we provide complete torque measurement solutions tailored to your specific setup. Whether you are running high-speed dyno tests or static fastener checks, our lineup covers both dynamic torque measurement and static applications with industrial-grade reliability.

We offer a comprehensive range of sensors designed to handle everything from delicate lab work to heavy-duty industrial monitoring. From micro-torque measurements (0.1 N·m) up to massive high-capacity units (500,000 N·m) for heavy machinery. Our integrated electronics offer standard analog outputs (mV/V, 4-20mA, 0-10V) and digital interfaces (RS485, CANopen) for seamless integration with your PLCs and DAQ systems.

A significant portion of our business involves customizing solutions for US-based OEMs and specialized test facilities.

Need a quote or a custom drawing for your application? Would you like me to help you select the specific model series that fits your torque range and speed requirements? Feel free to contact us anytime.

-1.jpg)