Compare the G Thread vs NPT thread used in pressure transmitters. Understand the difference between 55-degree parallel threads and 60-degree tapered threads to ensure a secure seal.

Pressure transmitters utilize various process connection methods, such as threaded, flanged, and clamped connections. Threaded connections are the most commonly used. When adding or replacing a pressure transmitter, it is essential to confirm the thread size. Common examples include 1/2″ NPT, 1/4″ NPT, G1, G1/4 threads, and some special threads like 9/16-18″ UNF, etc.

Confirming the pressure transmitter‘s thread size ensures successful installation and effective sealing.

Common Thread Types

| Category I: Fastening Threads | Category II: Drive Connection Threads | Category III: Pipe Threads |

| 1. Metric General Purpose Threads (M) 2. Unified National Threads (UN) 3. British Standard Whitworth Threads (B.S.W, B.S.F, Whit.S., and Whit.) 4. Metric Fine Threads (S) 5. Metric Aerospace Threads (MJ) 6. Unified National J-Threads (UNJ) | 1. Metric Trapezoidal Thread (30°) (Tr) 2. American Trapezoidal Thread (29°) (ACME) 3. Metric Buttress Thread (3°/30°) (B) 4. American Buttress Thread (7°/45°) (BUTT) 5. British Standard Buttress Thread (7°/45°) (B.S. Buttress) | 1. British Standard Pipe Threads (55°) a. General Sealing Pipe Threads (R) b. Non-Sealing Pipe Threads (G) c. Japanese/Korean Legacy Pipe Threads (PT, PF) 2. American Standard Pipe Threads (60°) a. General Sealing Pipe Threads (NPT, NPSC) b. Dry-Seat Pipe Threads (NPTF, NPSF, NPSI, PTF-SAE SHORT) c. Non-Seat Pipe Threads (NPSM, NPSL, NPTR, NPSH, NH, NHR) 3. General-Seat Metric Pipe Threads (Mc, Mp) |

What is a G Thread?

G threads are non-threaded sealing pipe threads with a 55-degree thread angle, primarily used for connecting pipes. They are available in straight-through bodies (constant diameter) and parallel straight threads.

Functions and sealing methods of G-threads:

- Parallel design: The pipe diameter remains constant along its entire length; it does not taper gradually.

- 55° thread angle: The thread is cut at a 55-degree angle, with rounded peaks and valleys, which distinguishes it from the sharper American profile.

- Sealing method: Because the threads cannot wedge together to form a seal, G-thread seals are not self-sealing. You must use adhesive washers, O-rings, or sealing gaskets to achieve a leak-proof connection.

G-thread is a common configuration for hydraulic fittings and pressure sensors in Europe, Asia, and Australia.

What is an NPT Thread?

NPT stands for National Pipe Taper, defined in ANSI/ASME B1.20.1. Unlike straight threads (G), NPT uses a tapered design.

The most distinctive feature of NPT threads is their tapered thread profile. The thread diameter gradually decreases from the tip to the tip, decreasing by 0.75 inches per foot (a ratio of 1:16).

Technical details of NPT threads:

- Thread angle: It uses a 60° thread angle (different from the 55° used in G threads).

- Outline: The peaks and valleys of the wire are flattened (truncated), rather than rounded.

- Sealing method: NPT threads use an interference fit. When tightening the threaded pressure transmitter or pipe, the threads interlock through mechanical compression, forming a seal.

- A good seal requires the use of PTFE tape or tapered thread sealant.

In the North American market, including the United States and Canada, the most common sizes are 1/4 NPT and 1/2 NPT. Whether you are dealing with oil and gas pipelines or residential pipelines, these are the most commonly used industrial pipe thread specifications for pressure sensors and fittings.

G Thread vs NPT

Based on our introduction above, we have summarized the differences between the two.

| Features | G Thread | NPT thread |

| Thread shape | Parallel (Straight) | Tapered (conical) |

| Thread angle | 55° | 60° |

| Sealing method | Requires O-ring/Gasket | Thread interference (wedge) |

| Does it require sealant? | No (Use Washer) | Yes (tape or glue) |

| Reusability | Excellent | Limited (wire deformation) |

| Primary area | Europe, Asia, Worldwide | USA, Canada |

| Visual when assembled | No exposed thread | Visible thread or PTFE tape |

How to Distinguish Them?

When compared side-by-side, the difference between the two threaded connection types is obvious. NPT threads are slightly tapered, while G-type connections are straight. G threads have a small protrusion (joint) at the end for securing the gasket.

However, visual identification can be inaccurate. You can use tools for accurate judgment. Before you begin, prepare the following tools:

- Calipers: Used to measure the outer diameter (OD).

- Pitch gauge: Used to check the number of threads and the angle (60° vs. 55°).

- Reference chart: Standard pipe thread comparison table.

We can accurately identify the thread type of a pressure sensor by following these steps:

- Measure the outer diameter (OD): Use vernier calipers.

- For NPT, measure the OD value at the widest point of the engaging thread.

- For G threads, due to their uniform dimensions, measurements can be taken at any point along the thread.

- Check the thread pitch: This is crucial for success.

- Calculate the threads per inch (TPI) using a pitch gauge.

- For example: A 1/4 NPT thread has a thread density of 18 TPI, while a G 1/4 thread has a thread density of 19 TPI. They look similar but will not seal.

- Verify the angle: Check that the special blade on the pitch gauge matches the groove of the thread.

- 60 degrees for NPT.

- 55 degrees for G threads.

Choosing the Right Thread for Your Pressure Transmitter

Of course, whether it’s a G-thread or an NPT thread, ultimately only the thread that matches the operating conditions is the most suitable for the pressure transmitter.

If you are replacing an existing pressure transmitter or gauge, you can configure a matching thread based on the existing pressure process connection interface dimensions.

If you are installing a new pressure transmitter, consider both the pressure rating and the frequency of disassembly and reassembly. For extremely high-pressure applications, the interference fit of NPT is reliable. However, G-threads with adhesive washers typically provide a cleaner, leak-free seal without causing port cracking due to overtightening.

If you require frequent sensor disassembly for cleaning or calibration, G-threads are a better choice. G-threads do not rely on thread deformation for sealing and can therefore be reused. NPT threads will wear after repeated tightening.

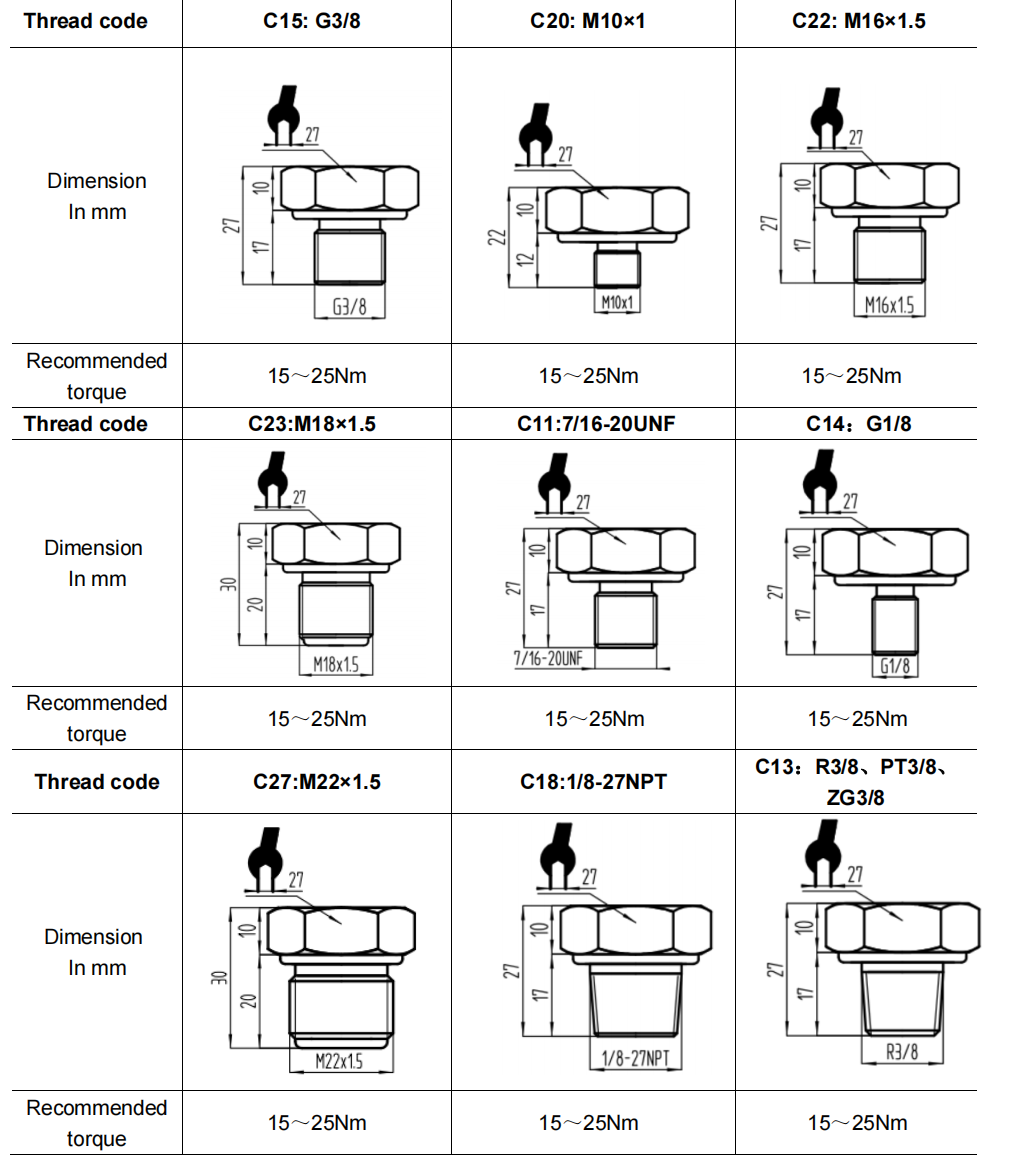

Sino-Inst’s pressure experts are proficient in measurement standards and pressure transmitters from various countries. Our pressure transmitters can be configured with various threads. The following figure shows some common thread sizes and installation torque references.

More Pressure Measurement Solutions

What is a Dynamic Pressure Sensor? Vs. Static

Case – High Frequency Dynamic Pressure Sensor: 0-200 kHz

High Temperature Pressure Transducers & Cooling Elements

What Is a Pressure Switch? Read Before Buy and Use

More Powerful Pressure Transmitter with Diaphragm Seal and Capillary

Sea Water Resistant Pressure Sensors

When we customize pressure transmitters for our users, we typically include the mounting thread dimensions on the nameplate. This allows you to clearly and accurately determine the mounting thread dimensions of our pressure transmitters.

If your pressure transmitter requires special threads or flange process connections, we support customization. Please feel free to contact our sales engineers at any time!

-1.jpg)