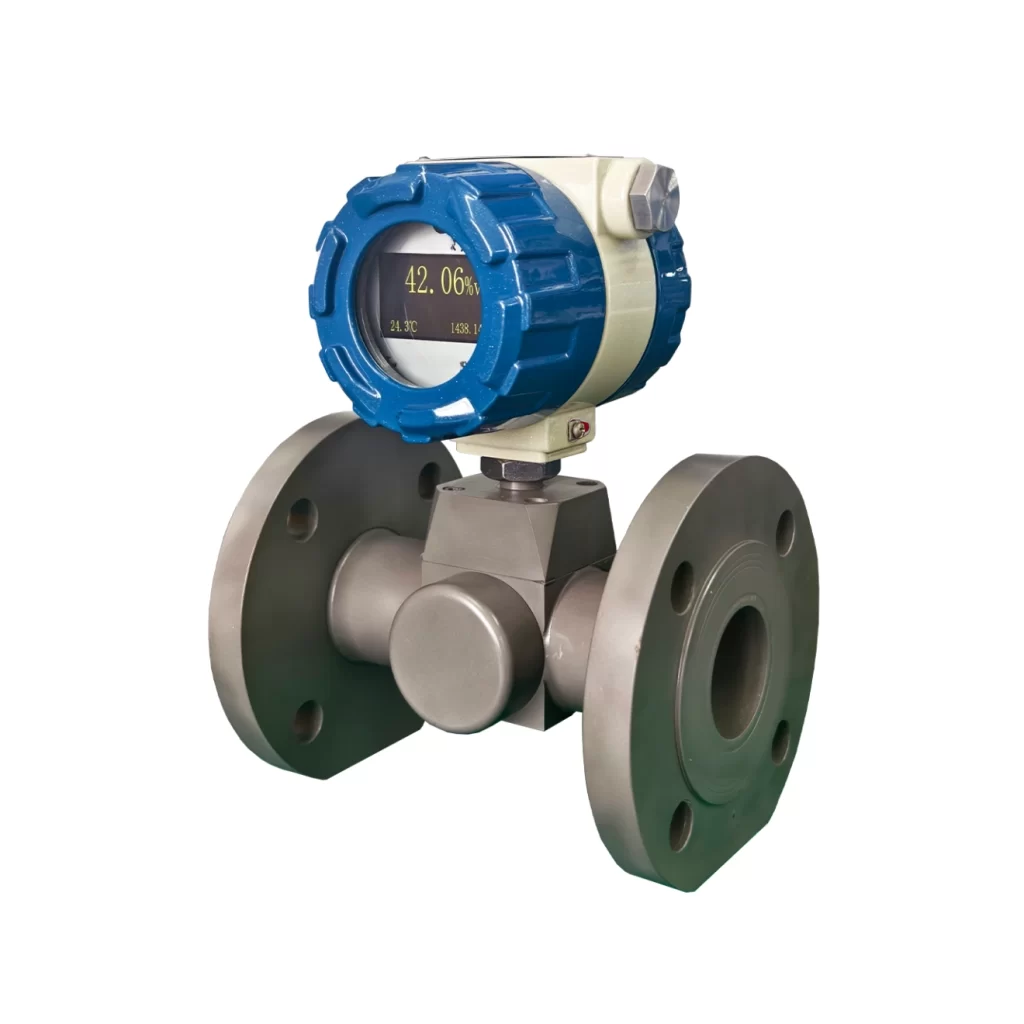

The Ultrasonic Density Meter/Concentration Meter utilizes the principle of ultrasonic sound velocity measurement and integrates multiple detection technologies for online, precise measurement of solution concentration, density, solid content, and Brix value.

Ultrasonic detection is unaffected by the turbidity, color, and conductivity of the medium, nor is it affected by flow conditions or impurities. The built-in high-precision resistance temperature detector and reliable sensor design ensure real-time, accurate measurements.

Features

Technical Specifications

| Concentration accuracy | ±0.1%, ±0.3%, ±0.5% |

| Density accuracy | ±0.0005 g/cm³, ±0.001 g/cm³, ±0.005 g/cm³ |

| Sound velocity range | 300 m/s ~ 3000 m/s |

| Sound velocity accuracy | 0.01 m/s |

| Medium temperature | -20℃ ~ +60℃, High-temperature type: -20℃ ~ +120℃ |

| Temperature accuracy | 0.01℃ |

| Ambient temperature | -30℃ ~ +50℃ |

| Relative humidity | 0 ~ 98% (non-condensing) |

| Protection class | IP65 |

| Operating pressure | ≤2.0 MPa |

| Explosion-proof marking | Ex db ib IIC T6 Gb |

| Analog output | 4 ~ 20 mA DC, maximum 750Ω load |

| Communication method | RS485 (optional) |

| Power supply | 24V DC |

| Display | 128×64 dot graphic LCD |

Ultrasonic Density Meter/Concentration Meter Measurement Principle

An ultrasonic transmitting probe emits a beam of ultrasonic signals. The signal travels through a liquid of a certain concentration and reaches another ultrasonic receiving probe on the opposite side. The total transmission time of the ultrasonic signal is measured, and the distance divided by the time gives the ultrasonic sound velocity.

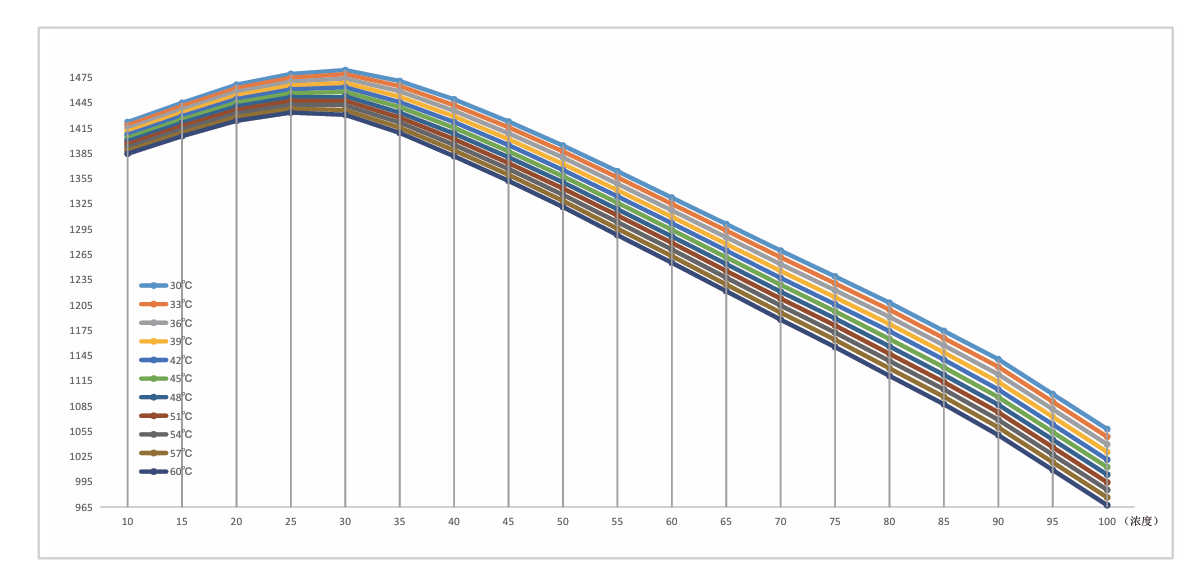

Within a certain concentration or density range, the propagation speed (v) of the ultrasonic signal in the liquid medium is a function of concentration or density (c) and temperature (t), as shown in the figure.

The above figure shows the sound velocity-concentration dependence for 10-100 wt% alcohol.

When several media with different sound velocities are mixed, there is a definite relationship between sound velocity and concentration. After calibration and temperature compensation, the ultrasonic concentration and density analyzer can accurately measure the concentration of multi-component liquid media.

Based on the same principle, sound velocity and density are also highly correlated, thus allowing for accurate measurement of the density of single-component or multi-component liquid media.

Featured Applications

| Industries: | Applications |

| Chemicals | • Concentration and Density: Alkalis, acids, solvents, salt solutions, emulsions, and suspensions • Polymerization: Synthetic rubber, butadiene solutions, resins, polyacrylates, polyvinyl acetate, and polystyrene • Crystallization: Fertilizers/salts, reaction monitoring • Phase Detection: Butanol, tyrosol, epoxy resins, ethyl acetate, oil-in-water emulsions, peracetic acid, silicone resin phases, and wax melting • Multicomponent Analysis: Methanol/formaldehyde, sodium hydroxide/sodium chloride, sulfuric acid/fuming sulfuric acid |

| Pharmaceuticals | • Concentration and density: solvents, culture media, active ingredients, emulsions, and suspensions • Crystallization: active ingredients and culture media • Phase detection, reaction monitoring |

| Biotechnology | • Fermentation: Formula and feed control • High-performance liquid chromatography (HPLC): Eluent control and solvent concentration |

| Brewing Industry | • Filtration tank: Extraction • Wort tray: (Extraction volume) • Filter: Beer wort concentration • Filter, mixing: Initial beer wort concentration, alcohol content, Brix |

| Food Industry | • Concentration: Glucose, acetic acid, fruit extract, pectin, dextrose, coffee extract, condensed milk, milk, milk powder, whey, oil, fruit juice, sorbitol, starch, soy sauce, and palm oil |

| Sugar Industry | • Concentration: Diluted and concentrated juices, liquid sugar, crystals, molasses, and syrups |

| Steel | • Pickling tanks: Acids and alkalis • Plating tanks and cleaning solutions • Concentration control of rolling oils and drawing oil emulsions |

| Petrochemicals | • Concentration: water content, (bio)fuels, additives, liquefied petroleum gas and biogas, and hydrocarbonization • Gas scrubber • Phase separation |

| Semiconductors and Optoelectronics | • Etching, coating, and cleaning solutions • Photoresist quality control • Measurement of coating emulsion and suspension concentrations |

| Mechanical Engineering | • Concentration: Rolling oils and cleaning fluids, coolants and lubricants, drawing oils and antifreeze |

| Equipment Engineering | • Process control and monitoring: Mixing and injection systems, distillation columns, evaporators, extraction equipment, crystallizers, separators, gas scrubbers, fermentation tanks, and filters. |

Installation

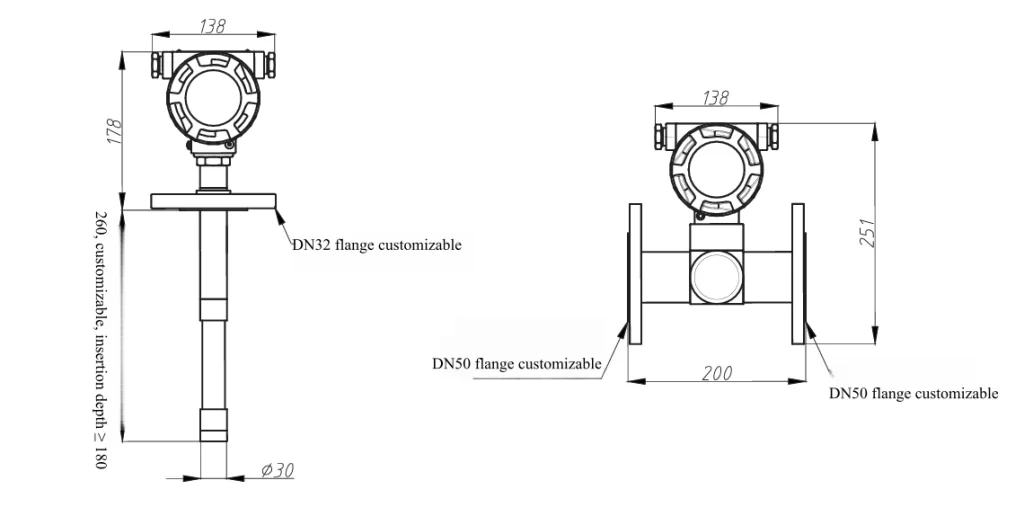

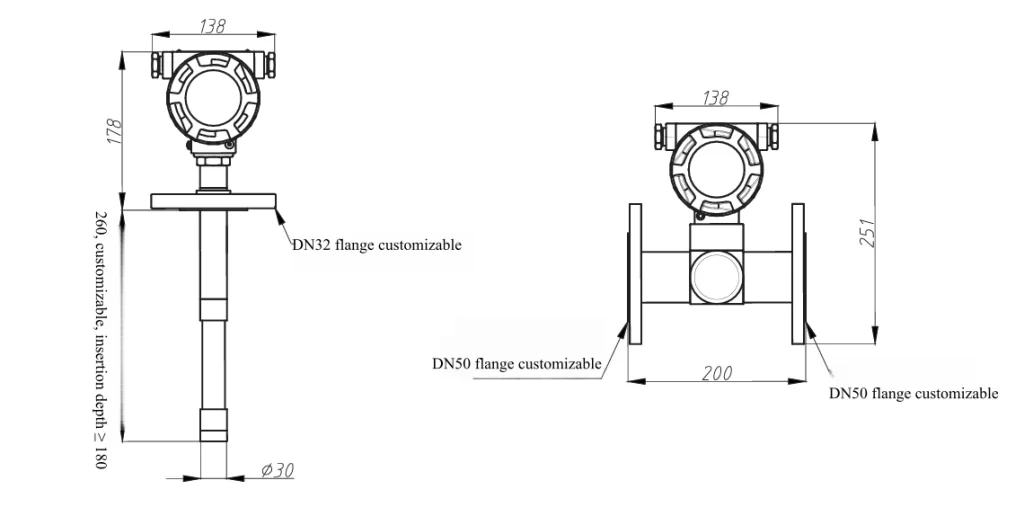

The ultrasonic density meter/concentration meter can be installed using a flanged pipe connection or an insertion-type mounting.

More Density-Concentration Meters

The ultrasonic density meter/concentration meter measures liquid concentration using the ultrasonic sound velocity method. This is based on the principle that the speed of sound through a liquid varies with concentration and temperature. Each liquid is tested individually to create a unique sound velocity data model with temperature compensation. Combined with a unique algorithm, the instrument offers high measurement accuracy and excellent long-term stability.

Sino-Inst supports customization of density meters/concentration meters, including wetted materials, dimensions, and measurement range. If you require liquid density or concentration measurement, please feel free to contact our sales engineers!

Ultrasonic Density Meter/Concentration Meter - Sino-Inst

The Ultrasonic Density Meter/Concentration Meter utilizes the principle of ultrasonic sound velocity measurement and integrates multiple detection technologies for online, precise measurement of solution concentration, density, solid content, and Brix value.

Product SKU: Ultrasonic Density Meter Concentration Meter

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)