An inline viscosity meter is an instrument specifically designed for measuring the viscosity of liquids. It works by utilizing the micro-vibrations generated by a vibration system to measure the resistance of the liquid.

The measurement range of an inline viscosity meter is generally between 0 and 10^9 MPa·s, and it is widely used in various manufacturing enterprises and scientific laboratories. Inline viscosity meters can be used to measure the viscosity of Newtonian fluids such as petroleum products, hot melt adhesives, food and beverages, liquid slurries, paints, coatings, latexes, and various chemical solutions used in laboratories.

Features

Technical Parameters

| Measured Medium | Various liquid media |

| Display Method | LCD backlight display of temperature and viscosity |

| Measurement Range | 0~10^9MPa ·s; 0-500mpa.s;0~1000mpa.s;0-5000mpa.S 0-10000mpa.s;0-100000mpa.s Can be calibrated to a specific range according to usage. |

| Measurement Accuracy | ±1% (standard conditions), dynamic viscosity, resolution: 0.1, repeatability: 1 |

| Temperature Accuracy | 0.20% |

| Ambient Temperature | -30°C~80°C |

| Pressure Range | <25Mpa |

| Sensor Temperature Range | <500°C |

| Signal Response Time | 2s |

| Power Supply Voltage | 24V DC |

| Output Signal | 4~20 mA, Modbus-RTU protocol 485 interface |

| Protection Level | IP66 |

| Explosion-proof Standard | Ex db Ic T6 Gb |

| Calibration | Standard sample liquid |

| Viscosity Unit | P, CP, mpa.s, pa.s.mm2/s, m2/s. st. cst. s |

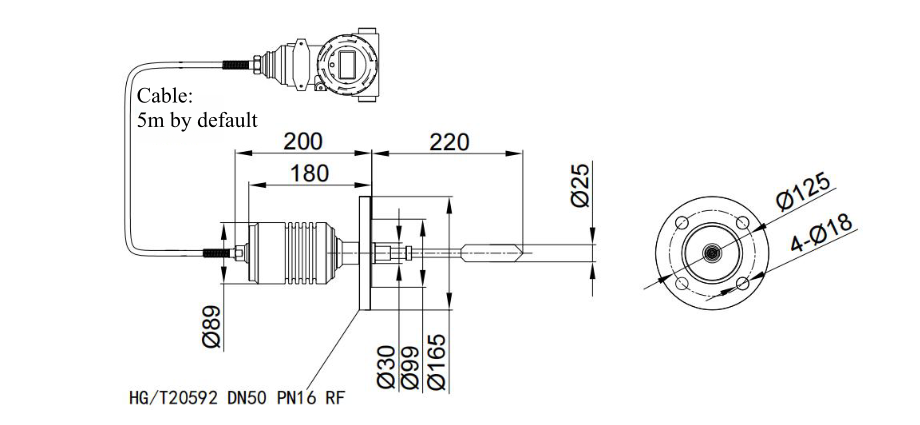

| Connection Method | Flange, chuck or threaded mounting |

| Wetted Materials | 316 stainless steel (standard); other materials optional |

Inline Viscosity Meter Working Principle

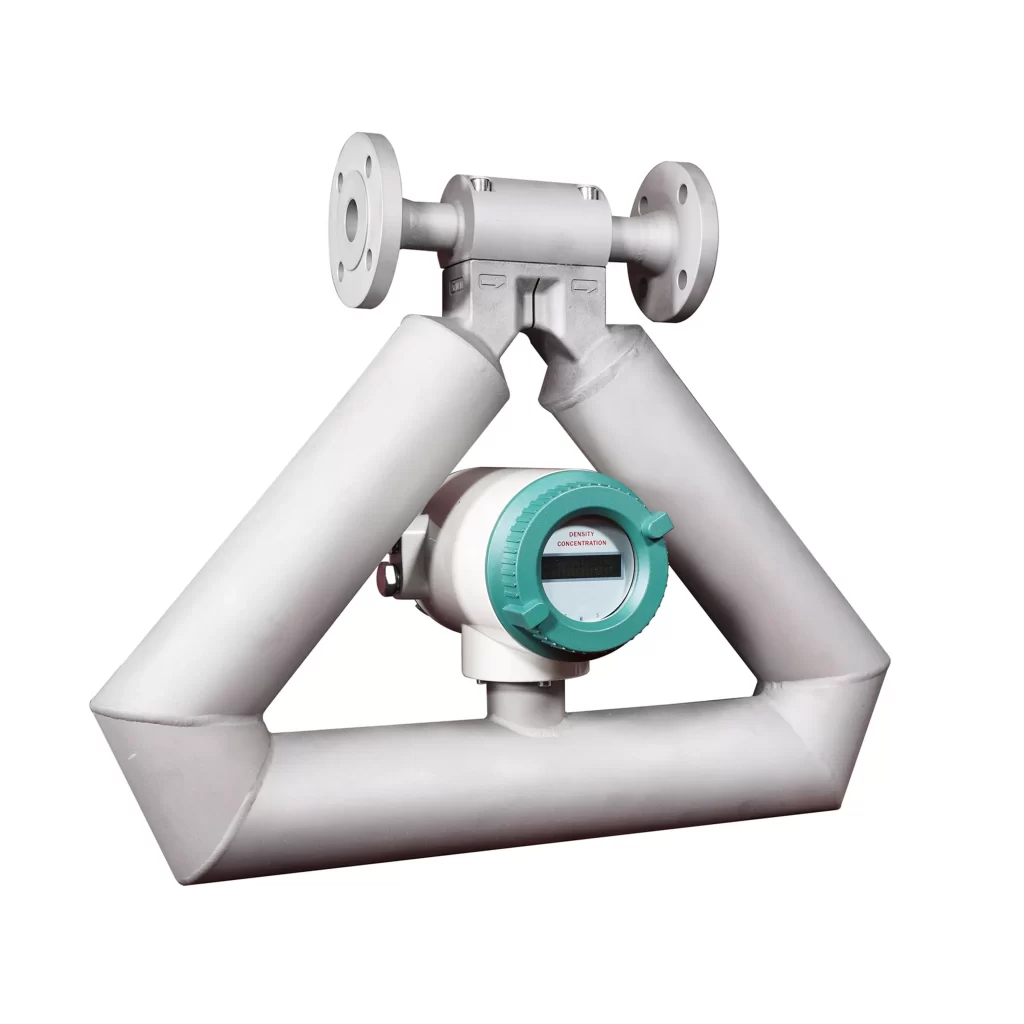

The inline viscometer operates on the principle of sensor probe vibration.

The main body of the inline viscometer consists of four parts: a detection rod, a drive chamber, an explosion-proof instrument box, and a shielded cable connecting the drive chamber and the explosion-proof instrument box.

The sensor probe vibrates at a specific frequency and amplitude in the liquid. Due to the viscous damping of the liquid during vibration, the probe’s amplitude decreases. To maintain consistent amplitude before and after the probe’s interaction with the liquid, the energy lost due to damping needs to be replenished.

This replenished energy is related to the liquid’s viscosity. By measuring this replenished energy, the viscosity of the liquid can be calculated using a specific relationship. Finally, the internal processor converts this into a displayable viscosity reading.

Industrial Applications of Viscometers

Vibratory online viscometers are mainly used for process control and measurement in the production of paints, resins, rubber, crude oil, dairy products, and adhesives. They are particularly important in production processes requiring strict control of fluid viscosity.

Applicable Industries:

- Petroleum: Petrochemical products, oil and gas production, oil transportation, asphalt, mud and sludge, fuel oil, polymers.

- Chemicals: Polymers, resins, solvents, inks and pigments, lubricants, adhesives.

- Building Materials: Paints, ceramics, coatings, glass industry.

- Food: Fermented products, candied fruits, syrups, food processing, emulsions, fruit juices and teas.

- Papermaking: Starch sizing, black pulp, green pulp.

- Metallurgy: Mineral processing.

- Water Conservancy: Water treatment.

- Power industry.

- Pharmaceutical industry.

Temperature Compensation

The viscosity sensor incorporates a high-precision PT1000 platinum resistance sensor with a resolution of 0.01℃ and an accuracy of 0.1℃, requiring no calibration. This allows for real-time detection of liquid temperature changes, which can be used to calculate the compensation coefficient for the liquid’s temperature effect.

There is a linear relationship between liquid temperature and viscosity. Based on temperature change data, the compensation coefficient for the liquid’s temperature effect can be calculated to accurately reflect the influence of temperature on the liquid’s viscosity.

The temperature change of the fork material also affects the corresponding detection results. By detecting real-time temperature values and considering the coefficient of temperature-dependent rigidity of the probe, the temperature compensation of the vibrating tube material is added to the overall effect of temperature on liquid density, enabling a truly accurate measurement of the corresponding true viscosity value.

Installation

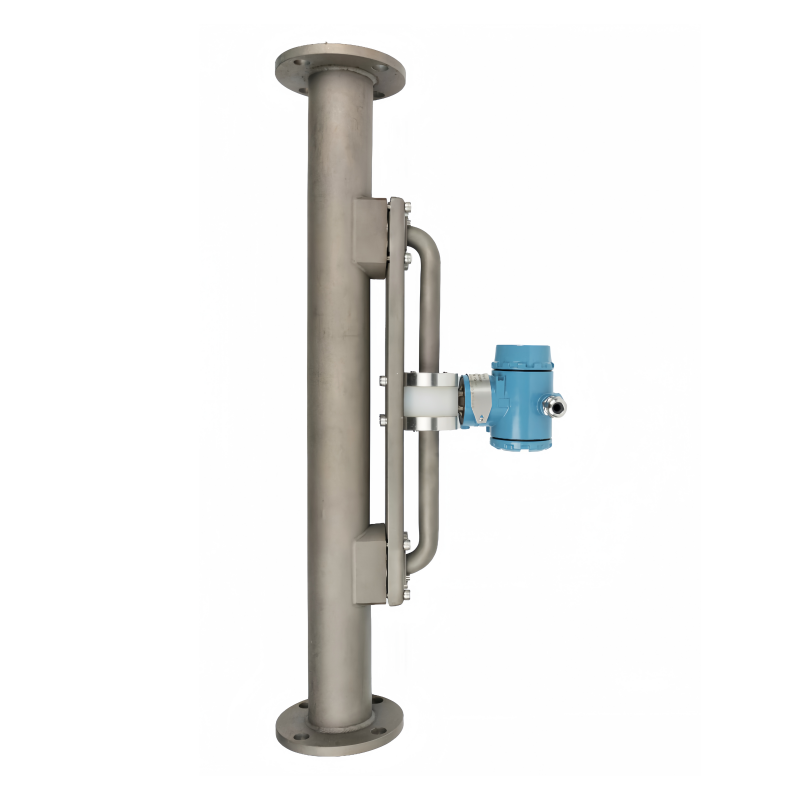

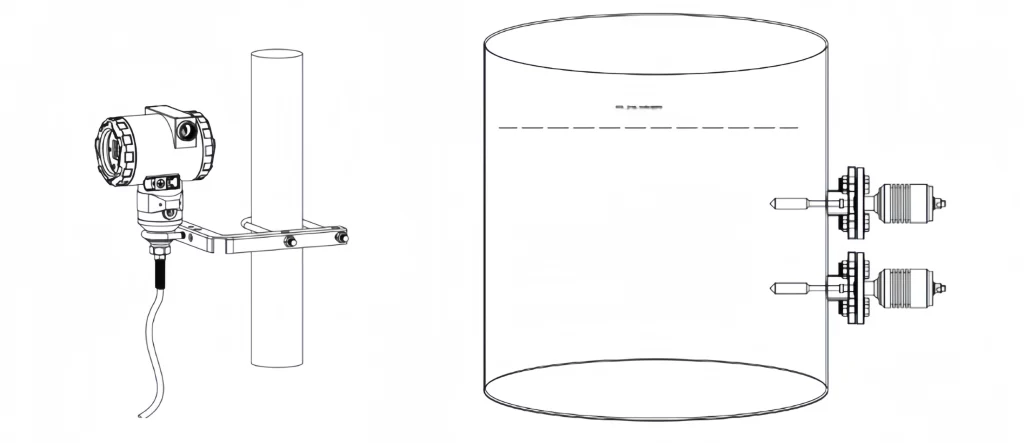

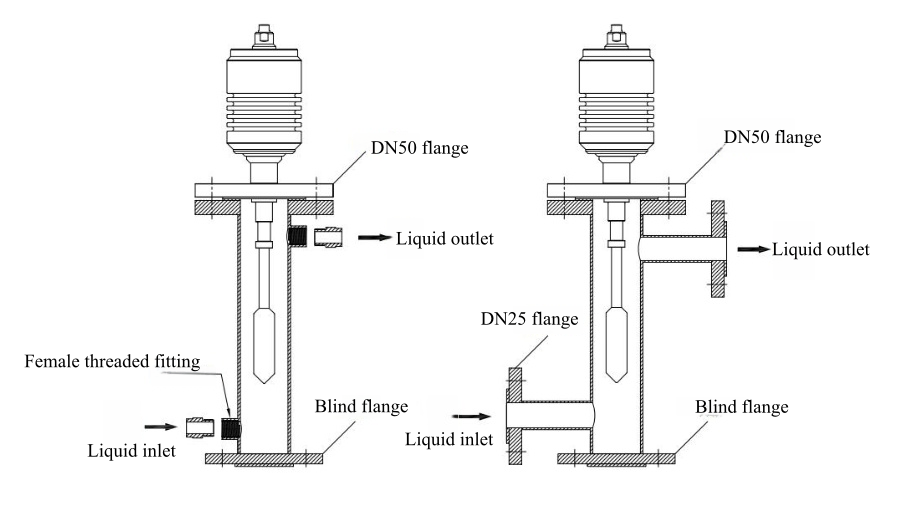

Inline Viscosity Meters can be installed on tanks or pipelines.

Tank Installation

- Due to the limited design length of the instrument, vertical installation is not possible; side installation is recommended.

- When side-mounted, the cone must be fully inserted into the tank.

- If there is agitation in the tank, a protective cover is required to prevent surge interference. The probe should be kept as far away from the agitator impeller as possible.

- This instrument cannot be used with agitation methods involving agitation.

- Due to the characteristics of the medium, some media will decompose and release bubbles when stationary. These bubbles adhering to the cone will affect the measurement.

- For media prone to crystallization and scaling, the probe condition needs to be checked regularly, and timely cleaning and maintenance are required.

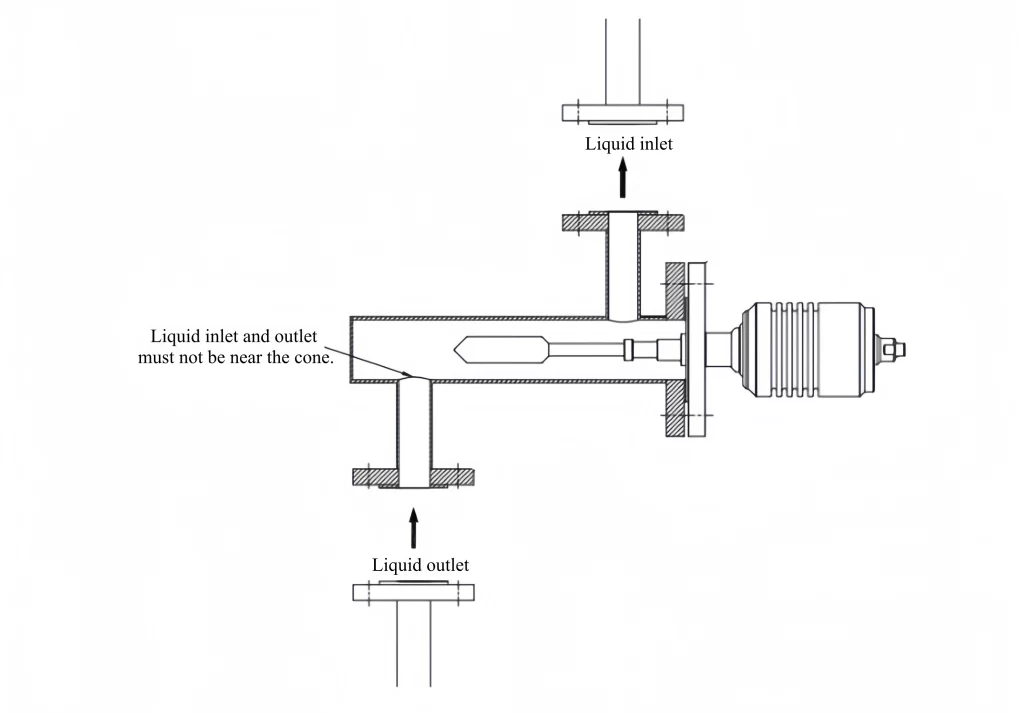

Vertical Pipe Installation

The cone must be fully inserted into the pipe; and the distance between the cone and the opposite pipe wall must be >20mm. (If the pipe diameter cannot meet this requirement, a tee expansion should be used.)

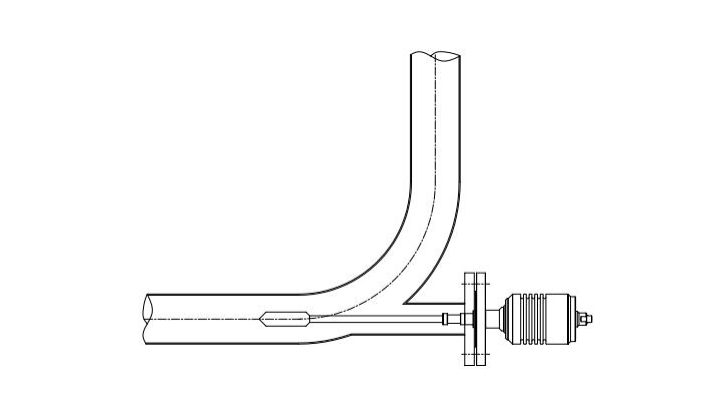

Bend Installation

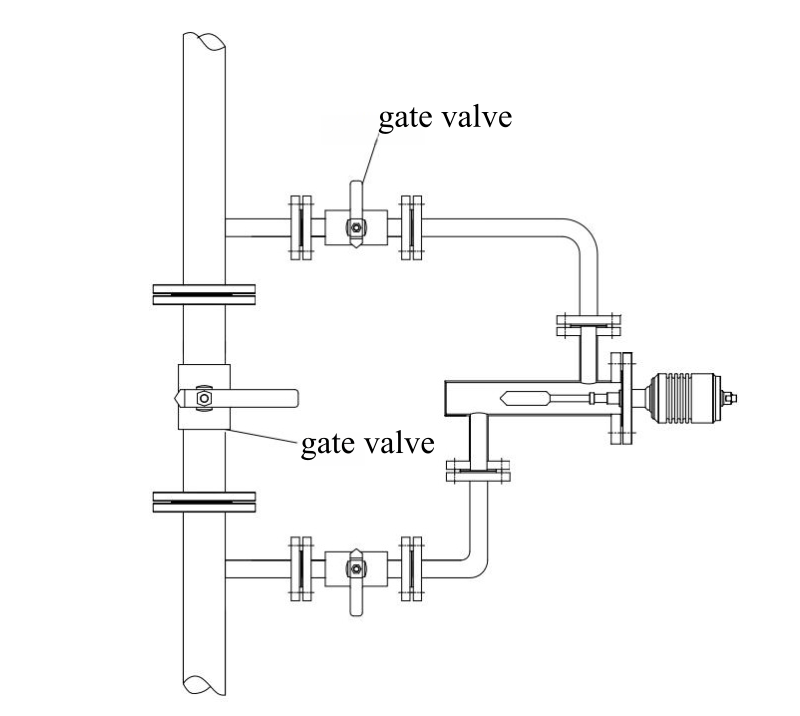

Bypass Installation

- Using a bypass for horizontal pipelines may result in incomplete liquid filling at the tee of the instrument, affecting the measurement.

- If the bypass flow is poor, a regulating valve needs to be added to the main line to increase the pressure difference between the bypass inlet and outlet, ensuring bypass flow.

Horizontal Pipe Installation

- For horizontal pipes, it is recommended to install the instrument side, ensuring the cone is fully inserted into the pipe; and the distance between the cone and the opposite pipe wall should be >20mm. (If the pipe diameter cannot meet this requirement, use a tee with enlarged diameter).

- Keep the pipe full, ensuring the cone is always submerged in the liquid.

- For flow velocities >0.5m/s, use an enlarged tee or bypass installation.

More Viscosity and Concentration Measuring Equipments

Online measurement of liquid viscosity provides data on its rheological behavior, offering crucial guidance for predicting process control, conveyability, and operability during product use.

Sino-Inst’s viscometers support customized parameters, including those for special conditions such as high temperature and high pressure. We provide online fluid viscosity measurement services to users in the United States, the United Kingdom, Singapore, Indonesia, and other countries. This ensures optimal process operating environment and product quality, thereby improving production efficiency. If you require liquid viscosity measurement, please feel free to contact us!

Inline Viscosity Meter 0~50000mpa.s | Sino-Inst

An inline viscosity meter is an instrument specifically designed for measuring the viscosity of liquids. It works by utilizing the micro-vibrations generated by a vibration system to measure the resistance of the liquid.

Product SKU: Inline Viscosity Meter

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)