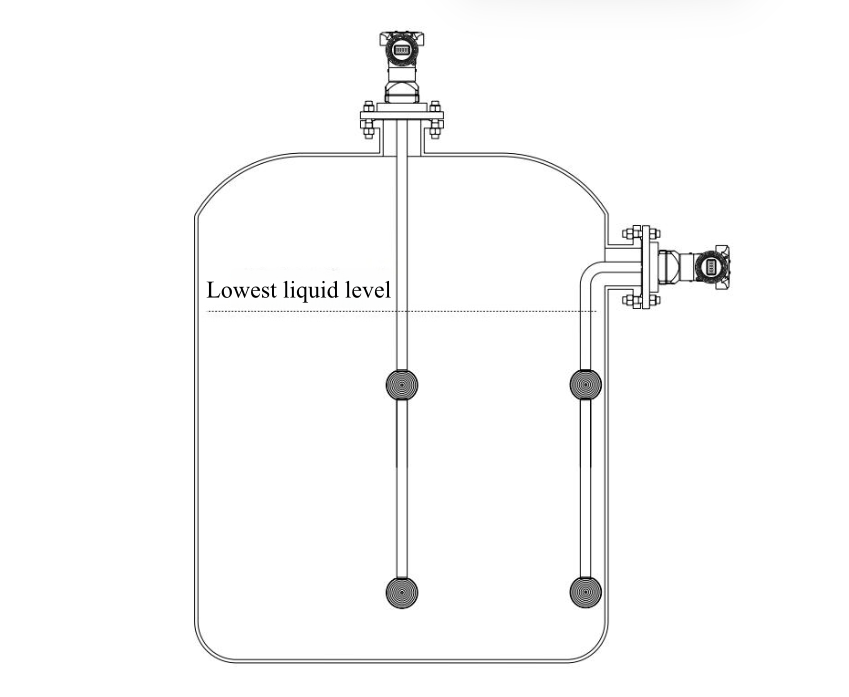

The insertion-type differential pressure density meter can be installed on the top or side of the tank. The differential pressure digital density meter uses the differential pressure principle to calculate the density value based on the differential pressure value of the medium at a certain vertical distance. It automatically compensates, offering high accuracy, good reliability, and simple installation and use.

The online density meter generates a corresponding 4-20mA signal based on the concentration and density, allowing for remote calibration and monitoring via digital communication. Intelligent differential pressure density meters are widely used in industries such as food and petrochemicals.

Features

- Utilizing a multi-parameter flat-diaphragm flange sensor, it enables online density measurement of various liquids or liquid mixtures.

- Featuring an integrated two-wire transmitter design with no moving parts for simplified maintenance.

- Features a local digital LCD display.

- Easy to install and use—simply immerse in liquid to display readings.

- Suitable for both flowing and stationary liquids, compatible with pipeline and tank installations.

- Customizable density units facilitate standard density conversions across industries.

- Enables continuous online liquid density measurement without process interruption, directly applicable for production process control.

Specifications

| Measuring range | Customizable within 0-3.0g/cm³ |

| Permissible temperature: | 0-100℃; 0-200℃; 0-300℃ |

| Operating voltage: | 12-45VDC |

| Electrical interface: | 1/2NPT or M20×1.5 |

| Output: | 4-20mA (four-wire) |

| Communication: | Hart Protocol |

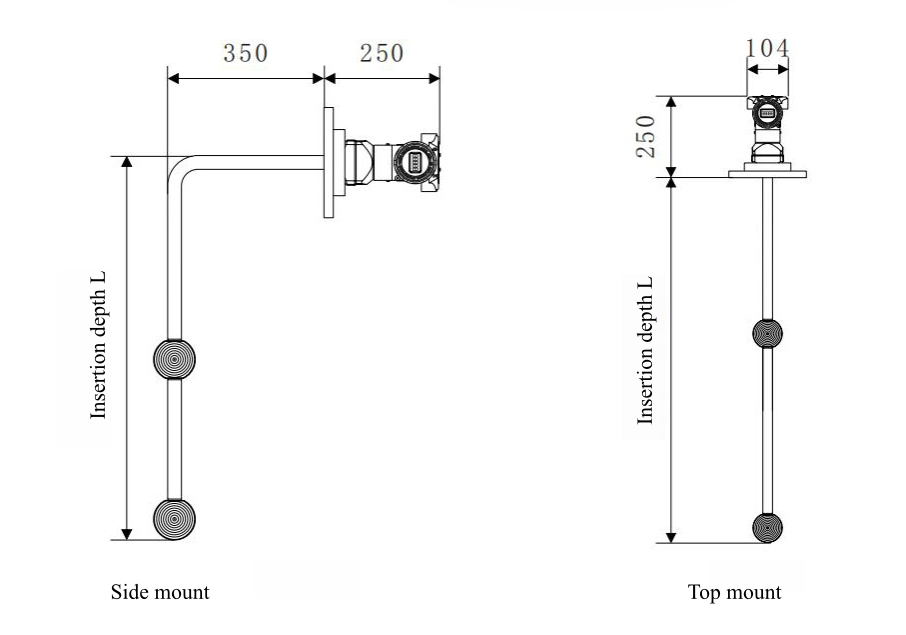

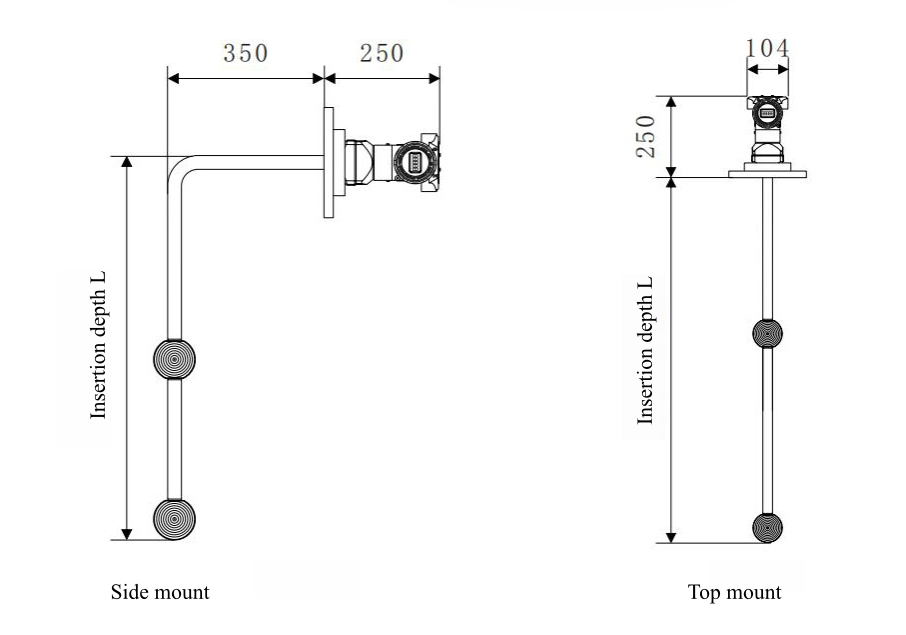

| Installation method: | Flanged top or side mounting, dimensions can be customized. |

| Insertion length | 500mm; 800mm; or custom length |

| Flange specifications | 3″ or DN80 4″ or DN100 Other custom sizes |

| Filling fluid | DC200 silicone oil, DC704 silicone oil, olive oil, or other specifications. |

| Diaphragm material | 316L Hastelloy, Tantalum, Others |

| Flange material | SUS304, SUS316, PTFE |

| Wetted material | 304, 316, Titanium |

| Explosion-proof rating | Intrinsically Safe ExiaIICT6, Explosion-Proof ExdIIBT4 |

Installation

- The product must be inserted vertically from the top, as shown in the installation diagram; the perpendicularity to the ground should not exceed 5 degrees. If the installation is not vertical, or if the local gravitational acceleration deviates from the standard gravitational acceleration, deviations will occur. How to eliminate these deviations will be explained later.

- When installing from the side, ensure the straight section of the flange can be easily inserted.

- After opening the cover of the electrical box, tighten it during reinstallation to ensure tight contact with the sealing O-ring. If not tightened, moisture will enter the electrical box, affecting the normal operation of the circuit.

- The densitometer casing must be effectively grounded.

- The installation location should be as far away as possible from frequency converters or high-power motors. If necessary, take isolation measures and use a shielded power cord.

- After installation, zero the tank when empty, so that the density value displays 0 g/cm³.

Featured Applications

Differential pressure online density meter, employing a dedicated density sensor, performs online density measurement of various liquids or liquid mixtures, directly reading the density value and outputting a 4-20mA DC signal, with HART communication protocol.

Widely used for density measurement of general liquids and in the petrochemical industry:

- Widely applied in petroleum, refining, oil blending, and oil-water interface detection;

- Sanitary density meters can be used in the food industry for various edible liquids and soft drink processing;

- Corrosion-resistant density meters can be used for measuring the density of acid and alkali solutions, as well as chemical substances such as urea, cleaning agents, ethylene glycol, acids, alkalis, and polymers.

More density measurement instruments

Differential pressure density meters can meet the measurement needs of high-temperature, high-viscosity, and corrosive media. They are cost-effective, simple, practical, require minimal maintenance, and offer stable and reliable operation for liquid density measurement. Suitable for detecting the density of flowing or stationary liquids. Hygienic, high-temperature, and corrosion-resistant models are available.

If you require density measurement, please feel free to contact us for a customized solution.

Differential Pressure Density Meter - Insertion Type

The insertion-type differential pressure density meter can be installed on the top or side of the tank. The differential pressure digital density meter uses the differential pressure principle to calculate the density value based on the differential pressure value of the medium at a certain vertical distance. It automatically compensates, offering high accuracy, good reliability, and simple installation and use.

Product SKU: Differential Pressure Density Meter - Insertion Type

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)