An oval gear flowmeter, also known as a displacement flowmeter, is a type of positive displacement flowmeter and offers the highest accuracy among flow instruments. It is particularly suitable for measuring the flow of highly viscous liquids such as heavy oil, asphalt, paint, diesel, and bunker fuel.

An oval gear flowmeter uses a mechanical measuring element to continuously divide the fluid into individual known volumes. The total flow volume is measured based on the number of times the metering chamber repeatedly fills and drains that volume.

Case Study

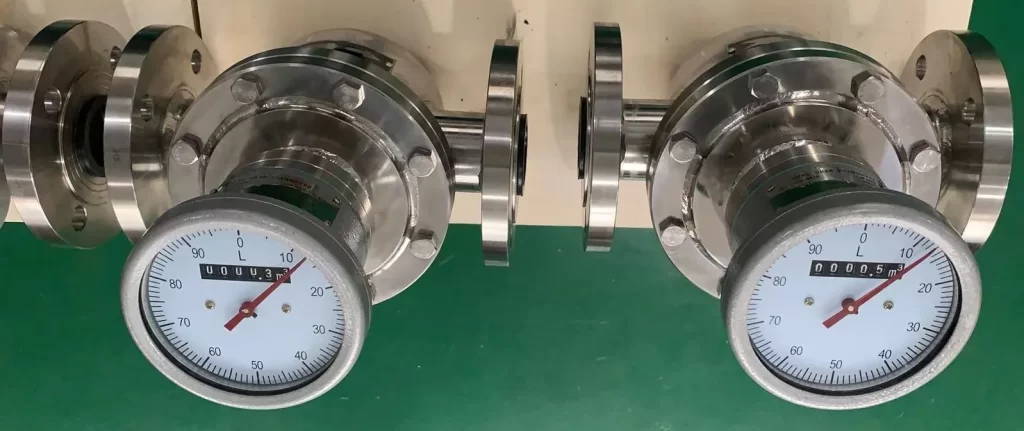

A customer from Malaysia wanted to measure the flow of paint used in electrostatic spraying. After discussion, we finally confirmed the following parameters:

- Oval gear flowmeter

- Flow range: 160-800 l/h

- Accuracy: 0.5%

- Medium: electrostatic coating (@2mPa.s)

- Maximum temperature: 80°C

- Connection: 25A JIS 10K FF flange (maximum pressure: 1.0MPa)

- 24VDC

- Relay switch signal

- Electronic meter head digital display

This customer requested a customized relay switch signal. For example, if the flow rate is set to 300 L/h, the switch will close when it reaches 300 L/h.

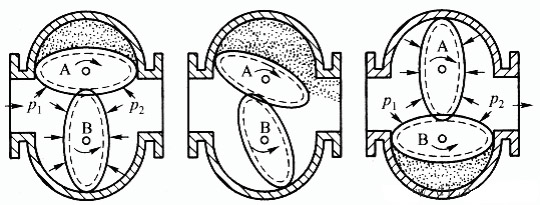

Measurement Principle

An oval gear flowmeter is a type of positive displacement flowmeter used for precise continuous or intermittent flow measurement or instantaneous flow of liquids in pipelines. It is particularly suitable for measuring the flow of high-viscosity media such as heavy oil, polyvinyl alcohol, and resin.

A flowmeter primarily consists of a housing, a counter, an oval gear, and couplings (magnetic and axial). An elliptical gear flowmeter consists of a metering box and a pair of elliptical gears mounted within it. These, along with the upper and lower covers, form a sealed, crescent-shaped cavity (not completely sealed due to the rotation of the gears), which serves as the unit of displacement. When the measured liquid enters the flowmeter through a pipeline, the pressure differential between the inlet and outlet drives the pair of gears to rotate continuously, continuously delivering the liquid measured by the crescent-shaped cavity to the outlet. The product of the number of revolutions of the elliptical gears and four times the displacement per time is the total flow rate of the measured liquid.

The higher the viscosity of the medium, the smaller the leakage through the gap between the gears and the metering cavity. Therefore, the higher the viscosity of the measured medium, the smaller the leakage error, which improves the measurement performance.

Advantages

- High measurement accuracy, wide flow range, and good repeatability;

- Uniform helical rotor rotation, low vibration, and long life;

- Insensitive to changes in the measured liquid’s viscosity, making it particularly suitable for measuring high-viscosity liquids;

- Simple structure and compact dimensions;

- Easy installation, requiring no straight pipe section before the meter;

- Customizable high-temperature models, up to 250°C;

- Customizable mechanical pointer display, no power required;

- Customizable intelligent digital display, supporting pulse, RS485, and 4-20mA signal outputs;

- Available in cast iron, cast steel, and all-stainless steel.

Applications Of Paint Flow Measurement

Automotive Manufacturing: A flow meter is installed at the front end of a robotic or manual spray gun. Based on real-time data on the instantaneous flow rate of the sprayed paint, the flowmeter adjusts the spray gun valve size to ensure uniform coating thickness on the body and components, effectively reducing material waste and rework.

Aerospace: Corrosion-resistant Coriolis flowmeters are used to accurately measure paint flow during the painting process on various areas of aircraft exteriors. These flowmeters are linked to the spray gun control system to adjust output at any time, ensuring that film thickness on curved surfaces and edges meets standards.

Continuous coating processes: A micro-flowmeter is installed at the die inlet, maintaining a real-time closed-loop relationship with an online thickness meter. This ensures consistent coating thickness in both the horizontal and vertical directions of films and foils, reducing raw material consumption.

Electrostatic spray systems: Equipped with a flowmeter for powder or liquid electrostatic spray guns, a PLC reads the flow rate in real time. Based on this flow rate reading, workers adjust the gun distance and voltage, improving the first-pass application rate and spraying efficiency while reducing downtime during color change.

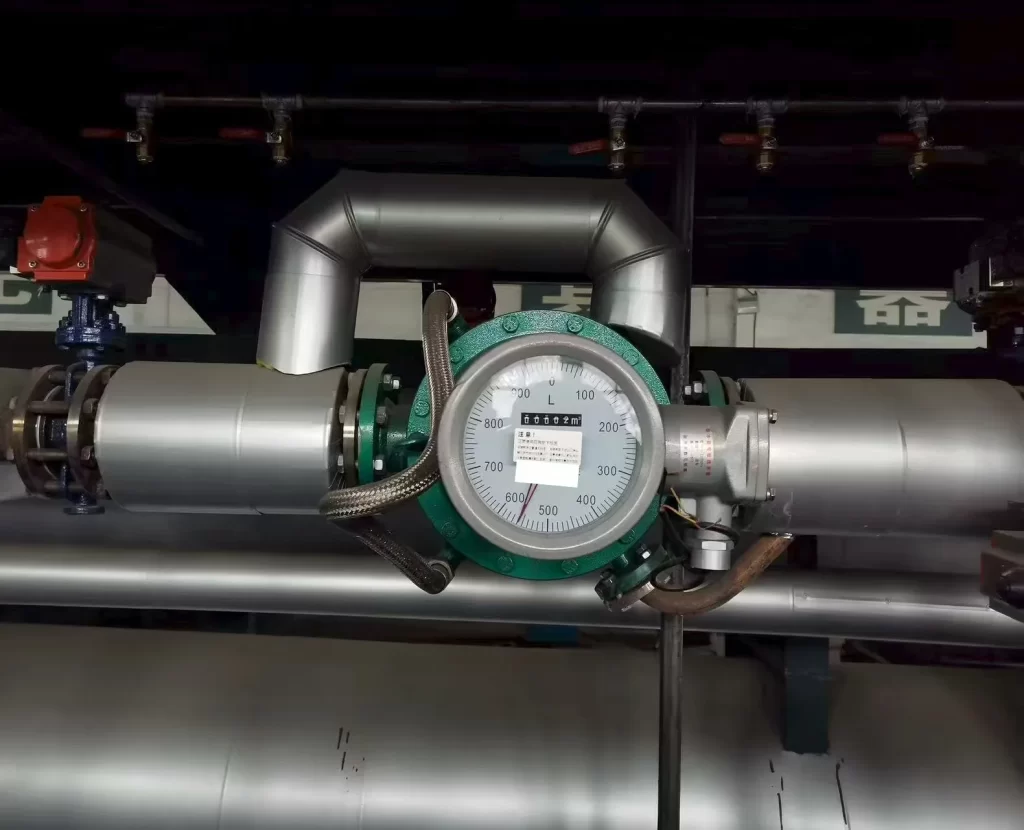

Paint Flowmeter Installation Precautions

Oval gear flowmeters should be cleaned before installation.

If the liquid contains solid particles, a filter must be installed upstream; if it contains gas, an exhaust device should be installed.

Oval gear flowmeters do not require any specific pipe lengths.

They can be installed horizontally or vertically. During installation, the oval gear axis of the flowmeter should be parallel to the ground. This installation minimizes gear friction, extends life, and improves accuracy.

Factors Affecting Oval Gear Flowmeter Accuracy

1. Oval gear flowmeters are suitable for measuring the flow of high-viscosity media, but not for fluids containing solid particles. Gas mixed in the measured liquid can also cause measurement errors.

2. If the flow rate of the measured medium is too low during use, the meter’s leakage error will become significant, and adequate measurement accuracy can no longer be guaranteed. Therefore, our oval gear flowmeters have a minimum operating flow rate limit. Measurement accuracy is guaranteed only when the actual measured flow rate exceeds this lower limit.

3. Furthermore, when using an oval gear flowmeter, it is important to ensure that the temperature of the measured medium does not rise too high. Therefore, oval gear flowmeters must be used within the specified operating temperature range.

4. Furthermore, after long-term use, the internal gears will corrode and wear, affecting measurement accuracy. Therefore, they should be carefully observed and regularly removed for inspection.

More Flowmeters Suitable For Measuring Paint Flow

1. Electromagnetic Flowmeters

Electromagnetic flowmeters measure flow only when the medium is electrically conductive. Generally, water-based paint can meet this requirement. Electromagnetic flowmeters can be customized with custom lining and electrode materials. They are wear-resistant, corrosion-resistant, and tolerant of particulate matter.

2. Circular Gear Flowmeter

Circular gear flowmeters are designed for low flow rates and high viscosity applications. Flow rates can be as low as 0.6 L/h, and high-pressure models up to 40 MPa are available. Using circular gear flowmeters requires the absence of impurities, so installing a filter is generally recommended.

3. Coriolis Mass Flowmeter

Coriolis mass flowmeters offer the highest accuracy, but they also come at a higher cost. They directly measure mass flow and are unaffected by fluctuations in viscosity and density.

More Solutions For Flow Measurement

- Slurry & Sludge Flow Measurement

- Case – Fluid Heat Measurement

- Variable Area Flow Meter Case: Oxygen Flow Measurement

- Annubar Flow Measurement: Principles, Applications, And Advantages

- More Convenient Flow Measurement-Battery Operated Flow Meters

- Opt The Right Flow Meter For Soy Sauce Flow Measurement

- Helical Flow Meters: Accurate Flow Measurement For Challenging Applications

- Calorimetric Flow Meter: An Economical Solution For Hot Water Flow Measurement

- Extreme Temperature Flow Meters: Accurate Flow Measurement In Harsh Environments

- The Next Level Of Flow Measurement: Here Come Non-Intrusive Flow Meters

- Flow Measurement For Powders And Granular Materials: Solid Flow Meter

- Rotameters: Excellent Choice for Flow Measurement in Various Gases

- High Accuracy Flow Meters: A Key To Precision In Flow Measurement

- Turbine Water Flow Meter: A Versatile And Reliable Choice For Water Flow MeasurementPulse Output Flow Meters for Better Water Flow Measurement

- Ultrasonic Clamp On Flow Meter – For Easier Water Flow Measurement

- Guide On Industrial Air Flow Measurement Devices

- Techniques, Importance, and Challenges of Natural Gas Flow Measurement

- DP Transmitter for Flow Measurement

- Approaches To Gas Flow Measurement: Types and Applications Of Gas Flow Meters

Summary

Sino-Inst’s oval gear flowmeters offer excellent performance and are suitable for a variety of media, including oils, chemical liquids, and food liquids. They can be customized for high temperatures and high viscosities. They can be customized with stainless steel, cast steel, and cast iron materials. They can also be customized with mechanical pointer displays or intelligent digital displays.

If you have any questions or concerns regarding flow measurement, please contact us and our professional technicians will be happy to answer your questions.

-1.jpg)