What is a torque sensor? A torque sensor is a device that measures the torque (torsion or rotational force) applied to a rotating shaft of a component or machine.

Torque sensors monitor and control the performance and condition of rotating components such as engines, motors, shafts, gears, pulleys, rollers, gears, and generators. They are widely used in the mechanical and industrial sectors, including manufacturing and R&D, particularly in the automotive and electric motor industries.

What is torque?

Torque is a key concept in physics that describes the magnitude of a rotational force. Its unit is Newton-meter.

Torque is simply the force that causes an object to rotate. For example, in a car engine, torque is key to generating horsepower and driving force, determining the vehicle’s acceleration and hill-climbing ability. In mechanical engineering, torque is related to the machine’s performance and power output. It is also closely related to the strength and durability of mechanical components; high torque can cause increased stress on mechanical components.

Torque is measured in Newton-meters, a composite unit composed of the newton, the unit of force, and the meter, the unit of distance.

Calculation Formula: In physics, the formula for calculating torque is T = F × d. T represents torque, F represents force, and d represents the distance traveled in the direction perpendicular to the force. This formula helps us quantify the strength of a rotational force.

Function of the torque sensor

Torque sensors are used to monitor torque on various rotating or non-rotating mechanical components. Some torque sensors can simultaneously monitor speed, power, angle, and other parameters.

Read more about: Industrial Applications of Torque Sensors

Types of Torque Sensors

Torque sensors can be categorized based on their operating principle, measurement method, and mounting method. Let’s take a closer look:

By Measurement Method: Dynamic Torque Sensors and Static Torque Sensors

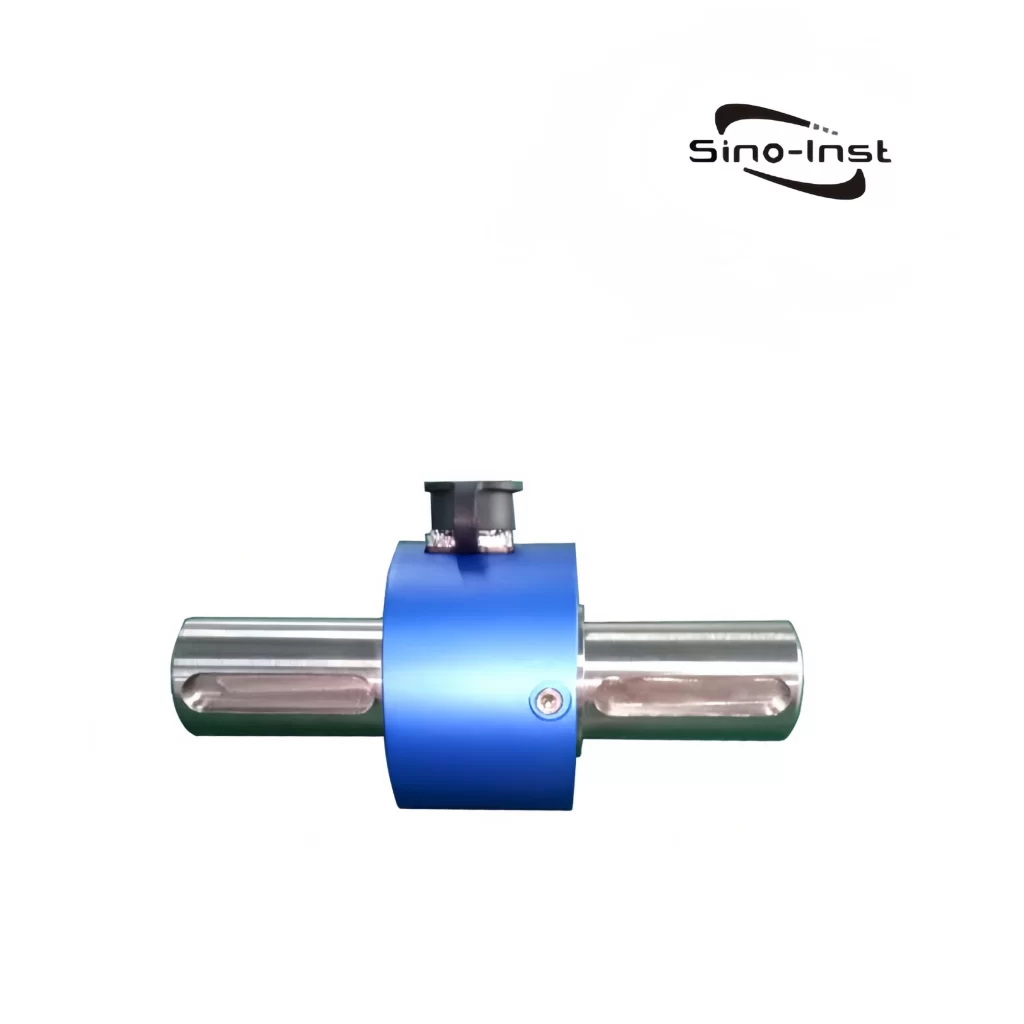

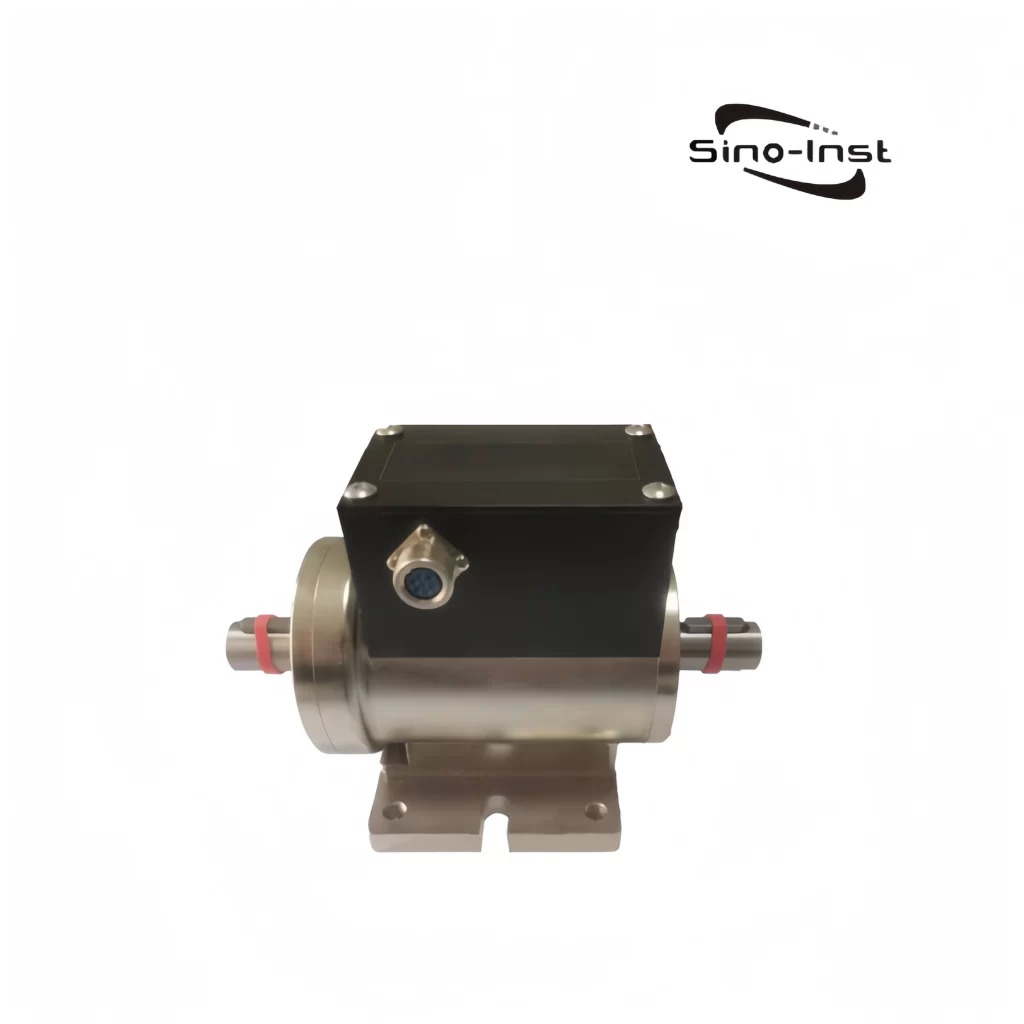

Dynamic torque sensors, also known as torque-speed sensors or non-contact torque sensors, are primarily used to measure the dynamic torque and speed of rotating objects. They typically consist of an induction coil, signal processing circuitry, and a magnet, and obtain torque and speed signals by measuring magnetic induction.

Static torque sensors are primarily used to measure static or steady-state torque, such as in door control systems or locking devices. These sensors typically consist of an elastic element and a measuring mechanism, and measure the torque value by measuring the deformation of the elastic element.

By Working Principle

Fiber optic torque sensors utilize optical fiber to transmit signals, offering high accuracy, high sensitivity, and strong anti-interference capabilities. Fiber optic torque sensors can measure minute torques down to micron-meters and are widely used in precision measurement and scientific research.

Resistive strain gauge torque sensors utilize a strain gauge as a sensitive element, converting torque into a change in resistance, which is then converted into an electrical signal through a measurement circuit. These sensors have a simple structure and high reliability, making them suitable for torque measurement in most mechanical transmission systems.

Inductive torque sensors utilize the magnetoresistance effect of magnetic materials to detect torque by measuring changes in the inductance of a coil. These sensors offer high accuracy, low inertia, and fast response speed, making them suitable for high-precision measurements and high-speed applications.

Hall-effect torque sensors utilize the Hall effect principle to obtain torque values by measuring changes in magnetic field strength. These sensors offer non-contact, high accuracy, and high speed, but require an external magnetic field generator.

Piezoelectric torque sensors utilize the piezoelectric effect to convert torque into electrical energy, measuring voltage or charge to obtain torque values. These sensors offer high sensitivity and high resolution, but require an external power supply.

By Mounting Method

Common torque sensor mounting methods include flanges, keys, and brackets.

Flange torque sensors can be categorized as single-flange and double-flange.

Single-flange torque sensors, as the name suggests, feature a flange on one end. This facilitates sensor installation and fixing, and the single-flange design is more convenient for field installation and use.

A double-flange torque sensor is a single-flange torque sensor with an additional flange structure, meaning both ends of the torque sensor have flanges.

Keyed connection: The input and output shafts are connected via a torsion bar. The input shaft has splines, and the output shaft has keyways. When the torsion bar is subjected to torque, the relative position of the splines and keyways changes, causing the magnetic induction of the splines to change. This change is converted into a voltage signal by a coil.

The shaft torque sensor can be connected to the object under test via a shaft to perform the actual measurement. For example, a base or side hole can be used to connect the housing to the test bench. During this process, precise alignment must be ensured so that the end of the measuring shaft is perfectly aligned with the drive and output shafts of the component under test. The measuring shaft can also be mounted in a suspended manner, supported by the drive and output shafts.

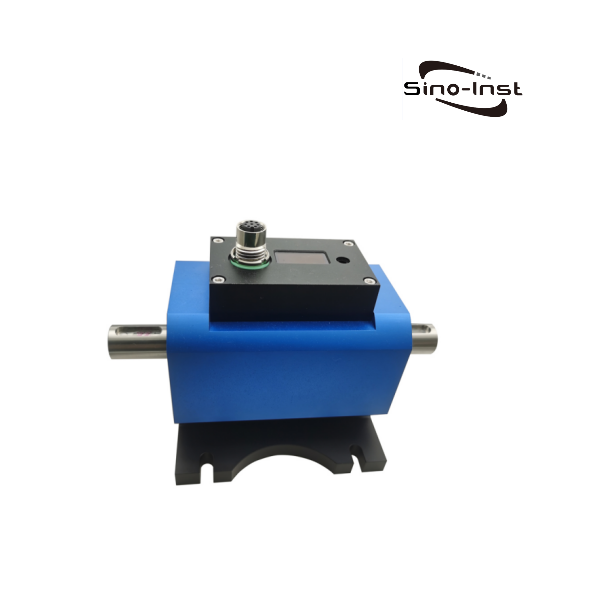

Featured Torques Sensors and Torque Measurement Solutions

Torque sensors are precision instruments used to measure various torques, speeds, and mechanical power. They are currently primarily used in the testing of rotating power equipment such as motors and engines. They are found in various industries, including manufacturing, transportation, and research institutes.

Sino-Inst supplies a wide range of torque sensors, meeting the accuracy, torque, and speed requirements of customers across various industries. If you require a torque sensor or have any technical questions, please feel free to contact us.

-1.jpg)