Gear Flow Meter technology is well proven and is the accepted technology for certain applications. It excels in measuring viscous media or media with lubricating properties. This media distinction helps to protect the gears.

Among the most accurate and skilled types of positive displacement (PD) flow meters are gear flow meters. They are accepted universally as the flow meter technology of choice due to the exact volumetric measurement.

This blog post dives deep into gear flow meters, focusing specifically on oval gear flow meters, spur gear flow meters, and helical gear flow meters.

Gear Flow Meter: The Definition

Gear flow meter is a type of volumetric flow meter (positive displacement flowmeters) that measures the flow of medium based on the rotation of gears. It is used for precise continuous or intermittent measurement of the flow rate or instantaneous flow rate of liquid in pipelines.

It is particularly suitable for the flow measurement of high viscosity media such as heavy oil, polyvinyl alcohol, resin, etc. But it is not suitable for fluids containing solid particles.

The types of gear meters are Oval Gear Flow Meters, Helical Gear Flow Meters, Spur Gear Flow Meters, and Screw Gear Flow Meters.

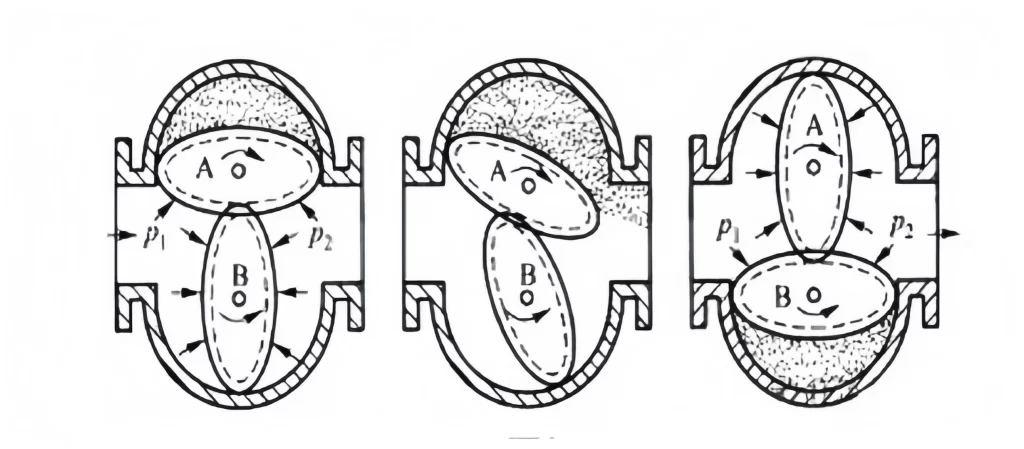

Gear Flow Meter is mainly composed of a metering chamber, a sealing mechanism, and a counting mechanism. The working principle is the positive displacement principle. The flow of the medium causes the gear to rotate, and the rotation of the gear is scanned by two non-contact pulse detectors. Each tooth generates a pulse. Finally, a frequency signal proportional to the flow rate is generated. Then the flow value Q is obtained.

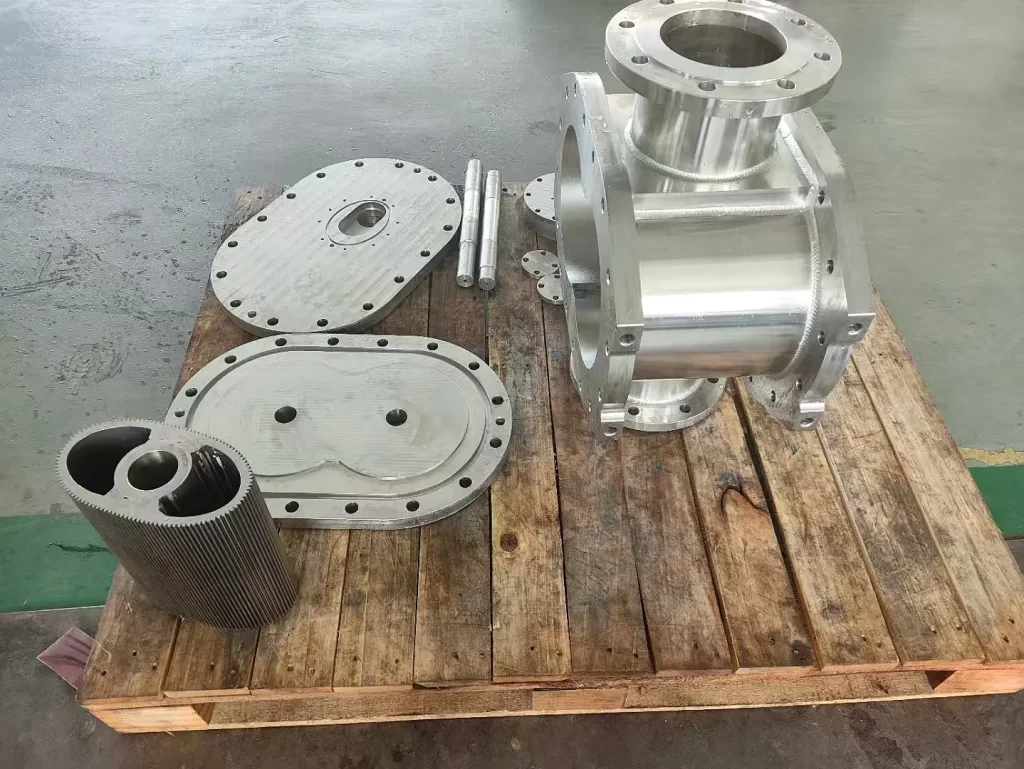

1. Measuring chamber:

The inner cavity of the instrument body and the cover plate constitute the measuring chamber. There are two shafts in the measuring chamber, and a pair of gears are sleeved on the shafts. It rotates due to the pressure difference between the inlet and outlet of the flowmeter. Thus, the liquid at the inlet is continuously metered through the crescent cavity and sent to the outlet.

Each rotation accumulates four times the volume of the crescent space. The gap between the gear and the inner wall of the measuring chamber is very small, only tens of microns, to reduce the leakage of the instrument.

2. Sealing mechanism:

The measuring chamber of the instrument is closed.

The small-diameter flowmeter adopts a permanent magnetic sealing mechanism. The active permanent magnet and the passive permanent magnet are separated by a partition. This structure has high sensitivity and reliable sealing.

The large-diameter flowmeter uses polytetrafluoroethylene plastic as a packing seal. The compression of the spring is changed by adjusting the nut. The sealing gasket is stretched to achieve the purpose of sealing. The structure is relatively simple and easy to adjust.

3. Counting mechanism:

The counting mechanism of the instrument includes a traditional gear train, a transmission ratio adjustment mechanism and a settlement mechanism.

The total number of rotations of a pair of gears and the speed of rotation are transmitted to the pointer and the character wheel of the settlement mechanism after the transmission gear train is changed. The total amount of liquid and the instantaneous flow rate through the pipeline can be known.

The transmission ratio adjustment mechanism is used to adjust and correct the instrument error.

The gear flowmeter is an electric pulse transmitter installed in the gear flow counting mechanism. That is, a disk with a permanent magnet is installed on the transmission shaft at the seal of the elliptical gear flowmeter, and a new magnetically sensitive integrated sensor is installed on the counter.

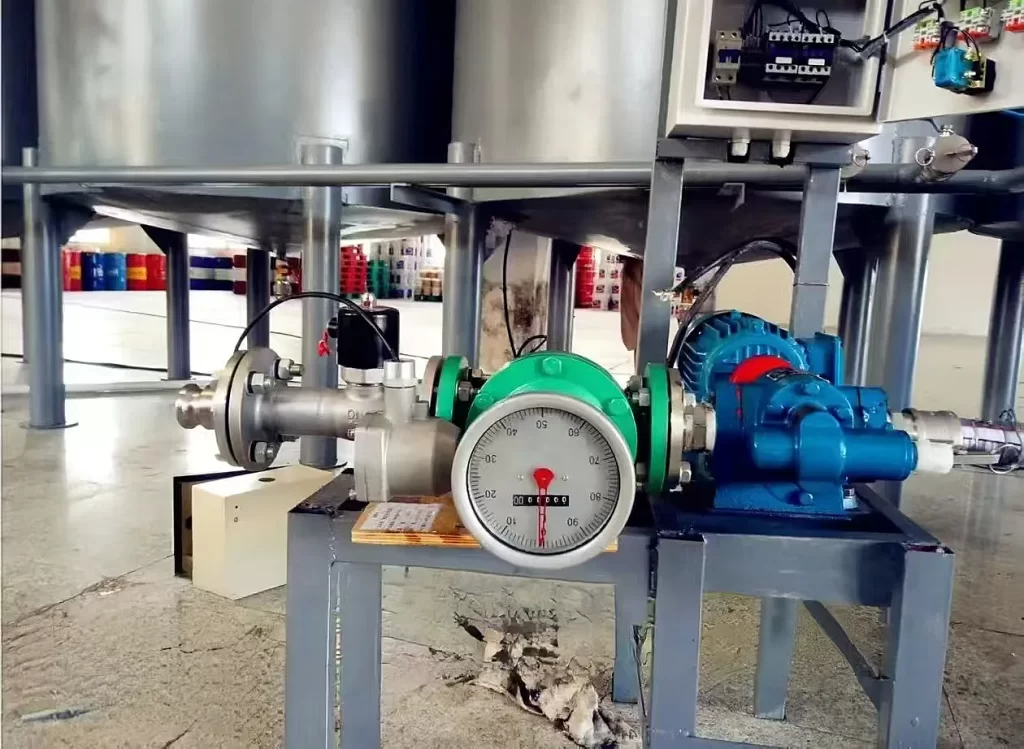

Gear flow meters from Sino-Inst

Sino-Inst offers High temperature and high pressure types gear flow meters for special use. With the features like: easy installation, high precision, and better price.

Spur gear flow meters can measure very small flows and quantify small volumes of liquid. Compared with oval gear flow meters, GF Series Gear Flow Meter has more advantages in measuring micro flow.

There are aluminum alloy, stainless steel material Spur gear flow meters from Sino-Inst. Hydraulic oil, diesel oil, and even high-viscosity fluids can be measured. There is a new type of PTFE material, which can withstand hydrofluoric acid, 98% sulfuric acid, nitric acid, hydrochloric acid, etc.

Gear Flow Meter Types

1. Oval Gear Flow Meters

Oval gear flow meters use two oval-shaped gears that rotate within a precisely machined chamber. These gears are positioned perpendicularly to each other and mesh together. As fluid enters the meter, it fills the chamber and forces the gears to rotate. Each rotation displaces a known volume of liquid.

A magnetic or optical sensor detects gear rotations and converts them into a flow rate or total volume reading.

Usages:

- Petroleum and fuel oils

- Chemical dosing

- Food-grade liquids like syrups and oils

- Paints and varnishes

- Pharmaceuticals

Benefits:

- High accuracy (up to ±0.1%)

- Not affected by viscosity changes

- Simple mechanical design with low maintenance

- No need for power supply in mechanical versions

- Can handle a wide range of flow rates

Limitations:

- Not ideal for abrasive or slurry fluids

- Pressure drop can be significant for high-viscosity fluids

- Sensitive to particulate contamination

2. Spur Gear Flow Meters

Spur gear flow meters operate similarly to oval gear meters but use a pair of spur (straight-toothed) gears instead of oval gears.

The fluid rotates two gears and is forced around the outside of the gears and the inside of the chamber. Depending upon the location of the sensor these can yield very high ‘pulses per litre’ values which are useful in batching and fast-acting processes.

Typically, a magnetic pickup detects gear rotation to provide flow readings.

Usages:

- Lubrication oil systems

- Hydraulic fluids

- Polymer additives

- Fuel measurement in automotive and aerospace

- Industrial chemical processes

Benefits:

- High-resolution measurement due to fine gear teeth

- Excellent for clean, low to medium viscosity fluids

- Compact design suitable for OEM integration

- Highly repeatable measurements

- High pressure 40MPa can be customized

- Suitable for low temperature -200℃, or high temperature 200℃

Limitations:

- Sensitive to fluid cleanliness – not suitable for fluids with particulates

- Wear and tear over time in aggressive environments

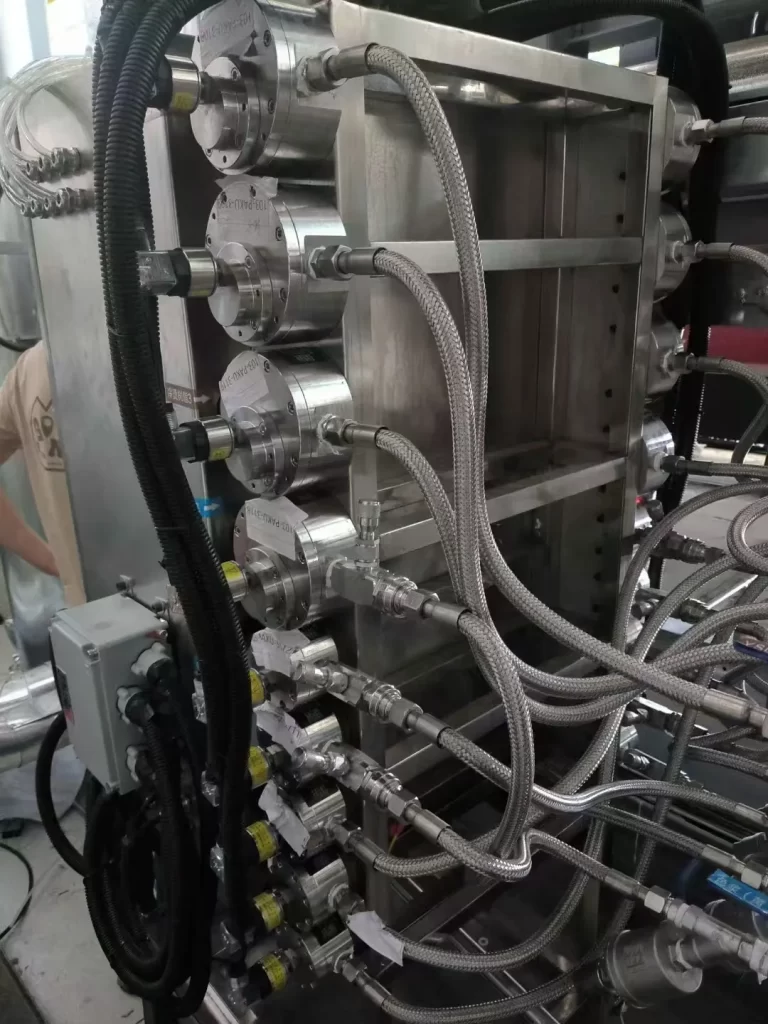

3. Helical Gear Flow Meters

Helical gear flow meters (also known as helical rotor flow meters) use two helical rotors that resemble intertwined screws. These rotors rotate in opposite directions within a precisely machined chamber. As the fluid flows through, it causes the rotors to turn, displacing a fixed volume of liquid.

This gear configuration allows for a very smooth and continuous flow, minimizing pulsations and improving accuracy in high-viscosity applications.

Usages:

- Asphalt and bitumen transfer

- Crude oil and refined oil products

- High-viscosity chemicals and resin

- Adhesives and sealants

- Molten waxes and polymers

Benefits:

- Outstanding for high-viscosity fluids (up to 1,000,000 cP)

- Smooth, low-pulsation flow measurement

- Excellent for high-pressure and high-temperature conditions

- Robust construction with high wear resistance

Limitations:

- Typically more expensive than other gear meters

- Larger footprint compared to spur and oval gear meters

- Requires more space for installation and maintenance

Key Considerations for Selecting a Gear Flow Meter

- Fluid Viscosity

- Low to medium viscosity: Spur or oval gear meters.

- High viscosity: Helical gear meters offer the best performance.

- Cleanliness of Fluid

- Gear meters generally require clean fluids.

- If the fluid contains particulates, a strainer or filter is essential.

- Flow Rate Range

- Oval gear meters offer a wide range.

- Spur gear meters are better suited for small, precise volumes.

- Helical gear meters handle high-volume, high-viscosity flows.

- Operating Conditions

- Helical gear meters perform best in extreme temperatures and pressures.

- Oval and spur gear meters are ideal for standard industrial conditions.

- Installation Environment

- Consider space constraints, maintenance accessibility, and integration with other systems.

More Flow Measurement Solutions

- More Convenient Flow Measurement-Battery Operated Flow Meters

- Complete Guide for Micro Motion Flow Meters

- Guide For Syrup Flow Meters

- Everything You Need To Know About Propane Gas Flow Meters

- Opt The Right Flow Meter For Soy Sauce Flow Measurement

- Dirty Water Flow Meters

- Potable Water Flow Meters In Domestic Water Supply Systems

- The Right Saltwater And Seawater Flow Meter For Your Needs

- Guide for Raw Water And Fresh Water Flow Meters

Two decades ago the PD meter was considered to be old technology and likely to be overtaken by ‘more modern’ electromagnetic and ultrasonic devices. In fact this has not happened because of the Gear flow meters categories. It still represents good value and can provide excellent measurement in a wide variety of duties.

Choosing the right type depends on your fluid properties, system requirements, and application constraints. With the right gear flow meter, you can achieve consistent and accurate flow measurement in even the most demanding environments.

Sino-Inst manufactures and supplies various types of gear flow meters, which are widely used in various industries in various countries. The United States, Singapore, Malaysia, Chile, etc. If you need to purchase, or have related technical questions, please feel free to contact us.

-1.jpg)