When configuring temperature sensors, you’ll encounter the option of whether to configure a thermocouple sheath, and the requirements for its size and material. Sometimes, a thermocouple sheath is also called a thermowell or temperature sensor protective tube.

So what exactly is a thermocouple sheath, and how do we choose one? Based on Sino-Inst’s experience, we’ve compiled this guide to help you understand thermocouple sheaths and select the appropriate one.

What is a Thermocouple Sheath?

A thermocouple sheath is a hollow tube, closed at one end and threaded or flanged at the other. It is permanently placed in pipes, tanks, or sump tanks so that a temperature measuring probe can be inserted into the hollow tube to measure the temperature of the contents. It also serves as a protective enclosure for the temperature sensor probe (RTD or thermocouple) from exposure to hazardous materials or harsh environments.

ASTM defines a thermocouple sheath as a closed, insertable tube used to house and secure a temperature-sensitive element to a container.

Thermocouple Sheath Working Principle

A thermocouple sheath acts as a barrier between the process medium and the temperature-measuring device sensor. This barrier protects the sensor from corrosive process media and pressurized or high-velocity fluids. The thermocouple sheath also maintains system integrity, allowing for easy removal of the temperature sensor from the system for maintenance.

Basic Structure of a Thermocouple Sheath

The basic structure of a conventional thermocouple sheath is shown in the diagram below:

- Bore Diameter (B): This is the inner diameter of the thermowell.

- Drill Depth (S): The total length of the bore.

- Insertion Length (U): The immersion length of the thermowell, often referred to as the “U” length, is the measurement from the bottom of the process connection to the top of the thermowell.

- Process Connection: This is the method by which the thermocouple thermowell is inserted into and connected to the process associated with the element connection. The most popular are threaded, socket weld, and flanged connections.

- Stem Structure: This is the immersion portion (stem) of the structure. Most fall into three categories: straight, stepped, or tapered.

- A straight stem has the same dimensions along its entire immersion length. For general purposes, a straight stem or rod is used when extra strength is not required.

- In some applications, a stepped stem has a larger outer diameter at the end of the immersion length to improve response time.

- The tapered version gradually decreases along the immersion length. Tapered thermowells are designed for high-velocity applications where extra strength is required. Special attention should be paid to vibration effects caused by fluid flowing through the thermowell.

- Lagging Extension Length (T): The lagging extension, often referred to as the “T” length, is located on the cold side of the process connection and is typically a hexagonal length extension.

- Base Diameter Size (Q): This is the external dimension of the thermowell stem, the densest part, as the outer surface area is exposed to harmful materials in the process.

- Tip Thickness (E): The thickness of the bottom of the thermowell.

- Tip Diameter (V): The diameter of the end of the thermowell.

Next, let’s look at the considerations when choosing a thermocouple sheath:

Types

Thermocouple sheaths are classified according to the design of the stem.

Straight thermocouple sheaths have the same diameter throughout the entire insertion length and provide corrosion and erosion protection.

Stepped thermocouple sheaths typically have a diameter of 3/4″ at the top and reduce to 1/2″ near the tip. The reduced surface area allows for smoother flow and faster temperature response of the sensing device.

Tapered thermocouple sheaths have a diameter that gradually decreases along the entire length of the insertion. They offer excellent strength and fast response to temperature changes. Tapered thermocouple sheaths are most commonly used in high-flow applications.

Materials

The choice of thermocouple sheath material depends on process conditions, such as the corrosiveness of the fluid being measured. For low-pressure and low-temperature applications, Teflon can be used to make thermocouple sheaths. Thermocouple sheaths can be made from a variety of materials, including brass, carbon steel (A105), stainless steel (SS304, SS304L, SS310, SS316, SS316L, SS446, SS410, SS317, SS317L, SS321), Monel, Hastelloy, Carpenter 20, Inconel, Incoloy, nickel, and titanium.

| Material | Temperature of use | Features and uses |

| 1Cr18Ni9Ti | -200~800℃ | Has high temperature corrosion resistance and is usually used as general heat-resistant steel; |

| 304 | -200~800℃ | Low carbon content, good intergranular corrosion resistance, usually used as general heat-resistant steel; |

| 316 | -200~750℃ | Low carbon content, good resistance to intergranular corrosion, used as corrosion-resistant steel; |

| 316L | -200~750℃ | Ultra-low carbon content, good resistance to intergranular corrosion, used as corrosion-resistant steel; |

| Monel | -100~700℃ | Nickel alloy has good intergranular corrosion resistance and is suitable for use in corrosion-resistant occasions such as strong sulfuric acid; |

| Hastelly C-276 | -100~700℃ | It has excellent intergranular corrosion resistance and is used as corrosion-resistant steel; |

| Inconel600 | -100~1000℃ | Nickel-chromium iron alloy has excellent high-temperature oxidation resistance and is usually used as heat-resistant steel; |

| 310S | -200~1000℃ | It has high temperature oxidation resistance and corrosion resistance, and is usually used as heat-resistant steel; |

| GH3030 | 0~1100℃ | Nickel-based high-temperature alloy steel has excellent oxidation resistance and corrosion resistance, and is usually used as heat-resistant steel; |

| GH3039 | 0~1300℃ | Nickel-based high-temperature alloy steel has excellent oxidation resistance and corrosion resistance, and is usually used as heat-resistant steel; |

| High alumina | 0~1300℃ | Industrial ceramic pipe, with excellent oxidation resistance and corrosion resistance; |

| Corundum | 0~1600℃ | Industrial ceramic pipe, with excellent oxidation resistance and corrosion resistance; |

| 3YC52 | 0~1300℃ | High-temperature alloy, with excellent oxidation resistance, corrosion resistance, mechanical properties, and suitable for high-temperature places; |

| Molybdenum disilicide | 0~1600℃ | It has excellent oxidation resistance, corrosion resistance, good mechanical properties, and is suitable for high temperature places; |

| PTFE | -150~+300℃ | It is resistant to corrosion by almost all organic solutions. Generally used as corrosion-resistant pipe; |

| Note: For other materials,please consult customer service! | ||

Mounting Methods and Dimensions

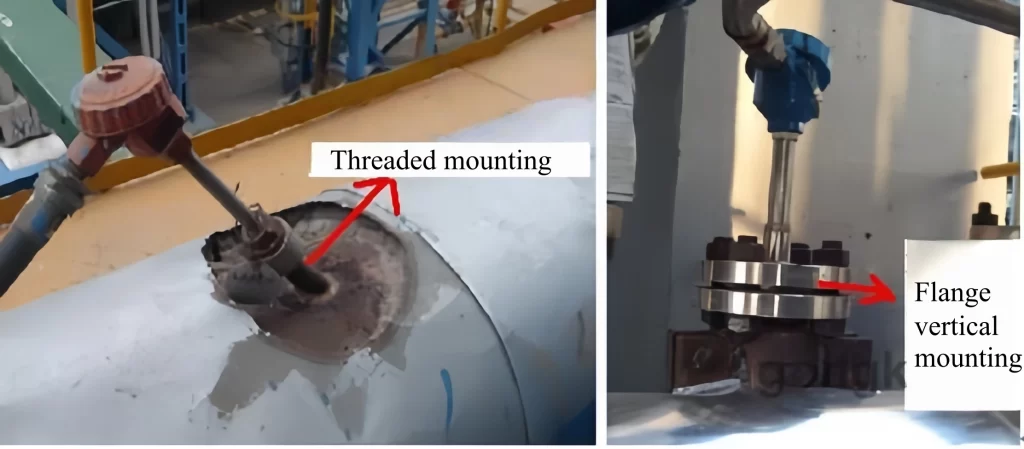

Threaded Thermowells:

These are used in smaller pipes to measure the temperature of non-corrosive fluids, with the thermocouple sheath screwed into the pipe.

Flanged Thermowells:

Flanged thermocouple temperature sensor sheaths are connected to the pipe using nuts and bolts at the flange end. The thermowell has a flange collar that connects to the mating flange. This type of thermocouple sheath is used when frequent replacement or removal is required.

Flanged thermowells are used in high-temperature applications.

Welded Thermowells:

Welded thermowells are welded directly into the pipe. Because the thermowell is welded into the pipe, it is used for permanent connections.

Probe Length

The temperature sensor tip should be in contact with the bottom of the thermocouple sheath. A temperature sensor (such as a thermometer, thermocouple, or resistance temperature detector) is placed in the open end of the thermowell, usually spring-loaded to ensure metal-to-metal contact between the outer tip of the temperature sensor and the inner tip of the thermowell. Since air acts as an insulator, the fit of the sensor should be as tight as possible to minimize the annular gap.

Currently, there is no standard method for selecting probe length based on the thermocouple type. Different standards specify different thermocouple probe lengths, and the dimensions of sensor probes such as thermometers, RTDs, and thermocouples also vary. The appropriate probe length should be selected based on the temperature sensor.

To achieve the highest possible accuracy, it is recommended that the insertion length be long enough to allow the entire temperature-sensitive portion of the measuring device to extend into the medium being measured.

When using a temperature sensor to measure liquid temperature, the device should extend into the solution. The length of the temperature-sensitive portion should be extended by at least one inch. For gases or air, it should be immersed to the length of the temperature-sensitive section plus 3 inches.

The temperature-sensitive portion of a thermocouple or thermistor is short; therefore, a thermowell with a shorter insertion length can be used. The temperature-sensitive parts of bimetallic thermometers, RTDs, and liquid-in-glass thermometers are between 1″ and 2″ in length and must be immersed in the liquid for at least 2½” to achieve acceptable accuracy.

Probe Diameter

The casing diameter should be appropriately selected based on the pressure rating. For medium and low-pressure applications, casing diameters of 25-19mm (large end to small end) can be used. For high-pressure applications, casing diameters of 32-21mm (large end to small end) can be used.

Manufacturing Process

Thermocouple and resistance thermometer casings are manufactured using two processes: one is welded steel pipe, and the other is integral drilling.

The welded steel pipe type has one end sealed, and the casing generally has a thin wall and a large inner diameter, thus resulting in low pressure resistance, only up to 6.4 MPa. If the casing is installed on a pipeline, even with low operating pressure, the casing may fracture and be damaged due to vibration caused by the high fluid velocity.

The integral drilling type is formed by drilling a solid rod. The casing has a small inner diameter and a tight fit with the measuring element, resulting in fast response speed, good vibration resistance, and high pressure resistance, reaching over 30 MPa.

More Temperature Measurement Solutions

Temperature sensors are rarely placed directly within industrial processes. They are typically housed in thermocouple sheaths to isolate them from potentially harmful process conditions such as fluid tension, high pressure, and corrosive chemicals. With thermocouple sheaths, sensors can be quickly and easily removed from the process environment for calibration and replacement without stopping the process or draining the process medium from piping and containers.

Choosing the right thermocouple sheath is both difficult and challenging. You may need to consider the details of both the temperature sensor and the thermocouple sheath during the design phase. If you still have questions about thermocouple sheath selection after reading this guide, please feel free to contact us.

-1.jpg)