The Universal Intelligent Capacitive Level Transmitter is a liquid /material level transmitter suitable for measuring liquids, oils, solids, and interfaces. It is unaffected by water vapor, dust, or condensation. It offers long-term stable and reliable operation and is resistant to high temperatures and high pressures.

This intelligent capacitive level transmitter uses a two-wire (loop-powered) 4-20mA/D converter with 485 transmission. It is widely used in various fields, including petroleum, chemical, metallurgy, power generation, papermaking, and pharmaceuticals.

Features

- The simple structure, with no moving or elastic components, ensures high reliability and minimal maintenance.

- Multiple signal outputs facilitate diverse system configurations.

- Suitable for level measurement in high-temperature and high-pressure vessels. The measured value is unaffected by the temperature, specific gravity, shape, or pressure of the measured liquid.

- Particularly suitable for measuring highly corrosive liquids such as acids and alkalis.

- Fully protected against overcurrent, overvoltage, and power polarity errors.

- Compatible with any conductive medium.

Technical Data

| Attributes | Parameters |

| Detection range | 0.1-30m |

| Capacitance measurement range | 0.1PF-2500PF |

| Accuracy | 0.2% FS/0.5% FS |

| Pressure range | -0.1MPa-32MPa |

| Probe temperature resistance | -50-550°C |

| Ambient temperature | -40-85°C |

| Storage temperature | -50°C-+60°C |

| Output signal | 4-20mA, 4-20mA superimposed HART communication, 485 communication, etc. |

| Wireless output type | Communication distance less than 200m |

| Supply voltage | Power supply voltage 4.2-36V (battery power optional) |

| Level sensor material | 15-36V DC |

| Long-term stability | 316 stainless steel, 1Gr18Ni19Ti, or polytetrafluoroethylene |

| Temperature drift | ≤0.1% FS/year |

| Explosion-proof rating | ≤0.01% FS/°C (within 0-70°C range) |

| Protection level | Ex iaIIC T6 Ga |

| Intrinsically safe parameters | IP67 |

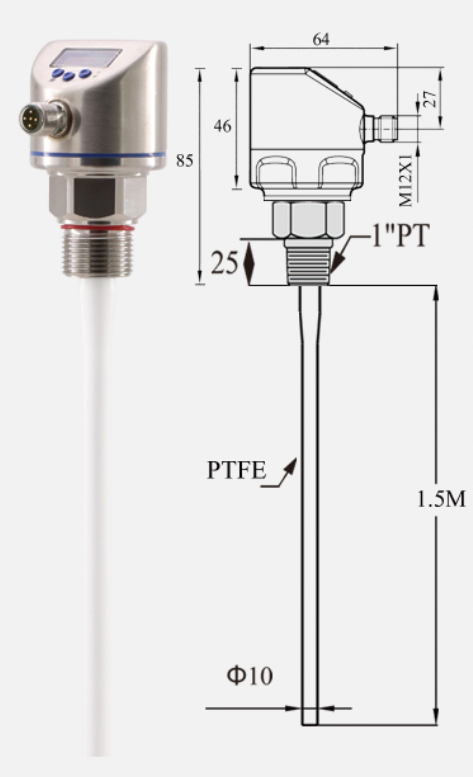

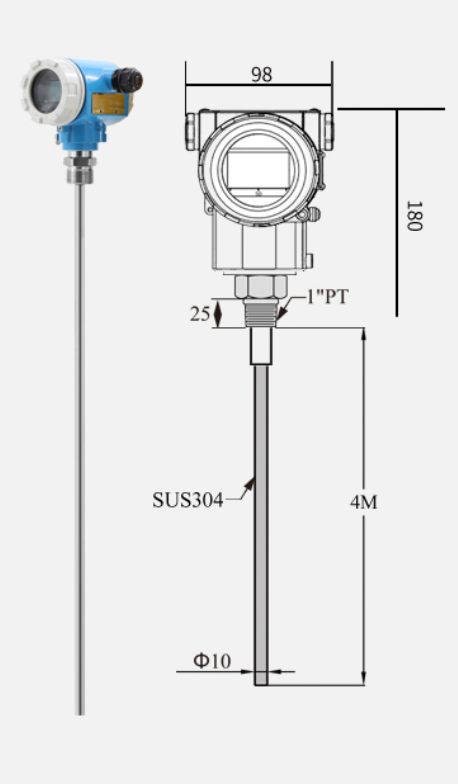

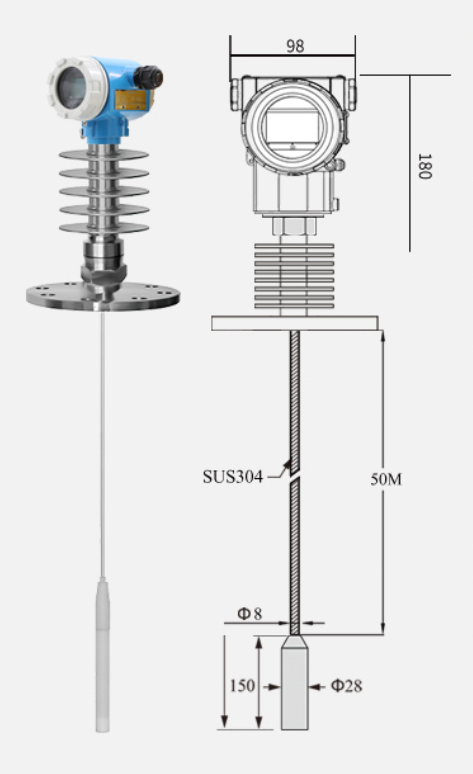

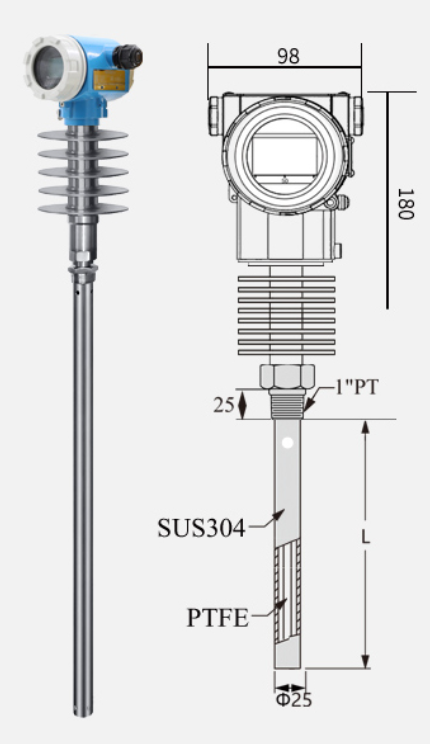

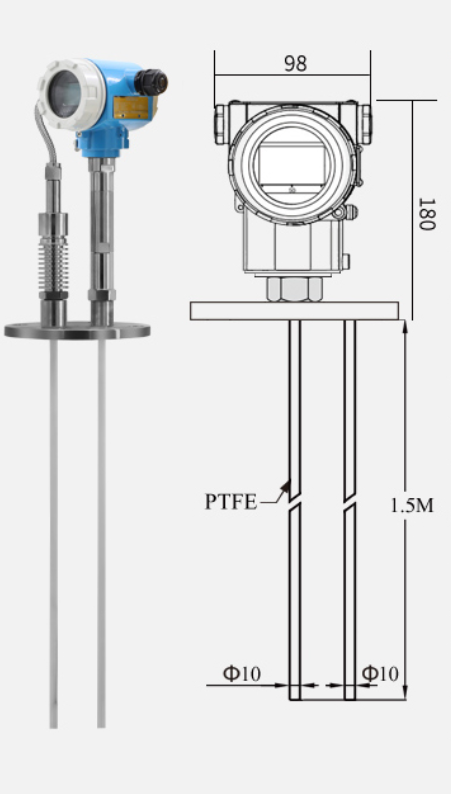

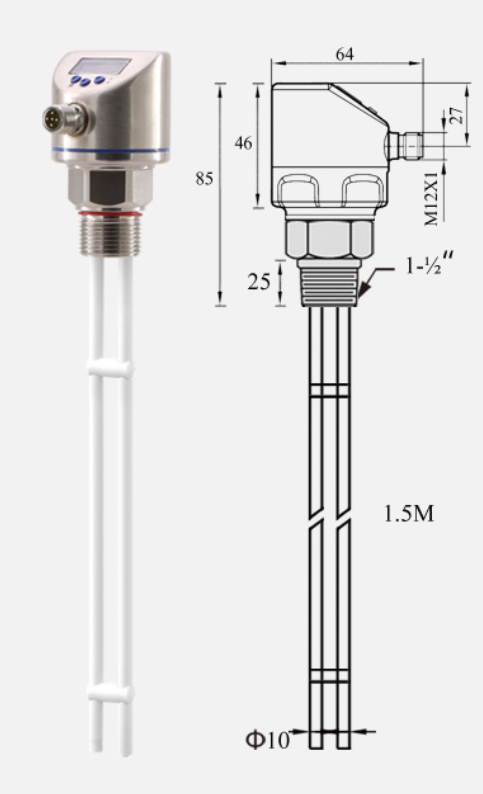

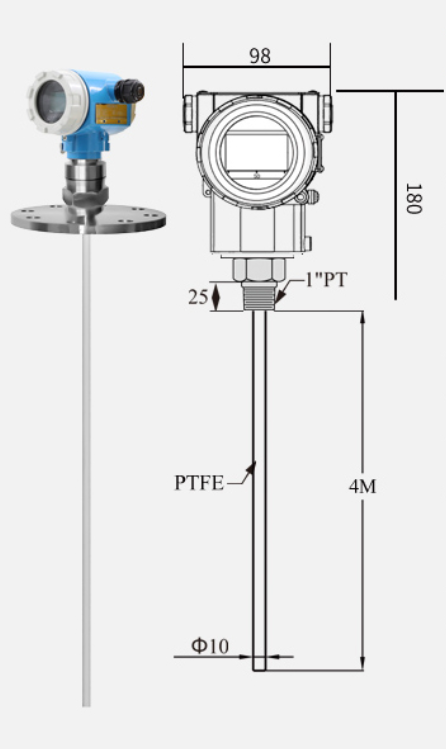

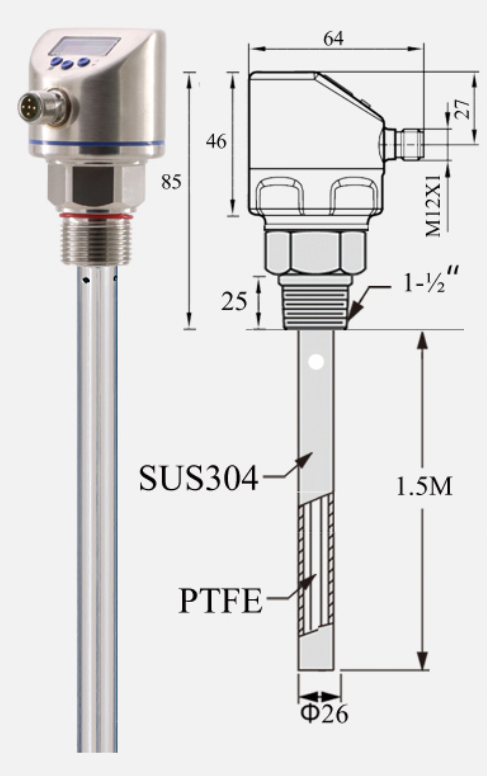

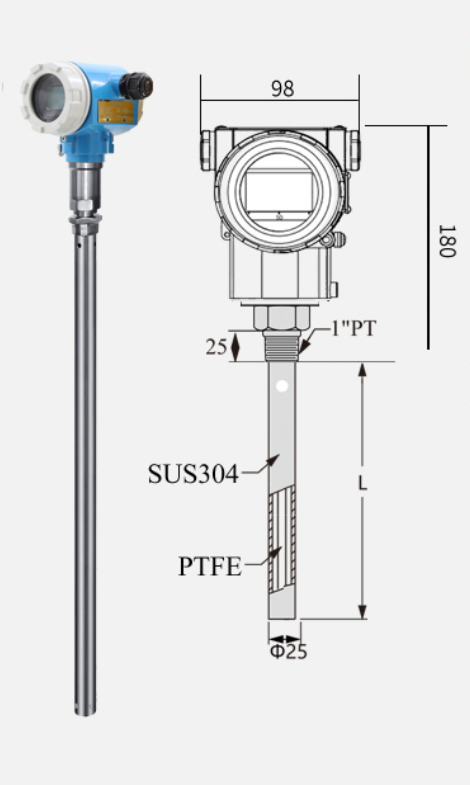

Capacitive Level Transmitter Structure

The structure of a capacitive level transmitter varies depending on the application and parameters. However, its main structure can be roughly divided into two parts: the sensor and the transmitter. As shown in the figure:

Figure A shows the sensor, which is inserted directly into the measured medium in the container or measuring tube.

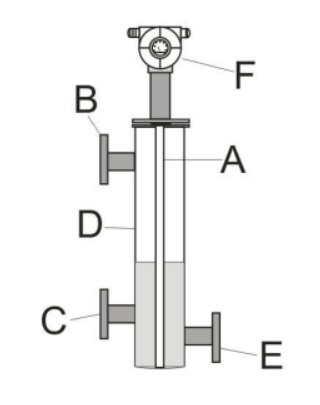

A capacitive level transmitter generally consists of a sensor, a transmitter, and other auxiliary equipment. A typical application uses the connecting tube principle to introduce the medium from the device under test into the measuring tube. The sensor is located in the center of the measuring tube. The inflow of liquid or changes in the interface cause a change in the dielectric constant between the sensor’s electrodes and the inner wall of the measuring tube, resulting in a change in capacitance.

The sensor then detects this capacitance change and transmits it to the transmitter, which converts it into a 4-20mA signal output. The measured medium level in the measuring tube is then equivalent to the level of the medium in the device, thus enabling measurement of the medium within the device.

In the figure, B and C show the gas and liquid connection flanges of the liquid level transmitter, respectively. They are used for connecting equipment flanges and directing the liquid and pressure inside the equipment to the measuring cylinder.

D in the figure shows the measuring cylinder of the Capacitive Level Transmitter, which forms a capacitance with the sensor electrodes.

E in the figure shows the drain flange, which regularly drains contaminants from the liquid level transmitter. Keep the measuring cylinder clean to prevent contaminants from sticking to the sensor.

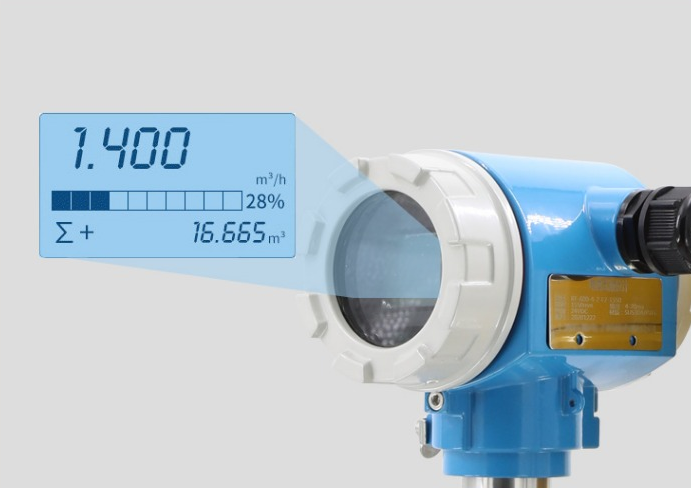

F in the figure shows the transmitter, which converts capacitance into a standard current signal. It is the central component of the entire liquid level transmitter. Its primary function is to receive the incremental capacitance change caused by liquid level fluctuations sent by the sensor. It then converts the capacitance into a 4-20mA current signal.

This Capacitive Level Transmitter features low power consumption, high temperature resistance, strong reliability, and intrinsically safe compliance. Its fully sealed housing is specially corrosion-resistant and can be used in explosion-proof and corrosion-resistant industrial and mining environments.

Note: There is a sealed section between the transmitter and the measuring cylinder. This section is composed of several sealing components, which can ensure that the measured medium contacts the sensor but does not leak out and cause harm. This section is an important sealing part. Do not dismantle it without the manufacturer’s consent to avoid accidents.

How Do Capacitive Level Sensors Work?

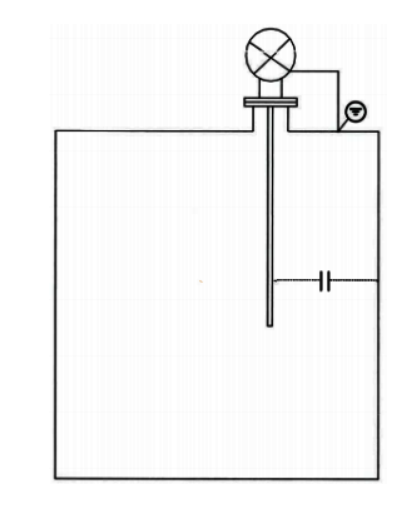

A capacitive level transmitter consists of a measuring electrode, a preamplifier unit, and a receiving unit. An equivalent capacitance is formed between the electrode and the container. By measuring the capacitance change due to liquid level fluctuations, the liquid level within the container can be determined.

The capacitance of the measuring electrode is C0 + ΔC. C is the capacitance of the empty tank after the electrode is installed, and ΔC is the capacitance change due to liquid level fluctuations. The diagram shows the principle of a capacitive level sensor.

For limit switch measurement, the capacitance change ΔC between the probe in contact with the medium and the probe not in contact with the medium is measured. The circuit converts ΔC into ΔU and simultaneously drives the switch output.

Capacitive Level Sensor Types

① Depending on the measurement requirements, they can be divided into continuous capacitance level sensors and switching capacitance level sensors.

② Depending on the insulation type, they can be divided into fully insulated and semi-insulated types.

Capacitive Level Sensor Disadvantages

- If the measured medium is a conductive, viscous medium, a layer of the measured medium may still adhere to the electrode sleeve when the liquid level drops, causing false level indications. In this case, the probe should be cleaned regularly.

- Use with viscous or easily sticky media should be avoided.

- Because the level sensor is directly mounted on the equipment and lacks a root valve, it cannot be disassembled online.

- For non-conductive media, recalibration is required when the dielectric constant changes.

- Compared to level sensors based on other principles, such as radar, guided wave radar, and ultrasonic sensors, capacitive level sensors have lower accuracy.

Capacitive Level Transmitter Applications

- Continuous Level Detection

- Limit level detection for viscous liquids or slurries.

- General level detection (water/water-based media/oil, etc.).

- Interface Detection (continuous/switchable)

- Oil-water interface detection.

- Limit Switch Detection

- Limit level detection for viscous liquids or slurries.

- Foam detection for conductive liquids. General point level detection (various solids/liquids).

- Two-point pump control.

More Level Measurement Solutions

Sino-Inst’s capacitive level transmitters can measure the level of highly corrosive media, high-temperature media, and sealed containers. They are widely used in level measurement and management of liquids, oils, and solid materials.

Our capacitive level transmitters are customizable, including rigid rod probes, rope probes, and dual-electrode probes. If you require level measurement, please feel free to contact our engineers!

-1.jpg)