A thermal diffusion flow switch is a flow monitoring device based on the principle of thermal diffusion. It offers superior performance and reliability. Thermal diffusion flow switches have no moving parts. They are durable, have low maintenance costs, and are highly reliable.

We, Sino-inst, offer the SI-300C and SI-600 series of thermal diffusion flow switches. They can output PNP, NPN, relay, and normally open + normally closed (SPDT) signals. This article will provide a detailed overview of thermal diffusion flow switches.

What is thermal dispersion?

Thermal diffusion is a technique for measuring fluid flow rate using heat transfer. Its principle is based on the cooling effect of the measuring fluid on a heated sensor. The thermal diffusion principle is commonly used in airflow and HVAC systems, industrial processes, flow switches, and controllers.

The heated sensor element transfers heat to the fluid. The amount of heat loss is proportional to the fluid’s mass flow rate. We can measure the temperature difference between the heated sensor and a reference sensor. This allows us to calculate the fluid’s velocity or mass flow rate.

What is a thermal dispersion flow switch?

Thermal flow switches and thermal diffusion flow switches refer to the same technology. They both operate on the principle of “thermal diffusion.”

A thermal flow switch is a device used to monitor and control the flow rate of liquids in pipelines. A thermal diffusion flow switch is a specific type of thermal flow switch. Essentially, all thermal diffusion flow switches are thermal flow switches. However, not all thermal flow switches are thermal diffusion type.

Thermal diffusion flow switches detect the flow rate of liquids or gases using the principle of thermal diffusion. Thermal flow switches typically feature no moving parts, require no maintenance, and have a compact structure. They are widely used in industries such as petrochemicals, power generation, and metallurgy.

The difference between thermal mass flow meters and thermal flow switches

Thermal mass flow meters and thermal flow switches operate on similar principles, but they are not the same.

A thermal mass flow meter provides continuous, real-time measurement of mass flow rate. A thermal flow switch is a simple on/off device. It only triggers an alarm or action when the flow rate exceeds a preset threshold.

| Feature | Thermal Mass Flow Meter | Thermal Flow Switch |

| Function | Continuously and accurately measure mass flow rate. | Detect and signal when the flow rate exceeds a preset threshold. |

| Output | Provides continuous output signals. | Provides simple on/off signals or digital signals. |

| Complexity | More complex. Thermal mass flow meters need to calculate the flow rate based on the thermodynamic properties of the fluid. | Simpler. Thermal flow switches only need to determine whether specific conditions are met. |

| Measurement Capability | It can accurately measure flow rate within a certain range even at extremely low flow rates. | It does not measure flow rate; it only indicates whether the flow rate is higher or lower than the set value. |

| Application | Real-time process control, monitoring, and data acquisition requiring precise flow rates. | Simple alarm systems, pump protection, or triggering of process start/stop. |

Thermal flow switch working principle

A heat flow switch works by measuring the cooling effect of a flowing fluid on a heated probe. It typically uses two temperature sensors:

one is a heating sensor, and the other is a reference sensor. The heating element inside the heating sensor is usually a platinum resistance thermometer (RTD) or a thermistor. Their temperature is higher than the fluid temperature. The reference sensor only measures the temperature of the surrounding fluid.

When fluid flows, the heating sensor cools down. A temperature difference develops between the two sensors. The higher the flow rate, the stronger the cooling effect, resulting in a smaller temperature difference. When this temperature difference reaches a preset value, the relay is triggered to open or close the circuit.

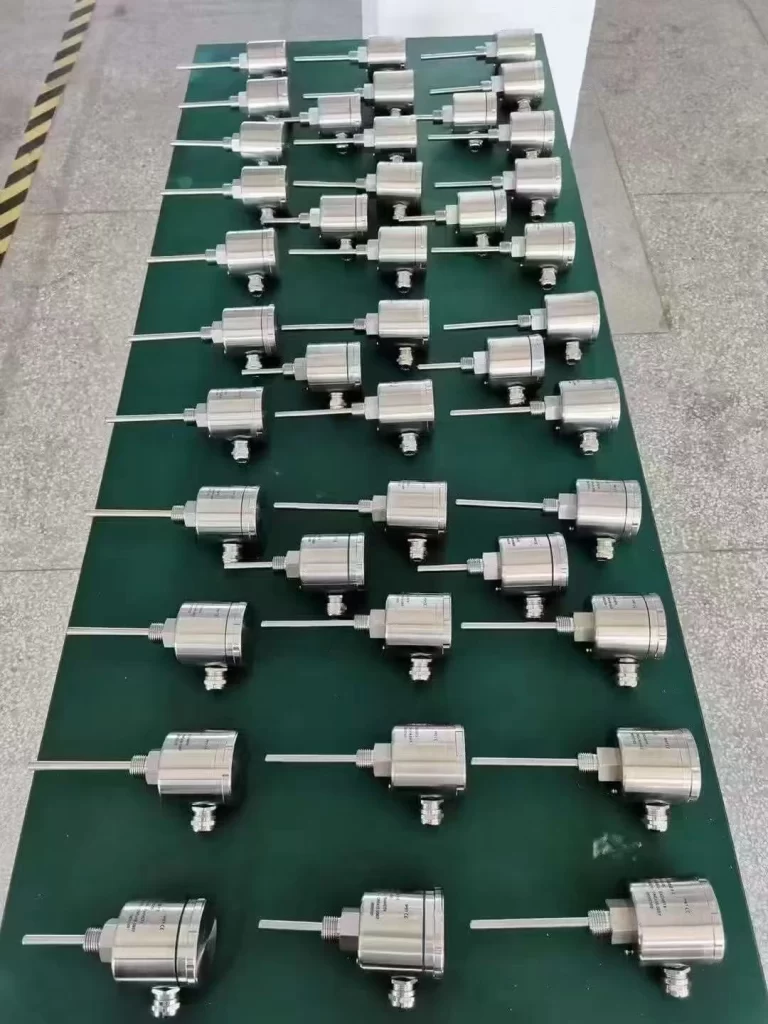

Common thermal dispersion flow switch

SI-300C Thermal Dispersion Flow Switch

The SI-300C thermal dispersion flow switch operates on the principle of thermal dispersion. It detects changes in flow rate by measuring the rate at which heat dissipates from the fluid.

Its enclosed probe contains two resistors. One acts as the sensing resistor, heated to function as the sensing resistor. The other serves as a reference resistor and is not heated.

When the medium flows, heat is dissipated from the heated resistor, causing a change in resistance. The difference between the two resistors is the basis for determining the flow rate.

Features

- The SI-300C thermal diffusion flow switch has no moving parts, making it easy to install.

- One model can meet the requirements of various pipe diameters.

- The switching value is continuously adjustable.

- Extremely low pressure loss.

- Compact design.

- An LED display shows the flow trend and switching status.

SI-600 Thermal Dispersion Flow Switch

The SI-600 thermal diffusion flow switch also monitors fluid flow rate in pipelines based on thermal principles. It can output PNP, NPN, relay, and normally open + normally closed (SPDT) signals. Suitable for media such as water, oil, and air.

Thermal diffusion flow switches are widely used in petrochemical, food processing, and water treatment applications. They can also be employed in pneumatic and hydraulic systems, circulating water systems, and for dry-running protection of pumps.

Features

- Unique conical probe design effectively prevents flow loss caused by entanglement in the medium.

- Fully waterproof housing design. Unique waterproof adjustment knob. Adjustable without removing the sealing screws, convenient and reliable.

- Suitable for various pipe diameters, adjustable setpoint, and corrosion-resistant type optional.

- Pressure resistance up to 100 Bar.

- Six LED indicators display fluid flow status in real time.

Thermal dispersion flow switches for liquids

Thermal diffusion flow switches utilize the heat dissipation of a sensor to detect liquid flow rate. They have no moving parts and are durable. Suitable for a wide variety of liquids, even those containing impurities.

In practical applications, a sensor is heated, and the flow of the liquid cools it. As the flow rate increases, the temperature difference between the heated sensor and the reference sensor decreases. This is then electronically converted into a signal to trigger a relay or alarm.

Use of Thermal Dispersion Flow Switches for Pump Protection

Operating a pump with insufficient liquid flow can lead to excessive wear, component damage, and even shutdown. This increases the costs of replacing parts, repair labor, and lost production.

Many technologies can be applied to pump protection. You can use a flow meter, but flow meters are generally more expensive than flow switches. Mechanical flow switches are another option. We typically choose thermal diffusion flow switches.

Thermal diffusion flow switches protect pumps by detecting low flow conditions when the pump is running dry. This method is highly adaptable to a wide variety of fluids, robust, and can also be used to detect high flow conditions in some applications.

Advantages of thermal dispersion flow switch

Thermal diffusion flow switches offer numerous advantages. They are versatile and suitable for a wide range of liquids and gases, including corrosive and hazardous substances.

Thermal diffusion flow switches deliver precise performance and are highly sensitive to low flow rates. With no moving parts, they offer extended service life and require minimal maintenance.

Thermal dispersion flow switches offer flexible installation, accommodating both horizontal and vertical mounting. They are not restricted by flow direction or alignment. Requiring only a short insertion length into the fluid, they cause minimal pressure drop. Installation remains straightforward even in complex locations or confined spaces.

FAQ

More Flow Measurement Solutions

Powder/Dry Material Level Switches – Product List and Selection

Powder/Dry Material Level Switches are devices used to detect when material reaches a preset level. When the material reaches or exceeds the set position, the level switch sends a signal, typically used to control the starting or stopping of equipment. They are widely used in silos, hoppers, storage tanks, and other locations for simple on/off … Read more

Rotameters: Excellent Choice for Flow Measurement in Various Gases

A rotameter, also known as a variable area flow meter, is widely used to measure the flow rate of various gases, especially in situations where no power supply is available. Whether measuring air, oxygen, nitrogen, carbon dioxide (CO2), or other gases, rotameters provide reliable and accurate results. Of course, rotameters can also be configured as … Read more

Flow Meter Selection Guide: Starting from Measurement Conditions

There are more than a dozen categories and hundreds of models of flow meters on the market, all claiming to have unique measurement advantages. So how do you choose the flow meter that meets your needs? Simply put, start with your actual measurement conditions. Select the most suitable flow meter based on your specific application … Read more

4 Types of Manifolds for Pressure Transmitters

Pressure transmitters are often installed in conjunction with manifolds, primarily for isolation, calibration, and venting. Manifolds control the input of the medium, ensuring measurement accuracy and safety. Manifolds are typically configured with a specified number of valves based on the required operating conditions. Common configurations include single-valve (2-valve), two-valve, three-valve, and five-valve manifolds. When purchasing … Read more

Industrial Water Pressure Measurement and Monitoring

Water pressure measurement includes pressure detection of water pipes, water containers or equipment. Water pressure measurements can be used to determine whether a pipe, container or equipment is leaking and whether it can withstand the pressure required for the design. By configuring a water pressure transmitter, connecting the water pressure signal to a recorder, PLC … Read more

Choose Digital Water Pressure Switch for Better Control

A water pressure switch is a device used to monitor and control the pressure of a water system. Commonly found in domestic and industrial water treatment systems, it is used to start or stop water pumps and ensure that the water pressure remains within a set range. A digital water pressure switch can display the … Read more

Thermal dispersion flow switches are widely used in industrial environments. Sensor designs vary according to specific application scenarios, including commonly used spherical probes, low-flow probes, and high-temperature/high-pressure probes.

Sino-Inst thermal diffusion flow switches are suitable for various media and operating conditions. Furthermore, this switch supports multiple output signal options, such as PNP, NPN, and relays. You can choose according to your specific needs.

If you need to purchase a flow switch or have any related questions, please feel free to contact our sales engineers.

-1.jpg)