Soy sauce is probably man’s oldest prepared seasoning. Soy sauce is a dark-brown liquid extracted from the fermented mixture of soybeans and wheat. Due to its salty taste and sharp flavor, it is served as an all-purpose seasoning for thousands of years.

Due to the attributes such as high viscosity, salt content, and potential for foaming, a special approach is required to ensure accurate and reliable flow measurement of Soy Sauce. In this blog post, we explore the key considerations in selecting a soy sauce flow meter and the available technologies.

Challenges in Measuring Soy Sauce Flow

Viscosity Variability: Depending on temperature and formulation, soy sauce viscosity can vary, affecting flow behavior.

High Salt Content: Corrosive properties demand robust, corrosion-resistant materials.

Foaming and Bubbles: Aeration during processing can introduce air bubbles, leading to inaccurate readings.

Sanitary Requirements: Food processing standards require meters that comply with hygiene and clean-in-place (CIP) protocols.

Kinds of Flow Meters for Soy Sauce Measurement

To address these challenges, several flow meter technologies are commonly used in the Soy Sauce industry:

Electromagnetic Flow Meters (Magmeters):

Benefits for its use in measuring Soy Sauce Flow:

- Excellent for conductive liquids like soy sauce.

- No moving parts, reducing maintenance needs.

- Resistant to corrosion, making it a durable choice for salt-rich liquids.

Sino-Inst Sanitary Magnetic Flow Meter with Tri-Clamp Connection is a very much suitable flowmeter for soy sauce.

Salient features:

- It adopts sanitary lining materials and clamp connection processing technology, which meets the hygiene requirements of the food industry.

- Stainless steel shell and stainless steel clamp connection are convenient and quick to disassemble and clean.

- High-definition backlit LCD display. Easy to use, simple to operate, easy to learn and understand.

- With RS485, RS232, Hart, and Modbus digital communication signal output.

- The intelligent converter can simultaneously display volume flow percentage, instantaneous flow, cumulative flow, and other measurement data;

- Accuracy: class 0.5 or 0.2, Diameter: DN10~DN100 (mm), Flow rate range: 0.3~10m/s.

Positive Displacement (PD) Meters:

Benefits for it’s use in measuring Soy Sauce Flow:

- Suitable for high-viscosity liquids, ensuring precision even with variable flow rates.

- Requires regular maintenance but provides reliable volumetric measurement.

Digital gear flow meters are commonly used for measuring Soy Sauce Flow. It is a kind of positive displacement flowmeter, and it is a kind of high-precision flowmeter.

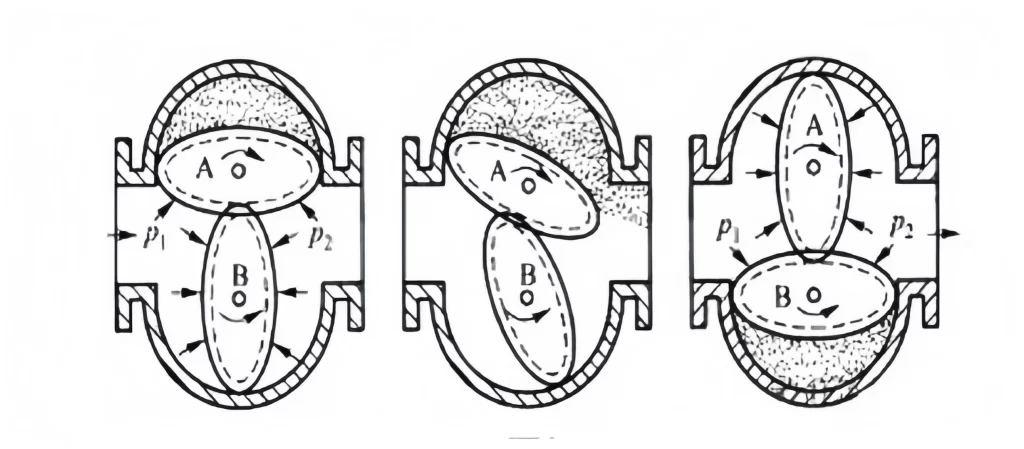

It uses a mechanical measuring element to continuously divide the fluid into a known volume portion. It measures the total flow rate based on the number of consecutive fillings and discharges of the volume portion of fluid in the metering chamber.

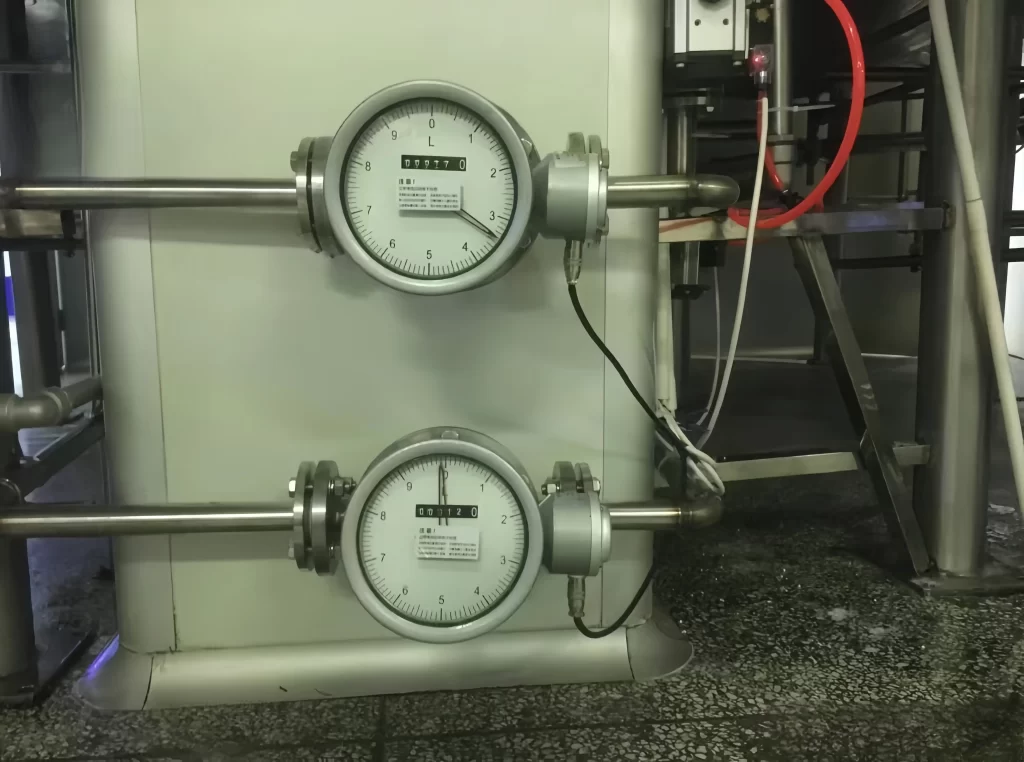

The oval gear flowmeter in the picture can be made of different materials (plastic, cast iron, cast steel,304 stainless steel, 316 stainless steel). It is suitable for flow measurement in the food industry.

Salient features:

- Ideal for low flows and flow measurements involving starts and stops or pulses.

- Instead of the gears driving the fluid, the fluid drives the gears.

- No direct upstream and downstream piping is required during installation.

- Specifically designed for accurate measurement of thicker fluids.

- High measurement accuracy: 0.2 and 0.5;

- The mechanism is simple, sturdy and reliable.

- The traditional positive displacement flowmeter uses a pointer indication and does not require a power supply; an electronic display can be added to support customization of pulse, 4-20mA, RS485 and other signal outputs.

- Easy to install. There is no need for straight pipe sections before and after the flowmeter, and there is no need to install straight pipe sections.

- In order to prevent the gear of the flowmeter from being jammed by impurities, a filter must be installed upstream of the flowmeter.

- Explosion-proof grade: ExiaIICT6.

Key Factors in Choosing a Soy Sauce Flow Meter

- Accuracy Requirements: High-precision meters like Coriolis and magmeters are preferred for quality control.

- Material Compatibility: Stainless steel and food-grade coatings prevent corrosion and contamination.

- Cleaning and Maintenance: Hygienic design with CIP compatibility ensures compliance with food safety regulations.

- Cost and Installation Considerations: While Coriolis meters offer top-tier accuracy, mag meters and ultrasonic meters may provide a more cost-effective solution.

More Flow Measurement Solutions

- Dirty Water Flow Meters

- Potable Water Flow Meters In Domestic Water Supply Systems

- The Right Saltwater And Seawater Flow Meter For Your Needs

- Guide for Raw Water And Fresh Water Flow Meters

- Electromagnetic Interference Resistant Flow Meters

- Helical Flow Meters: Accurate Flow Measurement For Challenging Applications

- Bitumen And Asphalt Level Meters: Let’s Learn More About Them

- Rotary Flow Meters for More Stable Measurement and Control Systems

- Fertilizer Flow Monitoring: Liquid Fertilizer Flow Meters

Selecting the right flow meter for soy sauce measurement depends on balancing accuracy, durability, and cost. By understanding the unique demands of soy sauce flow measurement, manufacturers can optimize their production processes, ensuring quality and efficiency.

Sino-Inst is a Professional flowmeter manufacturer and supplier from China. Sino-Instrument sells through a mature distribution network, that reaches all 50 states and 30 countries worldwide. Flow meter products are most popular in Domestic Market, Southeast Asia, Europe,and America.

-1.jpg)