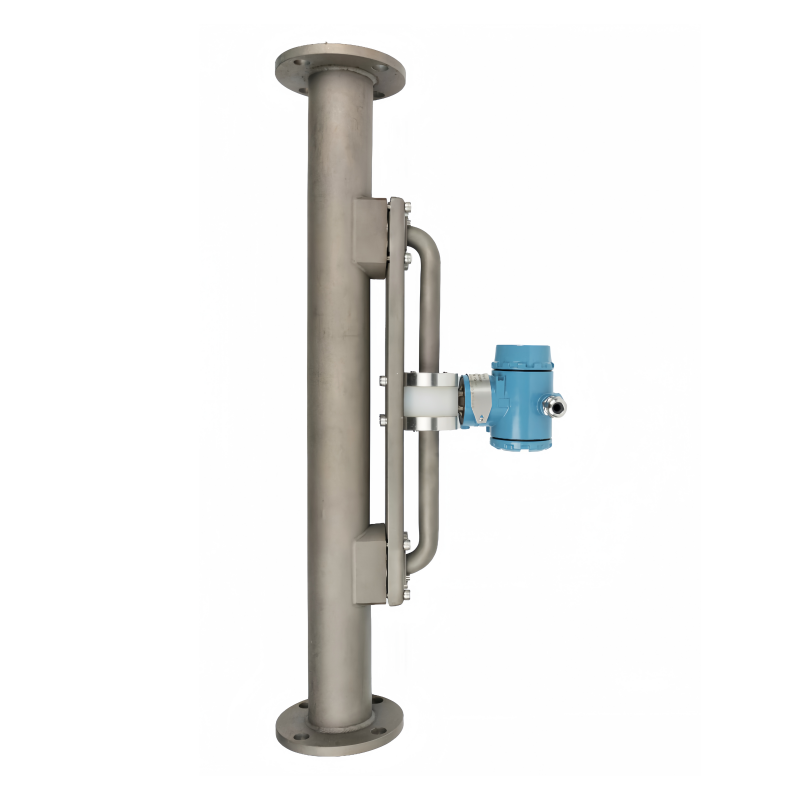

The Pipe Type Inline Density Meter is an instrument that can monitor the density of media in pipelines in real time. It can be installed directly on the pipeline or on a bypass pipe to perform online density measurements on various liquids or liquid mixtures.

Features

Technical Specifications

| Output Signal: | Two-wire 4-20mA, superimposed with Hart protocol digital signal |

| Power Supply: | 12-36VDC |

| Density Range: | 0-5g/cm³ |

| Accuracy: | 0.005g/cm³ |

| Electrical Interface: | M20×1.5 |

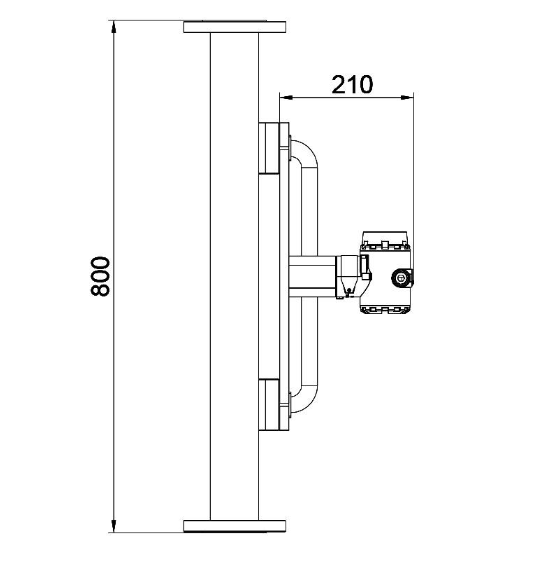

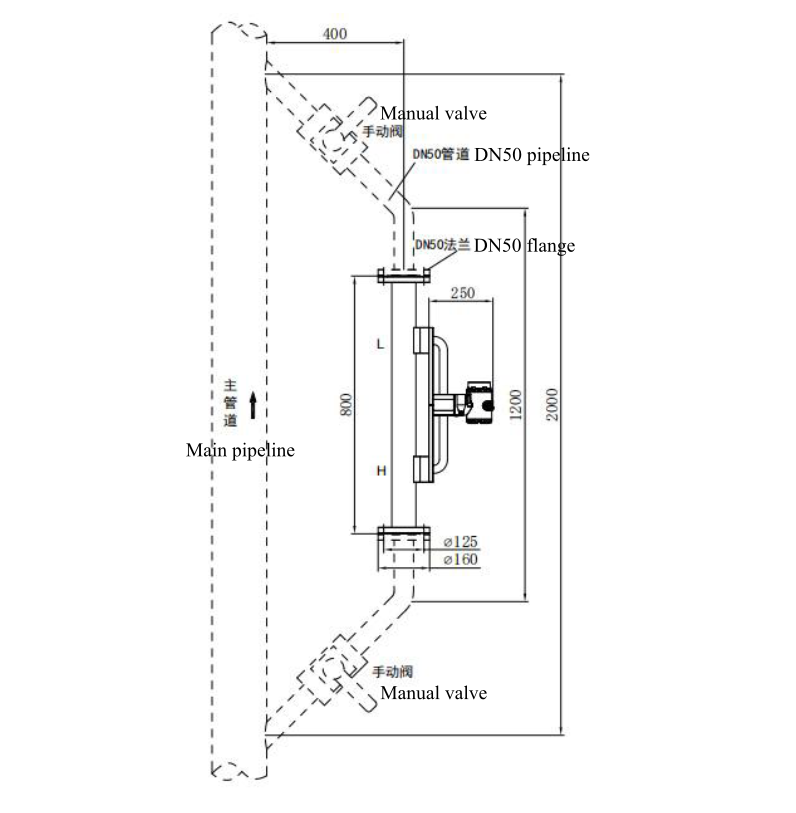

| Process Interface: | Various flange specifications |

| Wetted Parts: | 316 stainless steel or corrosion-resistant materials |

| Filling fluid: | DC200 silicone oil (olive oil for sanitary type) |

| Explosion-Proof Type: | Flameproof, intrinsically safe |

| Permissible Temperature: | -20 ~ 300°C |

| Operating Voltage: | 12 ~ 45 VDC |

Liquid Density Measurement

Measuring liquid density can identify the composition, purity, and concentration of a liquid, and can also assist in confirming the mass flow rate of the liquid. This information enables engineers and technicians to make informed decisions in research, manufacturing, and quality assurance.

Measuring liquid density is important across various industries.

- In chemical laboratories, accurate density measurements are essential for determining material properties, identifying unknown compounds, and ensuring the quality of chemical products.

- In the pharmaceutical industry, density measurements aid in drug formulation, assessing stability, and ensuring consistent dosages.

- In the food and beverage sector, density measurements are critical for quality control, ensuring proper sugar content in beverages, determining fat content in dairy products, and evaluating additive concentrations.

- In oil and gas exploration, density measurements aid in characterizing rock formations, determining crude oil composition, and assessing the potential for extracting natural resources.

- Environmental scientists rely on density measurements to monitor water pollution levels, evaluate the health of aquatic ecosystems, and detect hazardous substances.

Types of Inline Density Meters

Industrial online density meters primarily include: tuning fork vibrating density meters, differential pressure density meters, Coriolis density meters, optical density meters, and float density meters.

Tuning Fork Vibrating Density Meter: When an object vibrates upon excitation, its vibration frequency or amplitude relates to the object’s intrinsic mass. If a specific volume of liquid sample is introduced into the object, changes in its vibration frequency or amplitude reflect the mass or density of that sample volume.

Differential Pressure Density Meter: Based on the principle of pressure difference and hydrostatic pressure (P=ρgh), the sensor features two pressure-sensitive diaphragms with a fixed distance between them. Density is measured by detecting the pressure difference across these diaphragms.

Coriolis Density Meter: The measuring tube of the Coriolis force online density meter continuously vibrates at a specific resonance frequency. Since the resonance frequency is functionally related to fluid density, filling the vibrating tube with fluids of different densities alters its vibration frequency. Therefore, measuring the frequency change of the vibrating tube completes the density measurement, where density exhibits a unique linear relationship with the vibration frequency. This method offers precise and reliable measurements with a wide adaptability range for various fluid densities. The Kori density meter exhibits minimal pressure loss, providing inherent advantages for measuring viscous fluids like slurries.

Optical Concentration Meter: This device utilizes the propagation laws of light spectra within liquids. High-resolution spectral sensors collect samples, which are then analyzed and processed by software to identify concentration patterns. After temperature compensation, it measures the concentration of various liquids or liquid mixtures. The liquid must possess sufficient transparency. It finds extensive application in the petrochemical industry for testing petroleum, refining, and blending operations.

Float-Type Density Meters: The buoyancy force exerted on an object within a fluid is proportional to the fluid’s density—greater density yields greater buoyancy. If the sample temperature is standardized (e.g., 25°C), the instrument can also display specific gravity values as scale readings. The simplest variant is the visual float-type glass hydrometer, commonly referred to as a glass hydrometer.

Inline Density Meter Selection Guide

Choosing the right inline density meter requires comprehensive consideration of the actual media parameters and installation scenario. We suggest you follow these steps:

- Identify the medium being measured.

- Density measurement range.

- Medium temperature and pressure.

- Medium chemical properties, such as whether it is corrosive.

- Installation location: on the tank or on the pipeline?

- Installation type and dimensions, e.g., DN50 flange.

- Are there any restrictions on installation space?

- Power supply requirements.

- Signal output, such as 4-20mA, HART, RS485, etc.

- Special requirements, such as explosion-proof.

More Inline Density Meters

Differential pressure pipe-type inline density meters are used for online density measurement of various liquids or liquid mixtures. They are field instruments for continuous online measurement of liquid density and can be directly used in industrial production processes.

Sino-Inst manufactures and supplies various types of liquid inline density meters. Customization of parameters such as pressure, temperature, material, and size is supported. If you need density measurement, please feel free to contact our engineers!

Pipe Type Inline Density Meter - Sino-Inst

The Pipe Type Inline Density Meter is an instrument that can monitor the density of media in pipelines in real time. It can be installed directly on the pipeline or on a bypass pipe to perform online density measurements on various liquids or liquid mixtures.

Product SKU: Pipe Type Inline Density Meter

Product Brand: Sino-Inst

Product In-Stock: InStock

5

-1.jpg)