Magnetic type flow meters are based on the Faraday principle of electromagnetic induction and are used to measure the flow of liquids with conductivity greater than 5µS/cm. The split design is suitable for high-temperature, outdoor, or special environments. The sensor is submersible. The transmitter meets explosion-proof requirements.

This split-mount smart flow transmitter displays instantaneous and accumulated flow rates, and outputs pulse and analog current signals for fluid flow measurement and control.

| Diameter | DN6~DN2200mm |

| Accuracy | 0.5% ~ 2.0% of reading |

| Temp. range | <60℃ |

| Flow rate | 0.3~10m/s |

| Electrode | 316,HastalloyB(HB),HastalloyC(HC), Titanium(Ti),Tantalum(Ta),Platinum(Pt) |

| Protection proof | IP67, IP68(suitable for remote type) |

Magnetic Type Flow Meter Features

Specifications

| RS485, GPRS,Hart | |

| Medium | Acid, alkali, salt and other corrosive medium in chemical industry |

| Diameter | DN6~DN2200mm |

| Accuracy | ±0.5% |

| Medium temperature | <60℃ |

| Nominal pressure | GB 0.6MPa (DN700~DN2200) |

| GB 1.0MPa (DN200~DN600) | |

| GB 1.6MPa (DN6~DN150) | |

| DIN PN16,PN25,PN40,PN63 | |

| JIS10K,20K,40K | |

| ANSI Class150,Class300,Class600, others can be customized | |

| Flow rate | 0.3~10m/s |

| Straight pipe required | Upstream ≥5DN,downstream ≥3DN |

| Electrode | HastalloyB(HB),HastalloyC(HC),Titanium(Ti),Tantalum(Ta),Platinum(Pt), |

| Tungsten carbide(WC) (For acid and alkali salt solution) | |

| Installation way | Carbon steel flange (standard), Stainless steel flange(optional) |

| Body material | Carbon steel (standard),Stainless steel(optional) |

| Power supply | 220VAC/24VDC/lithium battery |

| Signal output | Pulse and 4~20mA;(if use lithium battery, without signal output) |

| Communication | Carbon steel (standard), Stainless steel(optional) |

| Explosion-proof | No |

| Protection proof | IP65(compact type),IP67,IP68(suitable for remote type) |

| Work environment | Ambient temperature:-20~+60℃,Ambient humidity:5%~90% |

| Power | <20W |

Electrode material selection:

| Sodium hydroxide, ammonium hydroxide alkali solution and weak organic acid | Medium |

| 316L | Domestic water, industrial water, raw water, urban sewage, etc. |

| Hastelloy B (HB) | 1. Salt solution (chloride, sodium salt, potassium salt, ammonium salt, sea water, etc.)2. Alkaline solution (such as a concentration less than 50% potassium hydroxide solution) |

| Hastelloy C (HC) | Oxidizing salt solution (Fe+++, Cu++, seawater) |

| Titanium (Ti) | 1. Salt solution (chloride, sodium salt, potassium salt, ammonium salt, sea water, etc.)2. Alkaline solution (such as concentration less than 50% potassium hydroxide solution) |

| Tantalum(Ta) | 1. Hydrochloric acid, sulfuric acid, oxidizing acid, aqua regia 2. Chlorine dioxide, ferric chloride, hypochlorous acid, sodium cyanide, lead acetate, etc. |

| Platinum (Pt) | Acid, alkali, salt solution |

| Tungsten carbide (WC) | Handled neutral industrial sewage and domestic sewage. Resistant to solid particle interference |

Lining material selection

| Lining material | Linner | Temperature | Suitable medium | Diameter |

| Rubber | Neoprene(CR) | -20~60℃ | Slurry, paper pul,p etc. | DN65~DN1600 |

| Natural Rubber(NR) | ||||

| Polyurethane Rubber(PU) | Slurry, paper pulp etc. | DN25~DN500 | ||

| Silicone rubber | -20~180℃ | Water | DN40~DN1600 | |

| Fluoroplastic | PTFE(F4) | -20~120℃ | Corrosive acid-base salt liquid | DN10~DN1600 |

| Teflon F46(FEP) | -40~160℃ | Corrosive acid-base salt liquid | DN10~DN200 | |

| PFA | -40~160℃ | Corrosive acid-base salt liquid | DN10~DN300 |

Integrated vs. Split Structure

An integrated electromagnetic flowmeter combines the sensor and converter into a single, integrated structure. This compact design reduces pipeline installation workload and simplifies installation and maintenance.

A split-type electromagnetic flowmeter consists of a sensor and a converter. The sensor is installed on the measuring pipe to detect fluid flow. The converter, installed at a certain distance from the sensor (usually no more than 100 meters), receives the sensor signal, processes it, and displays and outputs it. This structure allows for flexible placement and combination of the sensor and converter, tailored to specific needs.

Installation of an integrated electromagnetic flowmeter requires simply mounting the entire device on the pipe, eliminating the need for additional wiring. This simple and quick installation method is ideal for applications with limited space or restricted installation conditions.

Installation of a split-type electromagnetic flowmeter requires installing the sensor separately on the pipe and connecting it to the converter via a cable. This installation method is more complex and requires more wiring, but it can be flexibly adjusted to suit the site’s environment.

With its compact structure and advanced communication capabilities, the integrated electromagnetic flowmeter is suitable for applications with limited space and a high demand for data exchange.

Because the sensor and converter can be installed separately, split-type electromagnetic flowmeters are suitable for applications where the on-site measurement environment is poor and remote display is required. For example, in environments with high temperature, high humidity, high vibration, or corrosive gases, split-type electromagnetic flowmeters can ensure the accuracy and stability of measurement data.

More Flow Measurement Solutions

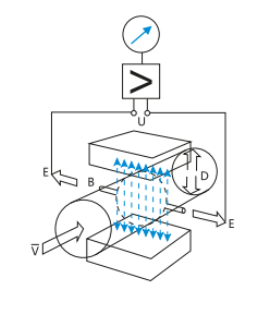

Magnetic flow meters are based on Faraday’s law of electromagnetic induction, measuring flow by measuring the electromotive force induced by a conductive liquid in a magnetic field. Their split structure design and PTFE lining provide significant advantages in corrosion resistance and adaptability.

Split structure magnetic flow meters feature separate sensors and converters. The sensor can be placed in high-temperature, high-pressure, or corrosive environments, while the converter is located in a safe area. Signals are transmitted via cables, protecting the electronic components from harsh operating conditions.

Sino-Inst is a professional supplier of magnetic flow meters. If you require flow measurement, please feel free to contact us.

-1.jpg)