Insertion Magnetic Flow Meters are configured for use with conductive liquids in DN100~DN3000 (4″ ~ 120″) pipe. A selection of materials (stainless steel, brass, and PVC) allows the meter to adjust to a range of temperatures, pressures, and corrosive environments.

With no moving parts, these meters can be used in “dirty” applications where debris would foul a mechanical meter. We’ll explore insertion mag meter technology in this blog post.

What is an Insertion Magnetic Flow Meter?

An insertion magnetic flow meter is a type of plug-in electromagnetic flow meter designed to be inserted into a pipe through a small opening, allowing it to measure the velocity of a conductive fluid passing by.

Unlike full-bore mag meters that require the entire pipe section to be replaced or removed for installation, insertion mag meters are installed directly into the side of an existing pipe, making them ideal for retrofit applications and large-diameter pipelines.

The main technical performance indicators of the Insertion magnetic flow meter

- Flow velocity measurement range: (0.05-10) m/s

- Measuring pipe diameter: DN (32-3000) mm

- Measurement accuracy: 0.5-1.0 level

- Working pressure: <1.6MPa

- Medium temperature: 0-80℃

- Power consumption: <20VA

- Connection mode: flange connection, threaded connection

- Working voltage: 220V, 24V

Insertion Magnetic Flow Meter Working Principle

Fundamental Components of an Insertion Mag Meter:

- Electrode Probes

- Magnetic Coil

- Housing and Mounting Assembly

- Transmitter/Electronics

The operation of an insertion magnetic flow meter is based on Faraday’s Law, which states that a voltage is induced when a conductive fluid flows through a magnetic field.

The insertion-type magnetic flow meter has a simple and reliable instrument structure and is free from blocking and flow-blocking parts, and there is no pressure loss or fluid blockage.

The measurement accuracy is not affected by the type of the measured medium and its temperature, viscosity, density, pressure, and other physical parameters.

The insertion type magnetic flow meter has a variety of models, including pipeline type and plug-in type, and can be used for detecting liquid flow rates of water, sewage, acid, strong alkali, and other conductivity above 5us/cm.

Advantages of Using an Insertion Mag Meter

- Cost-Effective for Large Pipes

- Minimal Invasive Installation

- No Moving Parts

- Bidirectional Flow Measurement

- Adaptability to Existing Systems

Applications of Insertion Magnetic Flow Meters

- Water and Wastewater Treatment

- Irrigation Systems

- HVAC and Building Automation

- Chemical Processing

- Mining and Slurry Applications

- Food and Beverage Industry

Installation Considerations for Insertion Mag Meters

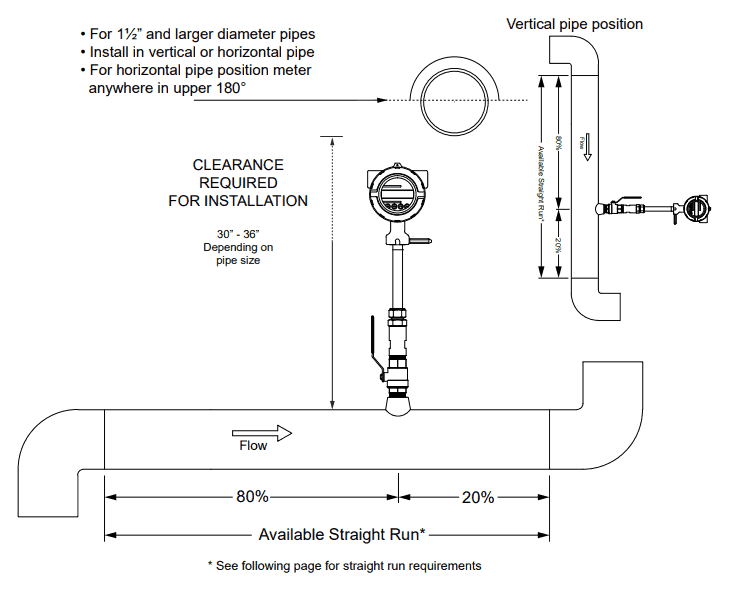

The insertion type magnetic flow meter sensor should be installed in the upstream straight pipe section not less than 5D (D represents pipe diameter), and the downstream straight pipe section is not less than 2D.

There are two installation methods, vertical and inclined installation. The axis of the sensor and the axis of the pipeline being measured are at an angle of 45° for inclined installation. The insertion point of the sensor can be inserted into the central axis of the pipe under test (that is, 1/2 times the pipe diameter) or into the inner wall of the pipe at 1/4 of the pipe.

Maintenance and Troubleshooting

- Inspect Electrodes Periodically: Buildup on the electrodes can affect accuracy. Clean them as needed.

- Check Grounding: Loose or corroded grounding wires can introduce electrical noise.

- Firmware and Calibration: Keep firmware updated and re-calibrate according to manufacturer recommendations.

- Monitor Diagnostic Alarms: Many meters offer built-in diagnostics that can alert users to conditions like empty pipe, grounding fault, or electrode coating.

More Flow Measurement Solutions

- Sewage Flow Meters and Effluent Flow Meters for Wastewater

- Gear Flow Meter Technologies: Oval, Spur, and Helical

- More Convenient Flow Measurement-Battery Operated Flow Meters

- Complete Guide for Micro Motion Flow Meters

- Guide For Syrup Flow Meters

- Everything You Need To Know About Propane Gas Flow Meters

- Opt The Right Flow Meter For Soy Sauce Flow Measurement

- Dirty Water Flow Meters

- Potable Water Flow Meters In Domestic Water Supply Systems

Regarding energy measurement, the insertion type magnetic flow meter is an important means to manage energy scientifically, realize energy saving and consumption reduction, and improve economic efficiency. It is an important part of energy measurement instruments for commonly used energy sources such as water, wastewater, chemical solutions, etc.

From water utilities to industrial plants, insertion magnetic flow meters continue to gain popularity due to their practical design and dependable operation. When chosen and installed correctly, they can deliver years of accurate and maintenance-free service. Sino-Inst is always ready to serve customers to find their best flow measurement solutions.

-1.jpg)