In industrial production, torque sensors are widely used on rotating or non-rotating mechanical parts to monitor torque. The industrial applications of torque sensors is mainly to convert torque into electrical signals. Of course, it can also detect speed, power, etc. at the same time.

It can be said that torque and speed sensors are indispensable and important tools in industry. They are widely used and effectively ensure production efficiency and product quality.

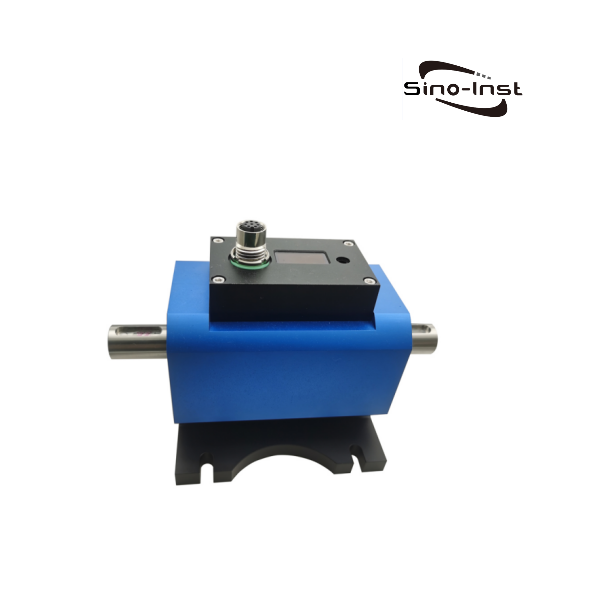

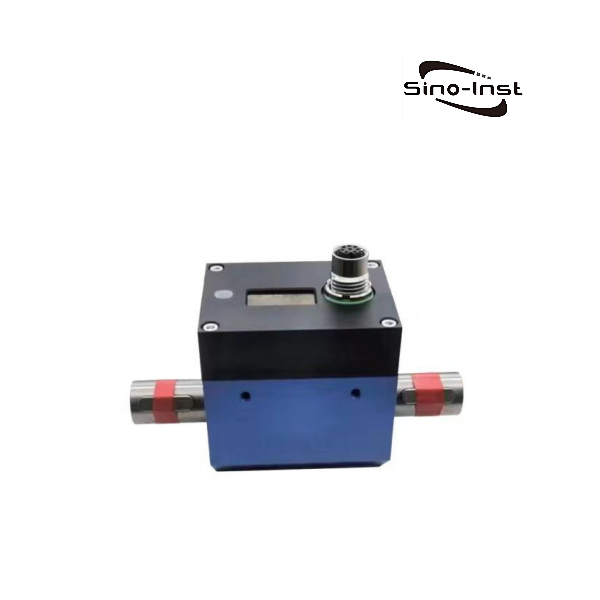

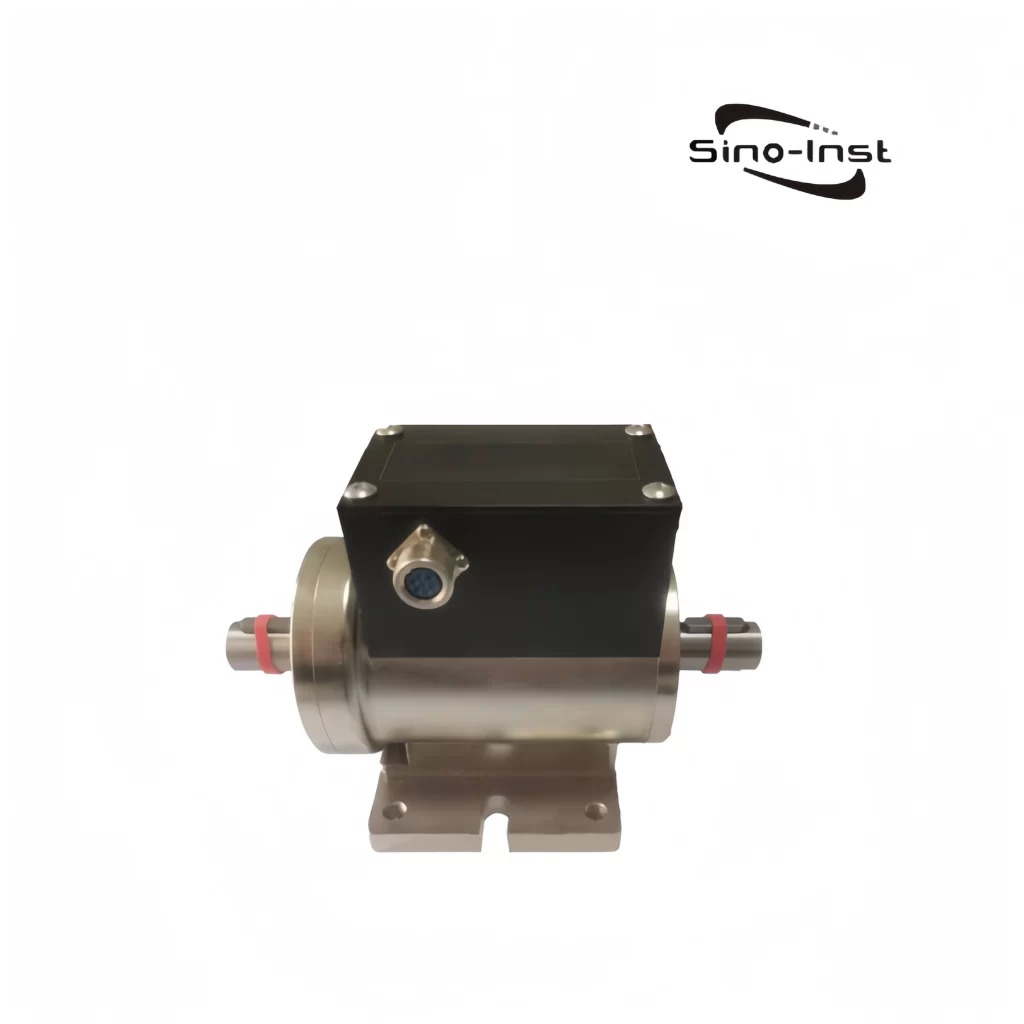

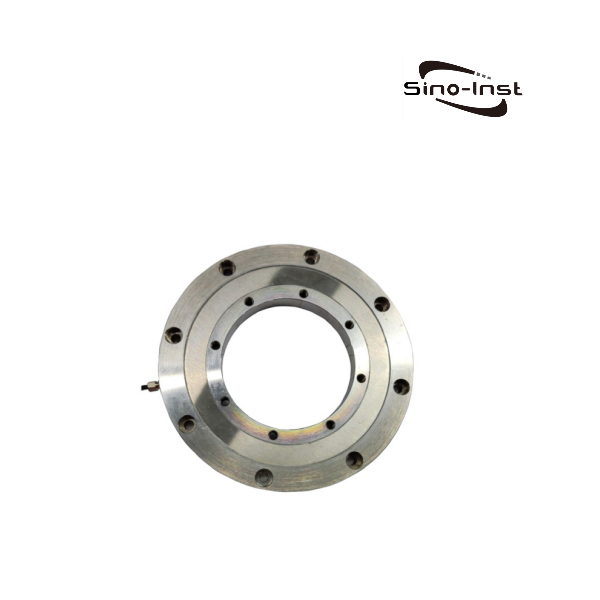

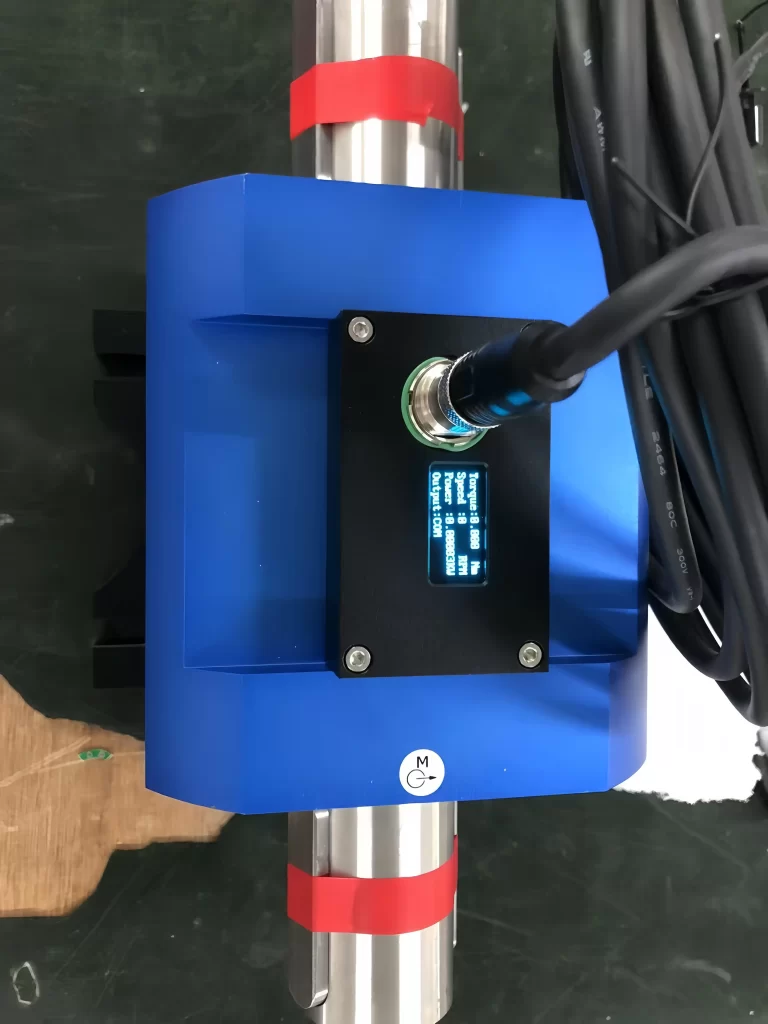

Featured Torque Sensors

Featured Industrial Applications

As a precision measuring instrument for measuring various torques, speeds and mechanical power, torque sensors are widely used in industrial production. Torque sensors can be found in engineering manufacturing, transportation, scientific research institutes and other places.

The following is a detailed description of some specific application cases of torque speed sensors in engineering:

1. Automotive Industry

In the automotive industry, torque sensors can be used to measure the output torque of the engine, so as to obtain the acceleration performance and fuel consumption of the car. In addition, torque sensors can also be used in the four-wheel drive system and electric power steering system of the car to achieve the distribution and control of wheel torque.

Engine test:

In the engine bench test, the torque speed sensor can accurately measure the torque output and speed change of the engine at different speeds and loads. Provide data support for engine performance optimization and quality control.

Transmission system monitoring:

In the transmission system of the car, the torque speed sensor can monitor the torque and speed of the drive shaft in real time to ensure the normal operation of the transmission system. This is of great significance for improving the transmission efficiency of the car, reducing energy consumption and extending the life of the transmission system.

Electric power steering system:

The torque speed sensor plays a decisive role in the electric power steering system. It can sense the torque force and steering angle generated by the steering wheel when the driver is steering. The control information is converted into a digital signal and input into the control unit to achieve power assistance. This not only improves driving comfort and safety, but also reduces the energy consumption of the steering system.

2. Industrial Robots:

In the field of industrial robots, torque sensors can be used to measure the joint torque of robots, so as to achieve precise control of robot movement.

In addition, torque sensors can also be used for load perception of robots to achieve autonomous obstacle avoidance and self-protection of robots.

3. Wind power generation:

In the field of wind power generation, torque sensors can be used to measure the output torque of wind rotors to obtain the conversion efficiency of wind energy.

In addition, torque sensors can also be used for torque control of wind rotors to achieve the adjustment of wind rotor speed and load.

4. Mechanical transmission system:

In mechanical transmission systems, torque sensors can be used to measure the output torque of transmission systems to obtain the transmission efficiency of the system.

In addition, torque sensors can also be used to achieve load control and fault diagnosis of transmission systems.

5. Aerospace

In the field of aerospace, torque and speed sensors are used to monitor the performance of aircraft engines, propellers and transmission systems.

By monitoring the changes in engine output torque and speed, signs of engine performance degradation or failure can be detected in time to ensure the flight safety of the aircraft.

Torque speed sensors can monitor the torque and speed of propellers in real time to ensure the normal operation of propellers. This is of great significance for improving the flight performance and stability of aircraft.

6. Shipbuilding and marine engineering

In shipbuilding and marine engineering, torque speed sensors are used to monitor the performance of ship engines, propellers and transmission systems.

By monitoring the changes in the output torque and speed of ship engines, signs of engine failure or performance degradation can be discovered in time to ensure the normal navigation of ships.

Torque speed sensors can monitor the torque and speed of propellers in real time to ensure the normal operation of propellers. This is of great significance for improving the navigation speed and stability of ships.

7. Medical devices

In medical devices, torque speed sensors are also used in some precision surgeries. For example, in orthopedic surgery, doctors need to use torque tools to fix bones.

Torque speed sensors can monitor the torque and speed output of tools during surgery in real time to ensure the accuracy and safety of surgery.

More customized torque-pressure measurement and control solutions

- How to Measure Torque?

- What Is a Rotary Torque Sensor?

- Customized Case: High Temperature and High Pressure Pressure Measurement -100MPa-700℃

- Featured Gauge Pressure Transmitters for Industrial Process Pressure Measurement

- Gauge Pressure vs Absolute Pressure | Differences and Relationships

- Industrial Water Pressure Sensors | Selection Guide

Torque and speed sensors can improve equipment performance, ensure safe operation and extend service life.

When selecting a torque sensor, in addition to considering and understanding all the specifications and parameter requirements of the application, key factors such as accuracy, operating environment, physical size and mechanical interface, and electrical output required for connection to the measurement system must also be considered.

If you have specific application scenarios or selection questions, please feel free to consult! We can recommend the most suitable torque sensor products and technical solutions for you based on your equipment type, measurement requirements (accuracy, range, speed), installation space, environmental conditions, etc.

-1.jpg)