GF90 Explosion proof flow switch is a type of flow meter specially used in hazardous locations. The explosion proof mark is ExdIICT6 Gb. It is suitable for explosive hazardous environments in Zone 1 and Zone 2, IIA, IIB, and IIC, and the ignition temperature group is T1~T6, where there is an explosive mixture of flammable gas or steam and air.

It is designed based on the L.V.King heat exchange principle. The explosion proof flow switch can be widely used in flow detection in flammable and explosive places such as petroleum, chemical industry, electric power, and metallurgy.

Features

- No mechanical moving parts, corrosion-resistant, stable and reliable, long life, no special maintenance required for long-term operation;

- The detection probe and signal processing circuit are designed as one, which is extremely convenient to install and use;

- The built-in temperature compensation circuit minimizes the error caused by the medium and ambient temperature on the flow rate of the fluid;

- The new circuit is selected, the circuit generates less heat, the device is installed with chip, and the reliability is high;

- This product has a built-in analog output, output 4…20mA.

GF90 Explosion Proof Flow Switch Technical Specifications

| Power supply: | DC24V±15%/100mA. |

| Medium temperature: | -45~270℃ |

| Relative humidity: | 5%~95% |

| Nominal pressure: | 0~5Mpa |

| Flow rate range: | Gas flow rate: 0.2~30m/s, Liquid flow rate: 0.01~10m/s |

| Protection level: | IP65 |

| Explosion-proof level: | ExdⅡCT6 Gb |

| Contact capacity: | DC24V/3A |

| Power-on stabilization time: | ≤3 minutes. |

| Connection cable: | RVV4×1.0. Outer diameter: 10mm±0.5mm. |

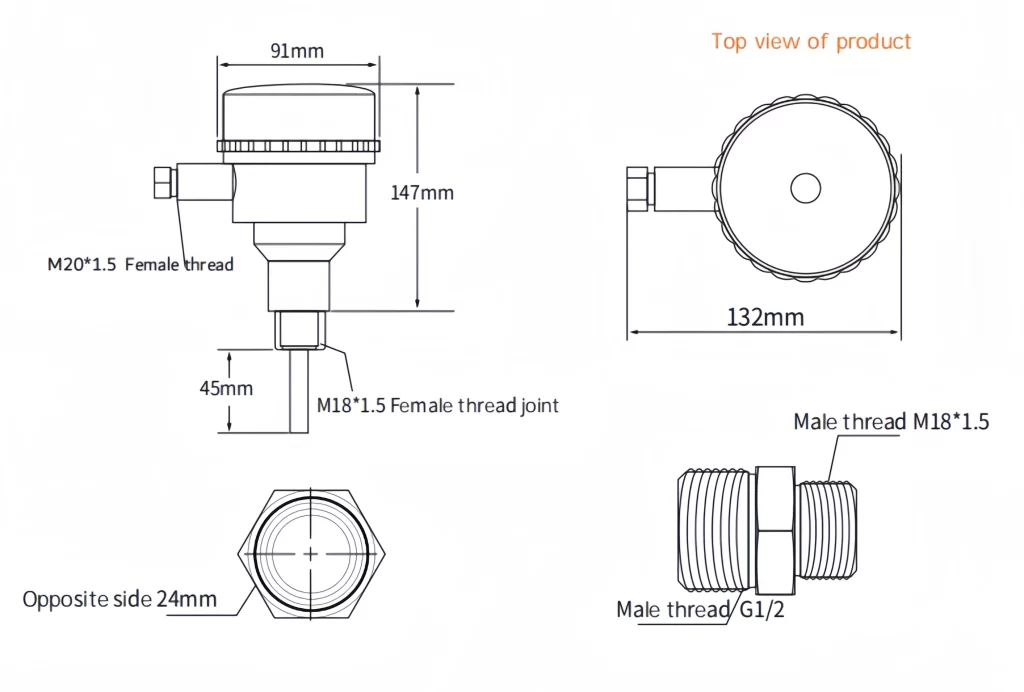

| Installation method: | Thread G1/2, NPT1/2, G3/4, NPT3/4, flange and other structures. |

Working Principle of Explosion Proof Flow Switch

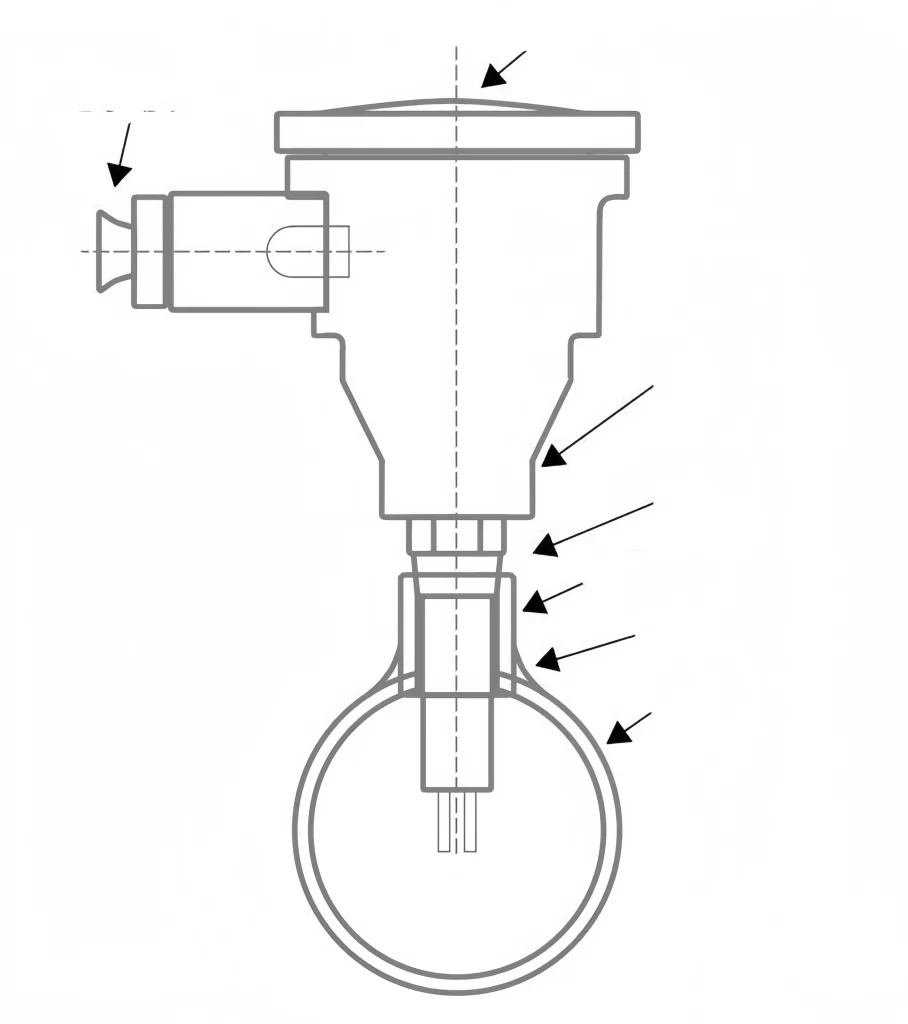

The explosion-proof thermal flow sensor is designed based on the L.V.King heat exchange principle. A flow sensor is installed at the front end, and there are two resistors in contact with the medium.

One measures the temperature of the medium, and the other measures the temperature and is heated. When there is no medium flowing, the temperature difference between the two resistors is the largest. When there is medium flowing, the temperature difference between the two resistors becomes smaller.

The size of the temperature difference is related to the flow rate of the medium. The larger the flow rate, the smaller the temperature difference. The smaller the flow rate, the larger the temperature difference. The temperature difference is the largest when there is no flow.

It is also related to the thermal conductivity and temperature of the medium itself. When the flow rate is lower than or higher than a certain set value, the relay is connected or disconnected, and the switch signal is output.

Installation method

In the horizontal (preferred) direction of the high-temperature pipeline, the length of the straight pipe section is ≥50cm. Open a circular hole with the same diameter as the welding short-circuit in the middle and upper part of the straight pipe section. Weld the short-circuit attached to the flow switch to the circular hole. Then screw the flow switch with the sealing rubber ring installed on the short-circuit.

Recommendation: The high-temperature pipeline near the flow switch should be insulated to reduce the heat conduction of the high-temperature pipeline to the flow switch housing.

Wiring

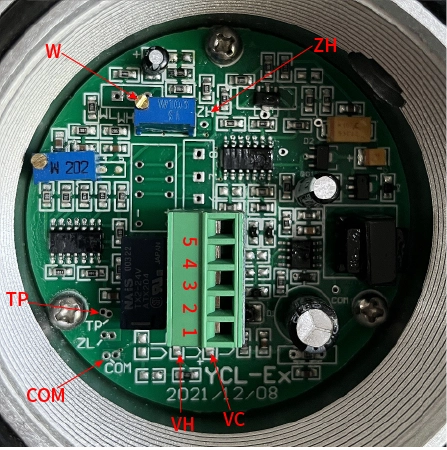

- Terminal 1: DC24+;

- Terminal 2: DC24-;

- Terminal 3: Normally closed contact;

- Terminal 4: Wiring common terminal;

- Terminal 5: Normally open contact.

- VC power indicator, VH over-limit indicator.

When wiring, first introduce the cable into the flow switch housing. Unplug the terminal connector. Connect the cable and the terminal connector according to the output properties of the instrument. Insert the terminal connector into the female socket and tighten the cable connector.

More Featured Industrial Flow Switches

We, Sino-Inst, focus on supplying high-reliability explosion-proof flow switches for industrial processes. These flow sensors are suitable for almost all liquids, gases and slurries. We support customization, including pressure range, high temperature (Max270℃), insertion depth, etc.

Sino-Inst has many years of experience in the application, design and manufacture of flow, level and pressure switches. Our products are widely used in related industries in various countries. Support OEM. If you need to purchase explosion-proof flow switches. Please can contact our sales engineers at any time!

-1.jpg)