Fluid Level Measurement is very important in the industrial and civil fields. It is convenient to accurately grasp the height of the liquid, or the distance between the liquid and the top of the container. When you need Fluid Level Measurement, you have a variety of options in front of you. Including float level gauge, capacitive level gauge, radar level gauge, etc.

We will introduce the principles, advantages and disadvantages, applications, etc. of various types of level gauges in a simple and easy-to-understand way. In order to help you choose the most suitable product.

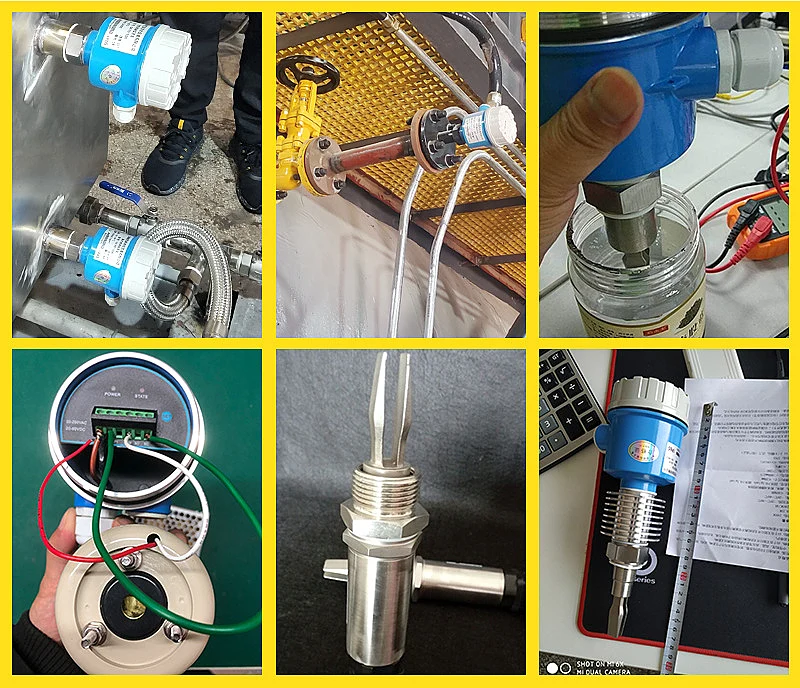

With the development of science and technology, from the ancient ruler to the modern radar level meter, there are many different solutions for fluid level measurement methods. Sino-Inst produces and supplies magnetic float level gauges, float level gauges, servo level gauges, differential pressure flow meters, radar level gauges, ultrasonic level gauges, external level gauges, paddle level switches and vibration level switches.

You may not know these complicated types. In simple terms, we can divide them into two categories: non-contact and contact.

Next, let’s look at non-contact fluid level measurement.

Non-Contact Fluid Level Measurement

1. Radar level meter

Working principle: Radar level meter uses the time difference between transmitting microwave signal and receiving reflected signal to calculate liquid level. The most commonly used one is 80G radar level meter.

Advantages:

- High precision;

- Not affected by temperature, pressure and steam;

- Applicable to high temperature and high pressure environment;

- The measuring range can reach 150m;

Disadvantages:

- High price;

- High requirements for installation environment;

Applications:

Suitable for large-scale and high-precision measurement.

In addition to conventional petrochemical, pharmaceutical and power industries, it can also be used for liquid level measurement in high temperature and high pressure environments, such as boilers and reactors.

2. Ultrasonic level meter

Working principle: Ultrasonic level meter calculates liquid level by emitting ultrasonic signal and measuring its reflection time.

Advantages:

- Non-contact measurement;

- Simple installation;

- Applicable to various liquids and solids;

- For sealed tanks, you can choose an external ultrasonic level meter.

Disadvantages:

- Greatly affected by temperature, humidity and pressure;

- The accuracy is slightly lower than that of radar level meter;

Applications: In addition to the conventional cement and beverage industries, it can also be used in situations where there is foam or agitation on the surface of the liquid.

Read more about: Ultrasonic Level Transducer: Working Principle,Types and Benefits

3. Photoelectric level meter

Working principle: Photoelectric level meter uses the principle of light refraction and reflection to detect liquid level changes through photoelectric sensors.

Advantages:

- High precision;

- Fast response speed;

- No contact, not affected by pollution;

Disadvantages:

- Affected by light conditions;

- Limited scope of application;

Application: Suitable for level measurement of transparent or translucent liquids, such as mineral water, alcohol, etc.

Next, other level meters need to contact the medium to measure the level.

Contact Fluid Level Measurement

4. Float Level Meter

Working principle: The float level meter converts the change of liquid level into an indication signal through mechanical or magnetic transmission by the principle that the float rises and falls with the liquid level.

Advantages:

- Simple structure, easy to install and maintain;

- Can be customized as a float level transmitter or a float level switch.

- Low cost;

- Applicable to various liquids;

Disadvantages:

- Generally low accuracy;

- Greatly affected by liquid fluctuations;

Applications: In addition to conventional storage tanks, oil tanks and other occasions. It can also be used in ponds, water tanks and other occasions that require simple liquid level measurement.

5. Capacitive level meter

Working principle: Capacitive level gauge uses a capacitive sensor to measure the capacitance change between liquid and gas to determine the liquid level.

Advantages:

- High precision;

- Fast response speed;

- Non-contact measurement to avoid contamination;

Disadvantages:

- High requirements on the capacitance characteristics of the medium;

- Installation and calibration are relatively complex;

- High price;

Application: In addition to the chemical, food and beverage industries, it can also be used in water treatment, sewage treatment and other environments where high liquid level accuracy is required.

6. Magnetostrictive level transmitter

Working principle: Magnetostrictive level transmitter uses magnetostrictive effect to measure liquid level by displacement of magnetic float.

Advantages:

- High precision and high reliability;

- Not affected by liquid properties;

- Long life;

Disadvantages:

- High price;

- Complex installation and maintenance;

Application: In addition to industries such as petroleum, chemical, food and beverage, it can also be used in occasions that require long-term stable and high-precision liquid level measurement.

7. Pressure level Transmitter

Working principle: The pressure level gauge determines the liquid level by measuring the static pressure exerted by the liquid.

Advantages:

- Applicable to closed containers;

- High accuracy;

- Easy to install;

Disadvantages:

- Affected by changes in liquid density;

- Requires regular calibration;

Application: In addition to chemical plants, water treatment plants, etc., it can also be used for level measurement of viscous liquids. Such as oil inventory monitoring, etc.

8. Magnetic flap level gauge

Working principle: The magnetic flap level gauge uses the movement of the magnetic flap to flip with the change of liquid level, triggering the magnetic sensor to generate a signal to achieve liquid level measurement and monitoring.

Advantages:

- High precision;

- The reading is intuitive and convenient, and can be used with a remote transmitter to achieve long-distance data transmission;

- Corrosion-resistant, suitable for complex environments;

Disadvantages:

- High price;

- Long-term use may cause wear of magnetic components, affecting their performance and accuracy, and requires regular maintenance and replacement.

Application: Suitable for liquid level measurement in industries such as petrochemicals, pharmaceuticals, and electric power, especially in places with high environmental requirements.

9. Tuning fork level gauge

Working principle: The tuning fork level gauge uses the vibration frequency of the tuning fork to change under the influence of the liquid to measure the liquid level. It is mostly used as a liquid level switch.

Advantages:

- High reliability

- High precision

- Applicable to most liquids

Disadvantages:

- Poor adaptability to high viscosity and crystalline media

- High price

Application: In addition to the petroleum, chemical and other industries. It can also be used for liquid measurement in the food, pharmaceutical and other industries. Such as milk, juice, etc.

More Level Measurement Solutions

- Float Type Level Transmitters for Continuous Level Measurement

- All-inclusive Guide To Bin Level Measurement Systems

- An Out-and-Out Guide To Different Types Of Level Transmitters

- Bitumen And Asphalt Level Meters: Let’s Learn More About Them

- Bin Level Indicators and Controllers

- Dry Materials-Bulk Solids-Powder Level Sensors Guide

- Role of Hydrostatic Level Transmitters In Well Water Level Monitoring Process

- Water Level Pressure Transducers

- Typical Ultrasonic Level Sensor Applications and Advantages

Fluid Level Measurement can help monitor the storage of fluids or materials, control production processes, and ensure the stability and safety of system operation. Through the above detailed introduction, you can quickly understand the working principles, advantages and disadvantages, and applicable scenarios of different types of level meters.

Sino-Inst produces and supplies a full range of fluid level transmitters. If you need to measure fluid level or material level, please feel free to contact our sales engineers!

-1.jpg)