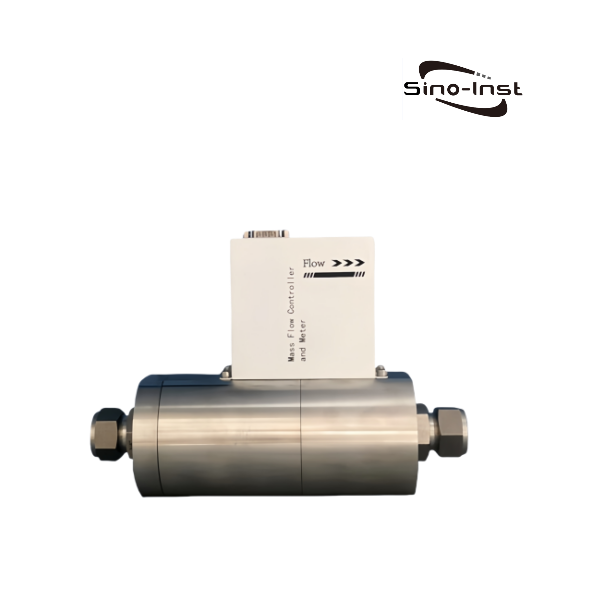

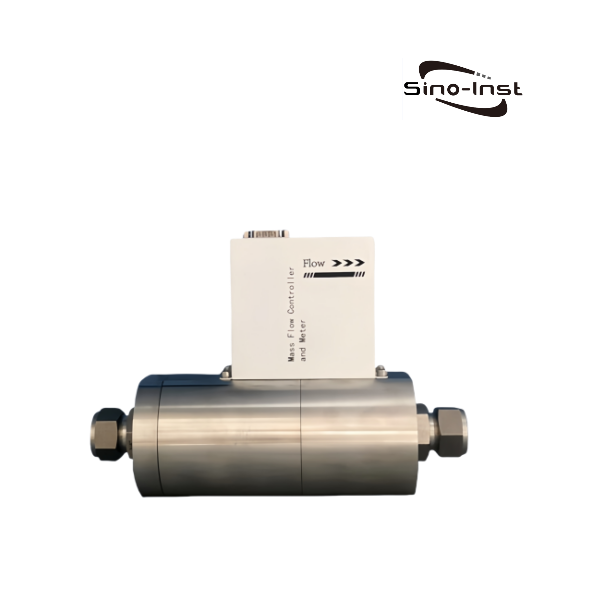

DC-B1000C series large-range gas flow controller is a thermal digital analog integrated large flow controller. The main application range is: the measurement and control of gas mass flow between 500SLM-1000SLM. The product pressure resistance can reach 3Mpa. It can monitor the gas flow in real-time and adjust it as needed to ensure that the gas flow is stable within the set range.

Features

- The ratio value is highly accurate and is not affected by any environmental factors;

- The gas distribution has high accuracy, good repeatability, fast response speed, and can meet the requirements of various gas concentration ratios;

- Convenient communication, standard communication interface, and two-way communication with computers and host computers;

- The mechanical connection structure is compact and reasonable, with a graphical perspective, and the operation is intuitive and convenient;

- The function is highly extensible and can be customized as needed;

DC-B1000 Series Large-Range Gas Flow Controller technical parameters

| Model | DC-B1000C / DC-B1000M |

| Used medium | Gas |

| Flow specification | 500SLM-3000SLM |

| Control range | 2%–100%FS. 1%–100%FS |

| Accuracy | ≤±2.0%FS |

| Repeatability | ≤±0.2%FS |

| Communication signal | RS485 Modbus protocol |

| Response time | ≤ ± 3S |

| Maximum withstand voltage | 3MPa |

| Power supply method | 15V-24V(300mA) |

Applications

Gas flow controllers with ultra-large flow rates are generally used in production enterprises and factories. They can accurately control the inflow and outflow of gas, achieve higher processing requirements, and save energy costs.

Sino-Inst’s thermal gas mass flow controllers and mass flow meters are made using a new manufacturing process. They have the advantages of fast response speed, high accuracy, stable flow control, and good linearity. They are suitable for controlling most inert and partially corrosive gases.

Widely used in high-tech companies in industries such as petrochemicals, university laboratories, research institutes, aerospace, food manufacturing, pharmaceutical manufacturing, thermal power, nuclear power, natural gas filling stations, semiconductors, solar energy, and LCD panel manufacturing.

Application of gas mass flow controller in heat treatment field

A heat treatment equipment company is a professional company specializing in ion nitriding process research and equipment production. It has accumulated rich experience in the design and production of glow ion nitriding furnaces. The main products are LD series ion nitriding furnaces, LDMC series pulsed ion nitriding furnaces, and ion nitriding furnaces with auxiliary heating.

The gas supply system consists of an ammonia bottle, an ammonia pressure reducer, a gas mass flow meter and a gas pipeline. The equipment is equipped with two flow meters, which are used for ammonia flow regulation and carburizing gas flow regulation respectively. The two gases are mixed and passed into the furnace after passing through the flow meter. The nitrogen and carbonitriding process (soft nitriding) can be achieved by adjusting the flow ratio.

Solution: Our company customized the gas mass flow controller for the enterprise according to the process requirements of this product. It is not affected by temperature, pressure and other conditions. It has been successfully installed on the equipment to accurately control the flow of the two gases. It is sensitive and has a fast response speed, which realizes the mixing ratio of the two gases. Thereby improving the carbonitriding process. The customer said that he would gradually replace the original flow meter with our company’s gas mass flow controller.

What is a gas flow controller?

The Mass Flow Controller (MFC) is an instrument used to accurately measure and control gas flow. It consists of three parts: a flow sensor, a control circuit, and an actuator.

The working principle of this device is based on fluid mechanics and heat transfer principles. The mass flow sensor measures the pressure difference and temperature change when the gas flows through the pipeline, and then calculates the mass flow rate of the gas. The gas flow rate is adjusted by controlling the valve to keep it within the set range.

More Gas flow measurement and control solutions

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

- Bin Level Indicators and Controllers

- The Next Level Of Flow Measurement: Here Come Non-Intrusive Flow Meters

The valve body of the DC-B1000 series gas mass flow controller and mass flow meter products are made of high-quality 316L stainless steel. The normal working pressure range is: 3MPa (300Br). It can meet the use requirements and usage habits of most users on the market. The DB9-pin electrical connector also facilitates the user’s disassembly and assembly during use.

In addition to providing users with a single thermal gas mass flow controller or flow meter, Sino-Inst can also provide users with a complete set of gas equipment. There are also various specifications for the connection between flow controllers and pipelines. For example, flange connections, chuck connections, clamp connections, threaded connections, etc., are basically connected to all standard-sized pipelines on the market.

If you need to purchase or customize parameters, please feel free to contact our sales engineer!

DC-B1000 Series Large-Range Gas Flow Controller | Sino-Inst

DC-B1000C series large-range gas flow controller is a thermal digital analog integrated large flow controller. The main application range is: the measurement and control of gas mass flow between 500SLM-1000SLM. The product pressure resistance can reach 3Mpa. It can monitor the gas flow in real-time and adjust it as needed to ensure that the gas flow is stable within the set range.

Product SKU: DC-B1000 Series Large-Range Gas Flow Controller

Product Brand: Sino-Inst

Product Currency: USD

Product In-Stock: PreOrder

5

-1.jpg)