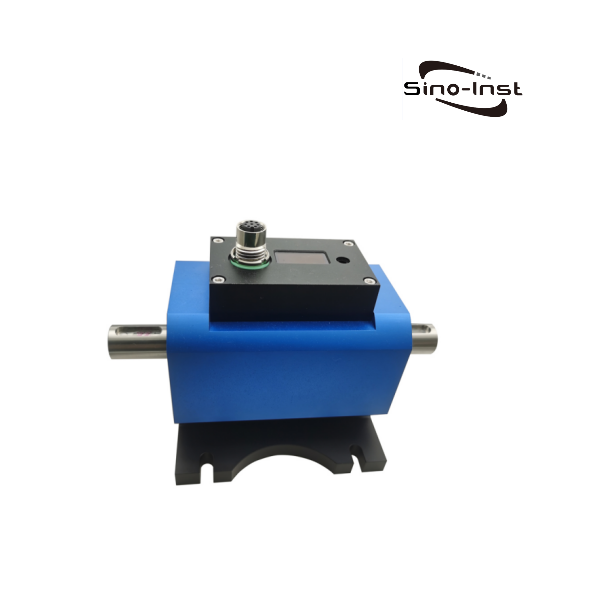

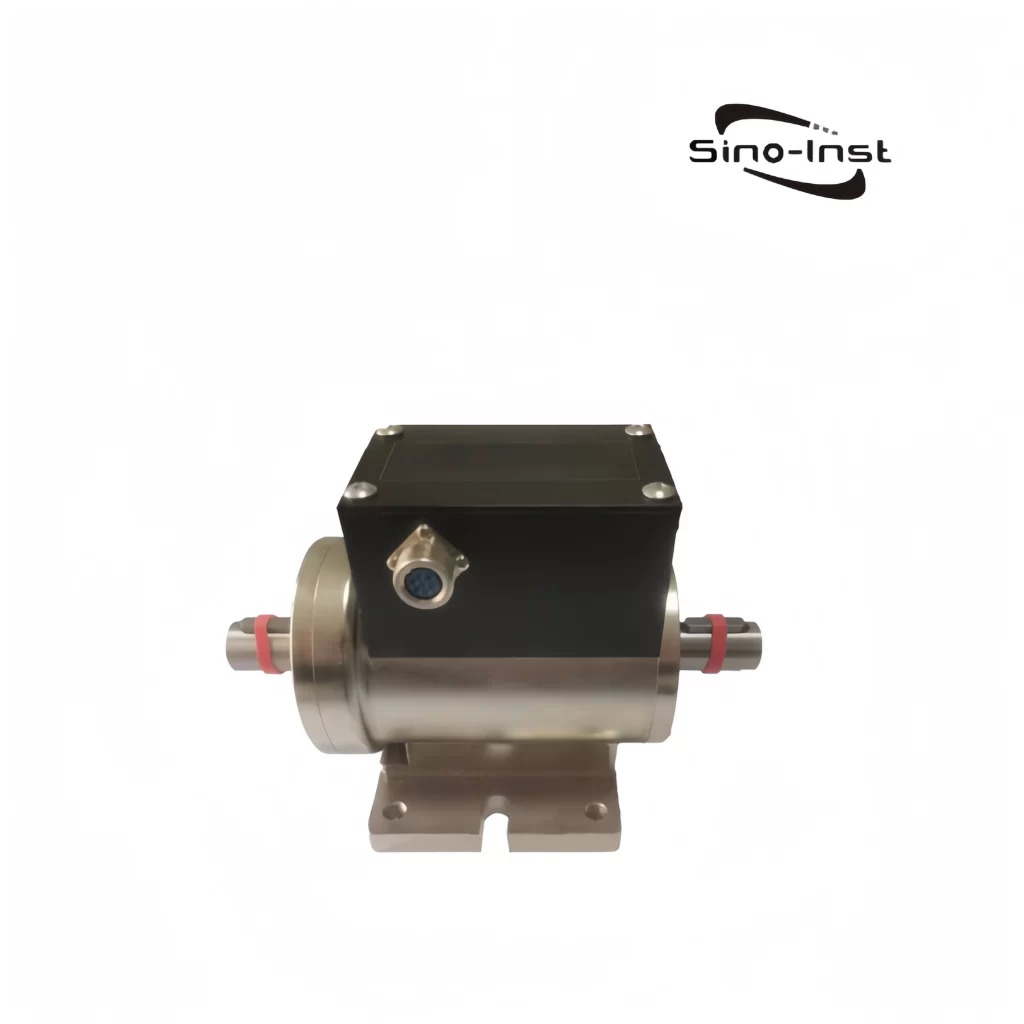

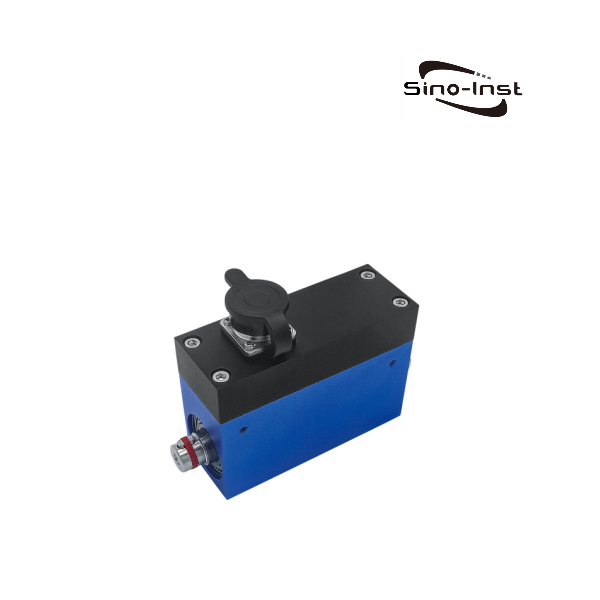

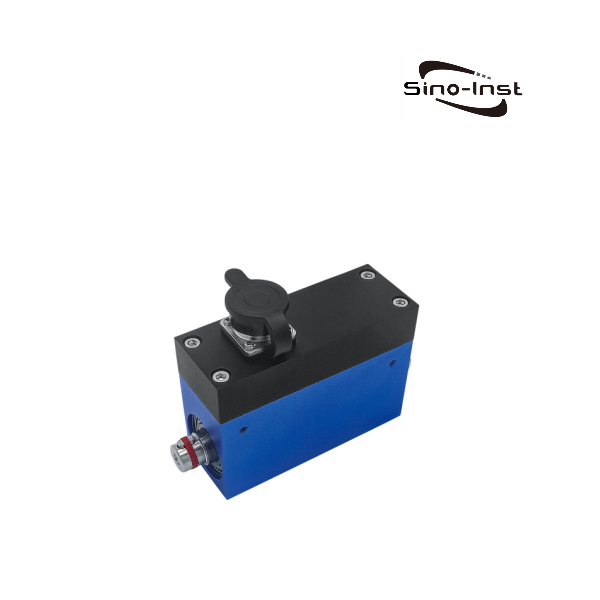

CL1-201 Dynamic Inline Torque Sensor is suitable for measuring Small Range. It can measure the electrical signal of the elastic shaft being torsion. It adopts strain electrical measurement technology to form a strain bridge on the elastic shaft, thereby providing power to the strain bridge. After the signal is amplified, it undergoes voltage-frequency conversion. It becomes a frequency signal proportional to the strain.

Features of CL1-201 Dynamic Inline Torque Sensor – Small Range

- It can measure both static torque and rotational torque;

- It can measure both static torque and dynamic torque;

- It has high detection accuracy and good stability;

- It has strong anti-interference performance;

- It is small in size, light in weight, and has multiple mounting structures, making it easy to install and use;

- It can continuously measure forward and reverse torque without repeated zeroing;

- It has no wear parts such as conductive rings, and can run at high speed for a long time;

- The sensor outputs high-level frequency signals that can be directly sent to the computer for processing;

- It can measure the strength of the elastic body and can withstand 100% overload.

Technical Parameters

| Parameters | Technical indicators |

| Rated range | 0-0.1,0.2,0.3,0.5,1~5N.m |

| Output sensitivity | 0.1-0.2Nm … 0.6 mV/V±10%F.S. 0.3-0.5Nm … 0.8 mV/V±10%F.S. 1-5Nm …1.3mV/V±10%F.S. |

| Zero output | ±2%F.S. |

| Creep | ≤0.03%F.S./30min |

| Nonlinearity | ±0.1,±0.3%F.S. |

| Hysteresis | ≤±0.05%F.S. |

| Repeatability | ≤±0.05%F.S. |

| Input resistance | 750±102 |

| Output resistance | 700±52 |

| Wiring method | Red: power +, green: signal +, yellow: shielding wire, white: signal -, black: power – |

| Temperature sensitivity drift | 0.03%F.S./10℃ |

| Zero temperature drift | 0.03%F.S./10℃ |

| Insulation resistance | ≥5000MΩ/100VDC |

| Excitation voltage | 10~15V |

| Temperature compensation range | -10~60℃ |

| Operating temperature range | -20~65℃ |

| Safe overload | 150%F.S. |

| Ultimate overload | 200%F.S. |

| Cable size | φ5.2x3m |

| Material | Stainless steel/alloy steel |

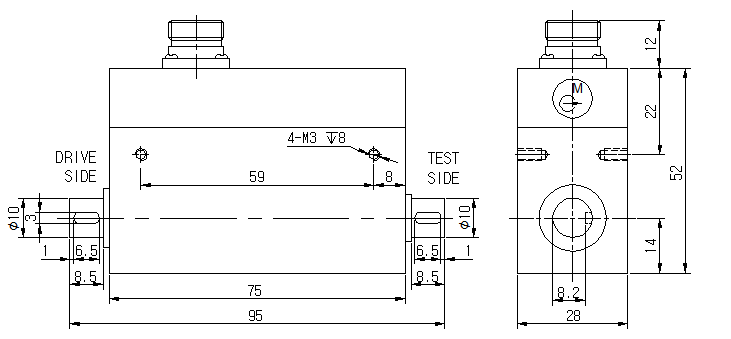

Dimensions

Inline Torque Sensor Signal Output and Signal Acquisition

1. Basic forms of torque signal output:

(1) Square wave signal, pulse signal.

(2) Voltage analog signal output or current analog signal output (unidirectional, static torque measurement) can be made according to user needs.

2. Torque signal processing form:

(1) The frequency signal output by the torque sensor is sent to a frequency meter or digital meter to directly read the frequency signal or voltage and current signal proportional to the torque.

(2) The torque and frequency signals of the torque sensor are sent to the secondary instrument of the single-chip microcomputer to directly display the real-time torque value, speed and output power value and RS232 communication signal.

(3) The frequency signals of torque and speed are directly sent to the computer or PLD for processing.

More Torque Sensors and Solutions

Inline Torque Sensor has a small range structure design and high precision. It can run at high speed for a long time and output positive and negative torque signals. Both ends are keyed.

Inline Torque Sensors produced by Sino-Inst are widely used in torque measurement of various rotating power equipment systems such as motors, mixers, reducers, transmissions, winches, internal combustion engines, etc. If you need to purchase or have related technical questions, please feel free to contact our sales engineers!

CL1-201 Dynamic Inline Torque Sensor - Small Range

CL1-201 Dynamic Inline Torque Sensor is suitable for measuring Small Range. It can measure the electrical signal of the elastic shaft being torsion. It adopts strain electrical measurement technology to form a strain bridge on the elastic shaft, thereby providing power to the strain bridge. After the signal is amplified, it undergoes voltage-frequency conversion. It becomes a frequency signal proportional to the strain.

Product SKU: CL1-201 Dynamic Inline Torque Sensor - Small Range

Product Brand: Sino-Inst

Product Currency: USD

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)