Negative pressure/vacuum environment refers to the situation where the ambient pressure is lower than the atmospheric pressure. This environment places higher requirements on the selection and use of flow meters. In order to accurately measure the flow in a negative pressure environment, we need to choose a suitable type of flow meter.

In a negative pressure/vacuum environment, thermal mass flow meters and Coriolis mass flow meters are ideal measurement tools. They can accurately measure flow and are suitable for the special conditions of negative pressure environments.

Characteristics of negative pressure flow measurement

Flow measurement is not allowed to introduce significant pressure loss. Negative pressure comes from vacuum pumps. Many powerful vacuum pumps only generate negative pressures of tens of kilopascals. For example, a vacuum pump with an inlet absolute pressure of 30kPa converts a negative pressure of only -70kPa from powerful power. If a flow meter is installed on a negative pressure pipeline, the resistance will increase, resulting in a large pressure loss. This will greatly increase power loss, which is contrary to the purpose of energy saving.

Low pressure reduces gas density, which makes it difficult to select instruments.

After the flow meter is installed on a negative pressure pipeline, if there is a leak, it is difficult to detect. Inadvertently, power is wasted.

Featured Negative Pressure-Vacuum Flow Meters

First, let’s take a look at several common types of flow meters in negative pressure environments and their working principles.

The differential pressure flowmeter calculates the flow rate by measuring the pressure difference of the fluid in the pipeline before and after the throttling device. However, it is easily disturbed by external factors in a negative pressure environment, and the measurement accuracy is affected.

The float flowmeter measures the flow rate by changing the flow area between the float and the cone tube by the float rising and falling in the vertical tapered tube with the flow rate. However, in a negative pressure environment, the stability of the float may be affected.

In contrast, thermal mass flowmeters and Coriolis mass flowmeters show better applicability in negative pressure environments.

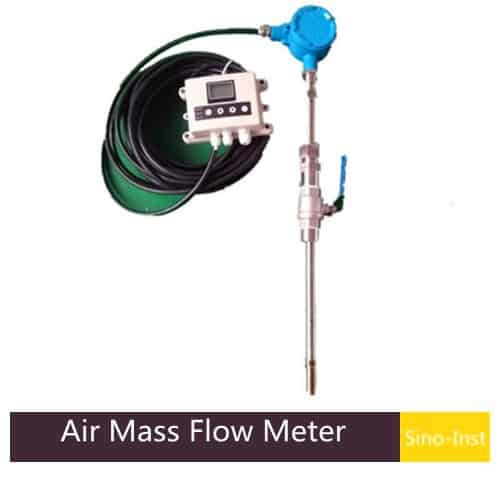

The thermal mass flowmeter uses the principle of heat diffusion to calculate the flow rate by measuring the heat loss of the heating element when the fluid flows through. It has the characteristics of fast response speed and high accuracy. It can be used for gas flow measurement in a negative pressure environment.

The Coriolis mass flowmeter uses the Coriolis force generated when the fluid flows in the vibrating tube to measure the flow rate. It has the advantages of high accuracy and high reliability, and is also suitable for negative pressure environments.

In addition, when choosing a flowmeter for negative pressure environment, it is also necessary to consider its convenience of installation and maintenance. Both thermal mass flowmeter and Coriolis mass flowmeter have the characteristics of compact structure, easy installation, and relatively simple maintenance, which can reduce the difficulty of operation in negative pressure environment.

In summary, thermal mass flowmeter and Coriolis mass flowmeter are ideal measurement tools in negative pressure environment. They can accurately measure gas flow and are suitable for special conditions in negative pressure environment.

In practical applications, we can choose the appropriate type of flowmeter according to specific needs and conditions to ensure the accuracy and reliability of the measurement results.

Utilization of Vacuum Flow Meters: The area of Applications

- Semiconductor Manufacturing

- Vacuum flow meters supervise gas delivery in wafer processing, chemical vapor deposition (CVD), and etching.

- Vacuum Furnaces

- In metallurgy and material science, vacuum furnaces necessitate fine gas flow control for atmosphere regulation during heating cycles.

- Pharmaceutical Industry

- Used in vacuum drying, distillation, and sterilization systems where controlled gas flow is indispensable for process repeatability and abidance with safety standards.

- Space Simulation Chambers

- Simulating the vacuum of space requires literal gas flow management to maintain pressure levels and thermal regulation.

- Leak Sensing and Vacuum Integrity Testing

- Precise flow meters help measure gas ingress or egress in sealed systems to determine and locate leaks.

- Medical and Laboratory Applications

- Vacuum systems are widely used in medical suction devices, vacuum pumps in labs, and sterilization units, all of which rely on accurate flow measurement.

Benefits of Using Vacuum Flow Meters: The Advantages

- High Sensitivity at Low Pressures

- These meters are capable of detecting and measuring minimal flow rates accurately, even when pressure is well below atmospheric levels.

- True Mass Flow Measurement

- Thermal mass flow meters, in particular, measure the actual mass of gas passing through. It makes them more accurate in unsteady pressure or temperature conditions.

- Skillfulness Across Gases

- Many vacuum flow meters can be designed for different gases, including nitrogen, argon, oxygen, helium, and specialty gases used in semiconductor and research fields.

- Minimal Flow Obstruction

- Most designs cause negligible pressure drops, preserving vacuum conditions and system integrity.

- Wide Measurement Range

- From very low flow (a few sccm – standard cubic centimeters per minute) to larger flows in process systems, vacuum flow meters offer scalable solutions.

Fundamental Factors to Consider When choosing a Negative Pressure-Vacuum Flow Meter

- Pressure Limit: It’s a crucial factor to consider while selecting a vacuum flow meter.

- Flow Rate Requirements: Another important consideration.

- Form of Gas: What kind of gas is used in the process is a crucial factor!!!

- Accuracy and Repeatability: No doubt an indispensable criteria!

- Output and Communication: In modern time, the exact output and communication are key!!

- Materials of Construction: Frame of the flow meter is needed to construct with a suitable material according to the area of application of vacuum flow meter.

- Installation and Mounting: The proper manual of installation should be applied while installing and mounting a vacuum flow meter.

More Flow Measurement Solutions

- Annubar Flow Measurement: Principles, Applications, And Advantages

- Insertion Magnetic Flow Meter | Better Solution for Large Diameter Pipes

- Sewage Flow Meters and Effluent Flow Meters for Wastewater

- Gear Flow Meter Technologies: Oval, Spur, and Helical

- More Convenient Flow Measurement-Battery Operated Flow Meters

- Complete Guide for Micro Motion Flow Meters

- Guide For Syrup Flow Meters

- Everything You Need To Know About Propane Gas Flow Meters

- Opt The Right Flow Meter For Soy Sauce Flow Measurement

- Dirty Water Flow Meters

Whether you’re monitoring gas flow in a semiconductor fabrication plant, maintaining pressure in a vacuum furnace, or testing in a research lab, picking out the right vacuum flow meter ensures your processes remain safe, efficient, and compliant.

By knowing how vacuum flow meters work, the types available, and what to consider during selection, you can make informed decisions that save time, reduce waste, and enhance performance.

Sino-Inst is a Professional flowmeter manufacturer and supplier from China. Sino-Inst offers over 100 flow meter products. Most of these are magnetic flow meters, and others are turbine, vortex, ultrasonic, and mass flow meters. Differential pressure flow meters are most widely used. A wide variety of flow meter options are available to you, such as free samples, paid samples.

Our flow meters are very much suitable for industrial applications. These include Cooling water, industrial gas, corrosives and brine, chemical processing, mining, Wastewater, energy, electronics, laboratories, medical, and many other industries.

Looking forward to help our customers to choose best flow measurement solutions.

-1.jpg)