- The resistance strain gauge is a sensitive element.

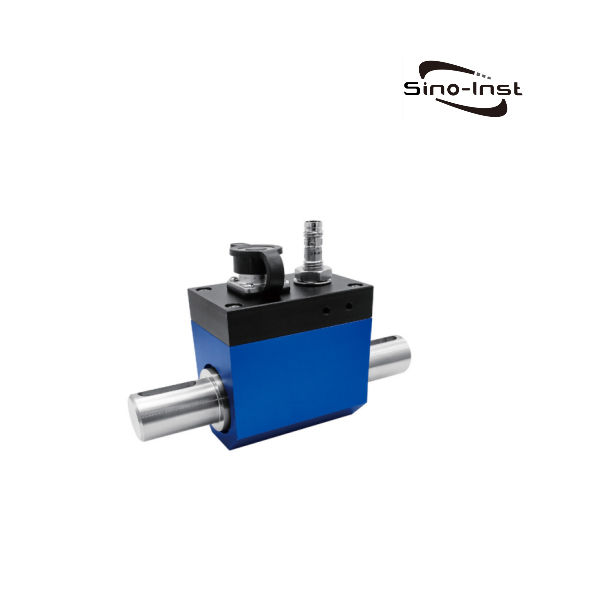

- Output forward and reverse torque signals

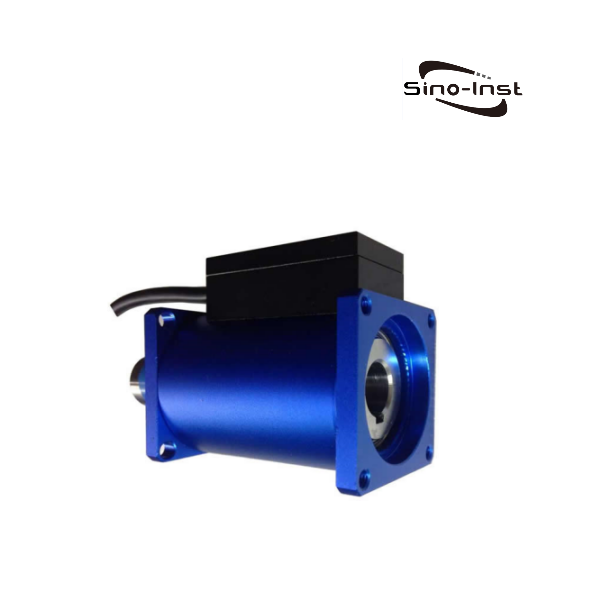

- Both ends are keyed, and easy to install and use.

- With Rotating Speed measurement. The speed can reach 1000 rpm.

- Maximum range 5000Nm.

CL1-206 Dynamic Torque Transducer Technical Parameters

| Range | 5,10,20,30,50,100-5000Nm |

| Output | 1.0-1.5mV/V |

| Accuracy | ±0.1,±0.2%F.S. |

| Zero temperature effect | ±0.03%F.S. |

| Full temperature effect | ±0.03%F.S. |

| Compensated temperature range | -10~60℃ |

| Operating temperature range | -20~75℃ |

| Supply voltage | 5-10VDC |

| Input resistance | 350±20Ω |

| Output resistance | 350±10Ω |

| Response frequency | 100μS |

| Green resistance | ≥2000MΩ/100VDC |

| Safety overload | 150%F.S |

| Ultimate overload | 200%ES. |

| Cable size | Φ5×3m |

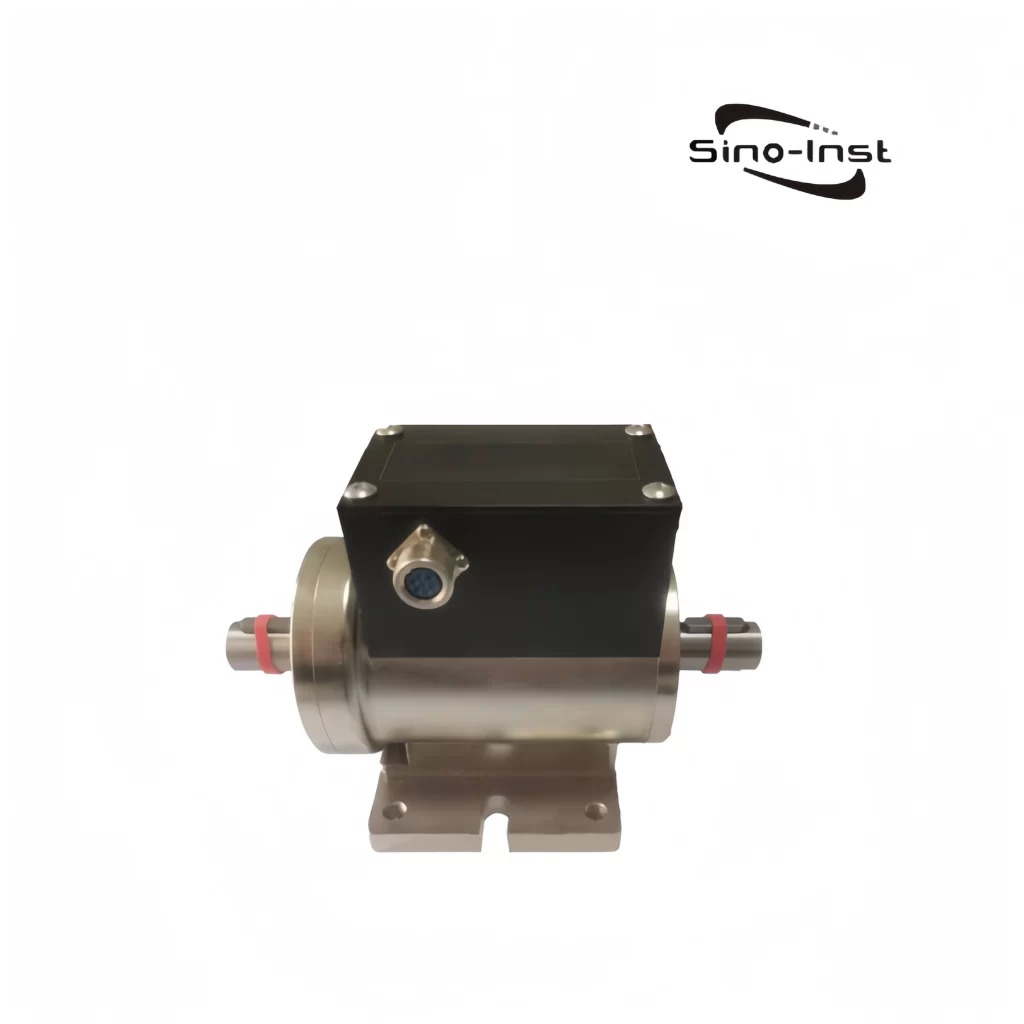

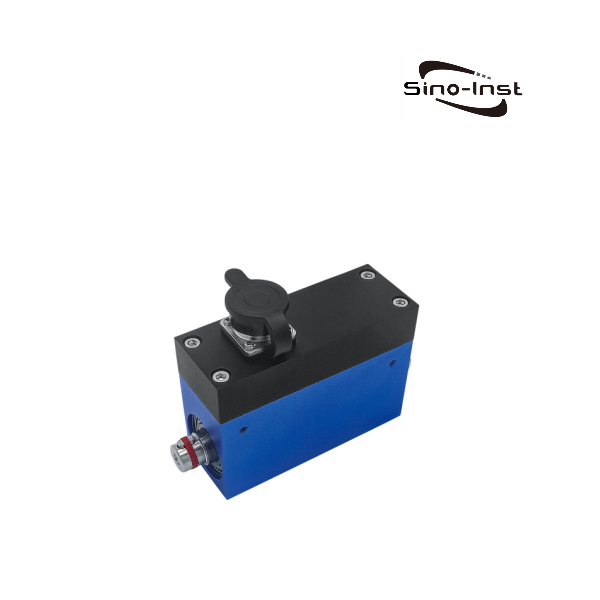

| Material | Shaft material 17-4PH stainless steel, housing aluminum |

| Electrical connection | Red/E+, black/E-, green/S+, white/S- |

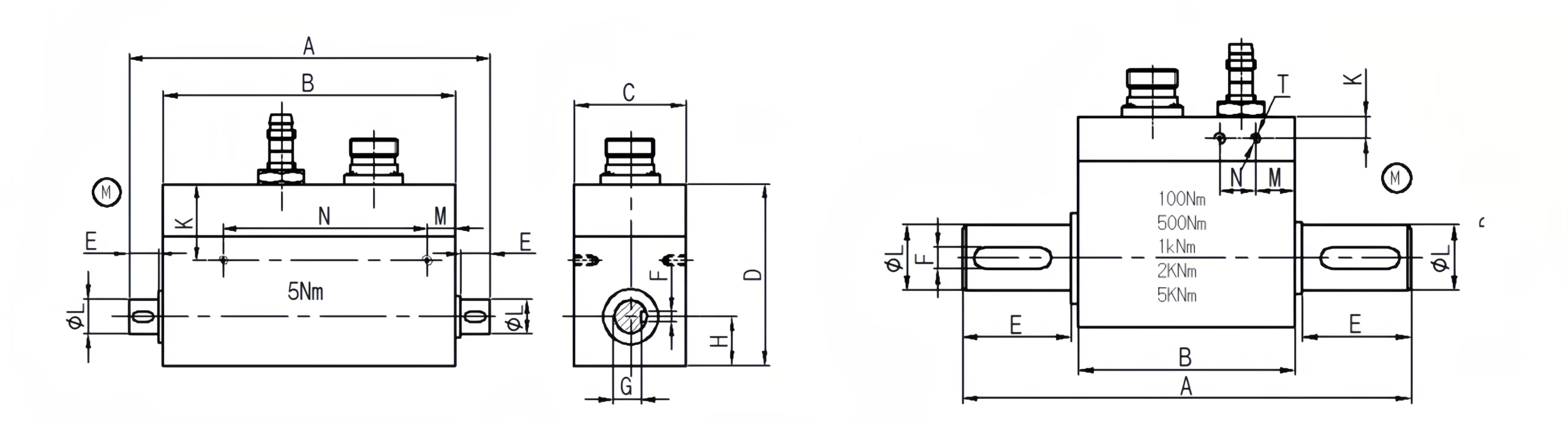

Dimensions

| Model | Cap/Nm | A | B | C | D | E | F | H | K | L | N | M | T | Applicable rotational speed |

| CL1-206A | 5 | 104 | 84 | 32 | 52 | 8.5 | 3 | 14 | 22 | 10 | 59 | 8 | 4-M3 ↓ 6 | 1000RPM |

| CL1-206B | 100 | 124 | 60 | 38 | 58 | 30 | 6 | 19 | 6 | 18 | 10 | 11 | 4-M3 ↓ 10 | 1000RPM |

| CL1-206C | 500 | 159 | 73 | 53 | 73.5 | 40 | 8 | 27 | 17 | 28 | 15 | 12 | 4-M3 ↓ 10 | 1000RPM |

| CL1-206D | 1000 | 249 | 125 | 90 | 125 | 60 | 16 | 45 | 28 | 50 | 25 | 14 | 4-M5 ↓ 12 | 200RPM |

| CL1-206E | 2000 | 298 | 132 | 95 | 128 | 80 | 16 | 47.5 | 28 | 55 | 25 | 22 | 4-M5 ↓ 12 | 200RPM |

| CL1-206F | 5000 | 367 | 157 | 139 | 171 | 100 | 22 | 67.5 | 30 | 75 | 30 | 22 | 4-M6 ↓ 12 | 200RPM |

Dynamic Torque Transducer Applications

Dynamic Torque Transducer is widely used in various industries. Including energy, automation manufacturing, aerospace, laboratories, etc. The data of torque sensors is crucial for optimizing system performance, monitoring the operating status of equipment, and performing fault diagnosis.

The following is a detailed description of some torque sensor applications in the energy industry:

Wind energy: Torque sensors are very important in wind power generation.

They are installed on the shaft of the wind turbine to measure and monitor the torque output of the wind turbine. The data can be used to evaluate the power output, speed and load condition of the wind energy device.

The data of torque sensors can also be used to optimize the performance of wind energy systems, monitor the operating status of wind energy devices, detect fault diagnosis and perform predictive maintenance.

Hydraulic energy: Torque sensors are very critical in hydropower generation.

They are usually installed on the shaft of the turbine to measure and monitor the torque output of the turbine. The data can be used to evaluate the power output, efficiency and operating status of the hydropower device.

The data of torque sensors can also be used to monitor the load changes of the turbine, detect equipment failures and perform fault diagnosis.

Gas and oil extraction: Torque sensors are widely used in the gas and oil extraction process.

They are usually installed on the shafts of hydraulic pumps, compressors, generators and other equipment, and the data can be used to measure and monitor the torque output of the equipment and evaluate the efficiency and operating status of energy extraction devices.

The data of torque sensors can be used to optimize the energy extraction process, monitor the reliability of equipment and perform fault diagnosis.

Power plants and power transmission: Torque sensors play an important role in power plants and power transmission systems.

They are often installed on equipment such as generators, transmissions, rotor shafts, etc., and can be used to measure and monitor the torque output of equipment and evaluate the operating status and load conditions of power generation equipment.

The data of torque sensors can be used to optimize the performance of power generation equipment, monitor the reliability of power transmission systems and predict faults.

New energy research: Torque sensors play an important role in the field of new energy research.

They can be used to measure and analyze the torque characteristics of new energy devices. For example, solar tracking systems, geothermal energy conversion devices, etc. can use torque sensors to evaluate the torque output of rotating parts and the performance of the system.

The data of torque sensors can be used to optimize the design of new energy devices, improve energy conversion efficiency and the stability of control systems.

More Torque Sensors and Solutions

Sino-Inst has been focusing on the field of torque sensors and torque measurement for many years, and can provide customers with a variety of competitive sensors and solutions. Especially in the measurement of position, angle, force and torque.

Our main advantage is to provide differentiated customization according to the personalized needs of customers, including but not limited to size, flange, circuit, accuracy, software, etc.

Flexible solutions, fast delivery, even small batches can be customized. If you want to know about related products, please contact us.

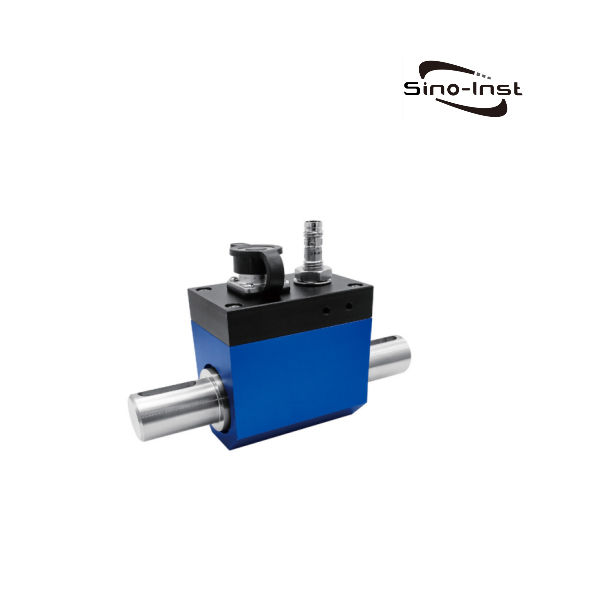

CL1-206 Dynamic Torque Transducer - with Rotating Speed

Dynamic Torque Transducer is widely used in various industries. Including energy, automation manufacturing, aerospace, laboratories, etc. The data of torque sensors is crucial for optimizing system performance, monitoring the operating status of equipment, and performing fault diagnosis.

Product SKU: CL1-206 Dynamic Torque Transducer - with Rotating Speed

Product Brand: Sino-Inst

Product Currency: USD

Price Valid Until: 2029-09-09

Product In-Stock: InStock

5

-1.jpg)