SI-S22 Inline Flow Switch can be used to detect and control the flow of flowing media in various systems, with a built-in micro-trigger switch. The principle of magnet repulsion is used to isolate water and electricity. During operation, the micro-switch does not contact low-temperature metal parts, and condensation water will not be generated. There is no rust or poor contact of the micro-switch. The setting value is adjustable and the user can adjust it according to needs.

Features

- Minimal pressure loss, good repeatability.

- Accurate switch setting is achieved through the knob.

- The mechanical part is safely isolated from the electronic part.

- Electrical components do not directly contact metal parts with large temperature differences. There is no problem of condensation water on electrical components causing rust.

- It has a variety of types for customers to choose from to adapt to different applications.

- Imported micro switches are used as electrical action components.

- The current passing through is large, which avoids the problem of easy damage to the magnetic sensitive switch due to improper use.

- It is a flow protection product that can be selected for central air conditioning and industrial fluid control.

SI-S22 Inline Flow Switch Technical Parameters

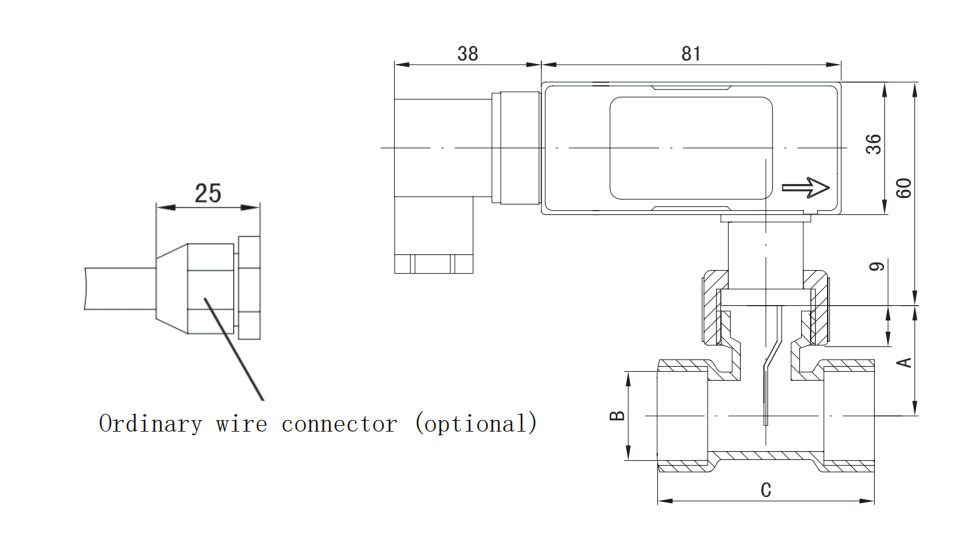

| External thread insertion interface diameter | DN20/DN25, etc. |

| Using medium temperature range | -20~110℃ |

| Storage temperature | -20~85℃ |

| Working medium | Water and oil |

| Average pressure loss | 0.01bar at large flow rate |

| Output form | Micro switch SPDT output |

| Micro switch parameters | 5A(max), 250VAC/DC |

| Cable | Standard configuration 1.5m, 2*0.75mm |

| Maximum pressure bearing | 25bar, optional customized 40bar |

| Enclosure protection grade | IP65 |

| Material | Wetted housing: brass/optional stainless steel; Baffle: beryllium copper; Seal: NBR; Electrical housing: ABS; |

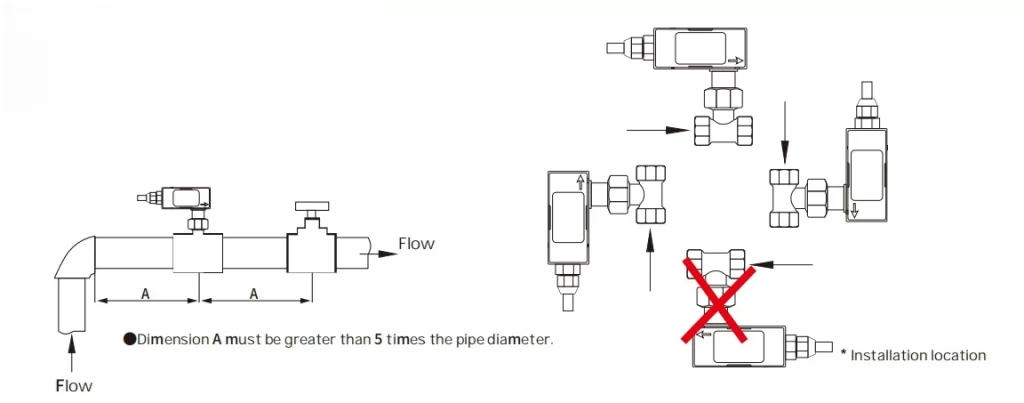

| Installation position | Horizontal, vertical; But the plastic junction box cannot be at the bottom, that is, it cannot be inverted. |

inline paddle flow switch Working Principle

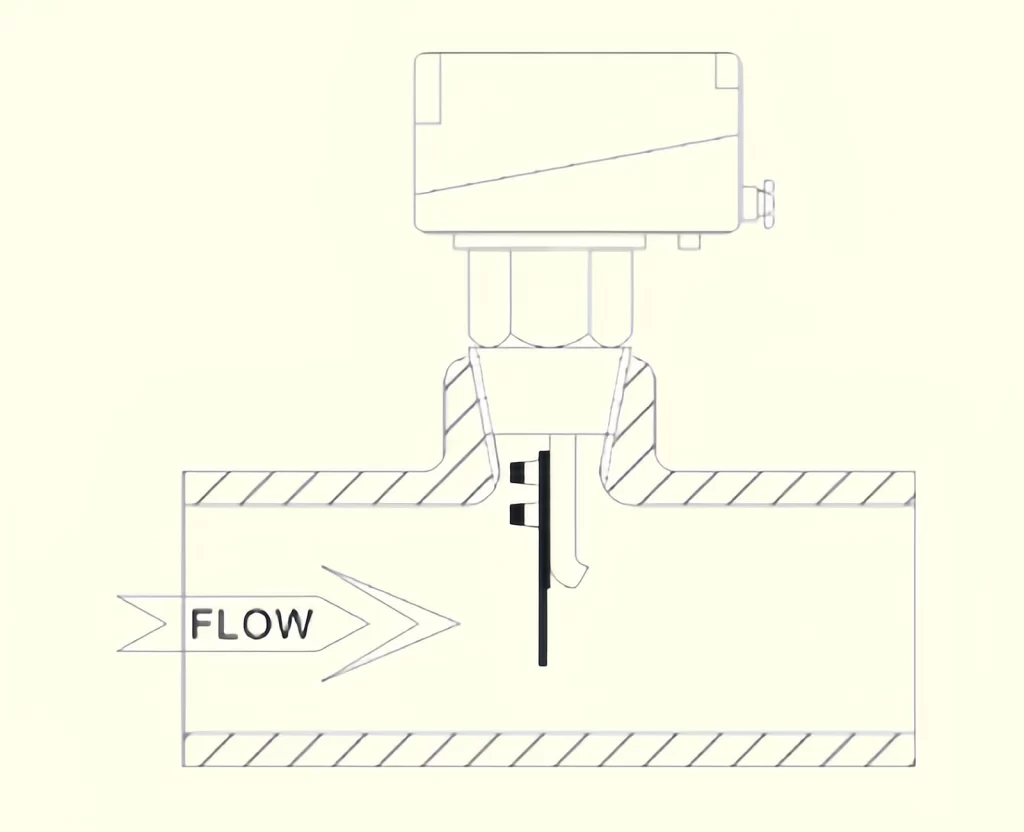

The target flow switch consists of a vane system with a permanent magnet attached to its other end. Above this magnet is a reed contactor, which is placed outside the flow.

In addition, the target flow switch has a magnet with the same magnetic properties as the previous magnet, which generates a certain force to reset the switch to the no-flow position.

When the flow rushes towards the vane, the vane swings. This changes the relative position of the magnet and the reed contactor and activates the contactor.

Once the flow is interrupted, the vane returns to the starting position and activates the contactor again.

The mutual repulsion of the two magnets provides the force required to reset the magnet. Instead of the normal spring leaf, magnetic force is used. Such a flow switch is more stable and durable, and is no longer sensitive to pressure peaks.

Inline Flow Switch Installation

The installation position of the baffle flow switch is generally installed in the pipe from the water outlet of the water pump to the water outlet of the equipment. It is best not to install it on the pipe of the suction port of the water pump, which will easily make the water pump unable to absorb water normally. The water flow switch cannot be opened. Pay special attention to this point.

The baffle flow switch allows horizontal (plastic part on top) and vertical installation.

Note: When installing the baffle flow switch, it is necessary to pay attention to the direction of the water flow in the pipe must be consistent with the direction of the arrow on the flow switch junction box, otherwise the water flow switch will not work. In addition, do not move the black plastic shell by hand, otherwise the flow switch will not work.

Order Guide

- Interface thread: G1/2, G1, internal thread (other threads can be customized)

- Installation: plug-in, straight-through.

- Wetted material: plastic, nickel-plated brass, stainless steel

- Electrical interface: Hirschmann connector, flying lead.

- Number of switch points: 1 switch point, 2 switch points.

- 1. When ordering, please specify the medium flow direction, medium type, pipe diameter and expected setting value. We can help you complete the setting before delivery.

- 2. If it is a viscous medium, please specify the viscosity, temperature and medium type.

- 3. If it is a gas medium, please specify the pressure (gauge pressure/absolute pressure), temperature and medium type.

More Flow Switches

SI-S22 Inline Flow Switch is a gas-liquid dual-purpose type, which can be widely used in industrial automation/mechanical equipment/air compression industry/refrigeration and air conditioning fields. Industrial applications include water-cooled welding machines, laser equipment cooling systems, vacuum coating machines, electric furnaces, polysilicon ingot furnaces, etc.

S22 series baffle flow switches can be used in corrosive air environments. Reliability, service life, operating temperature range, working pressure and requirements for the operating environment are far superior to ordinary target flow switches.

If you need to purchase inline padde flow switches, please feel free to contact our Sino-Inst sales engineer!

-1.jpg)