Among the several types of flow meters available in the market, helical flow meters attract attention due to their precision and ability to handle high-viscosity fluids and challenging flow conditions. Helical flow meters are extremely accurate measuring instruments to determine the volume flow rate of liquids in closed pipelines.

This article explores the working principles, benefits, applications, and installation considerations of helical flow meters.

Knowing Helical Flow Meters

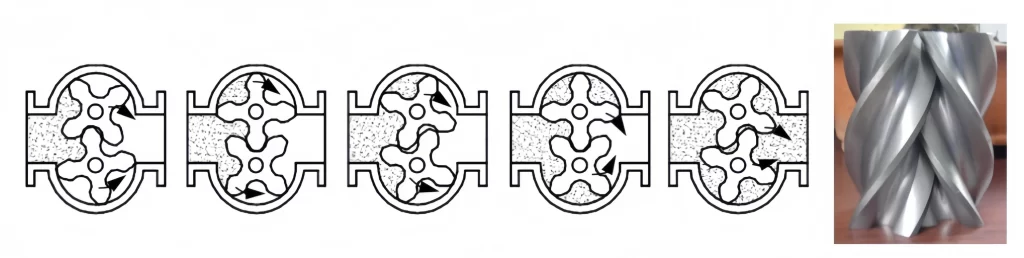

Helical flow meters are characteristic volumetric flow-measuring devices that directly measure the quantity of flowing liquid by means of a couple of rotors known as helical rotors. It is a kind of positive displacement flow meter according to the Roots principle.

A helical flow meter is a kind of bi-rotor flow meter positive displacement. It can be a mechanical type flow meter or equipped with electronic Bi-rotor transmitters. A digital display and frequency to current converters are available for remote totalization, recording, and presetting of metered volumes.

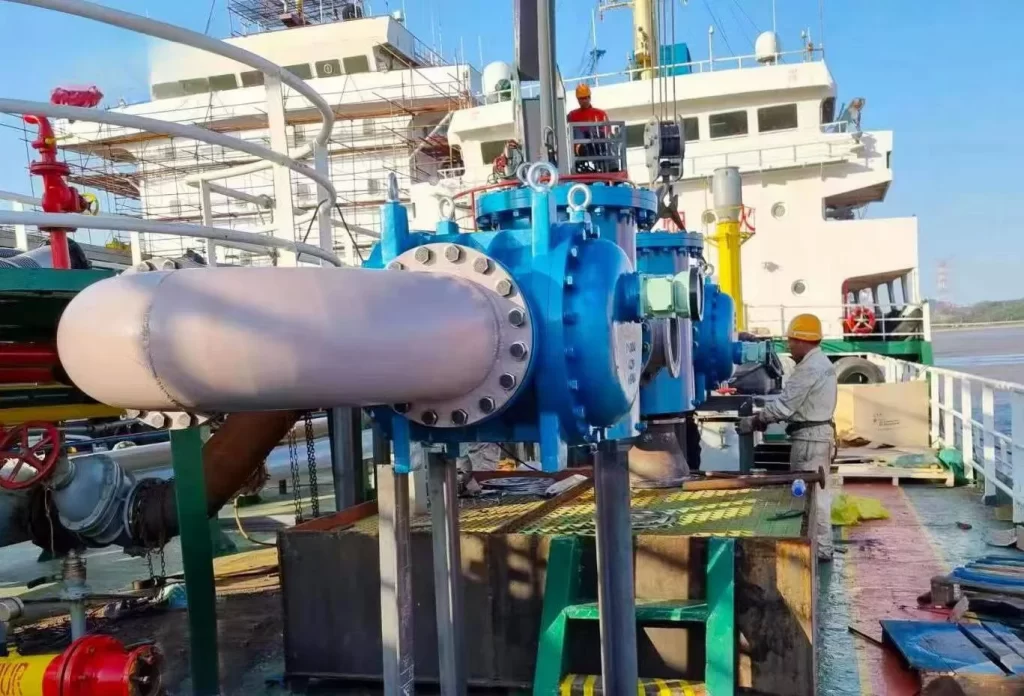

Helical flow meters may be used for custody transfer purposes, operating controls, and for the many other needs of the petroleum, chemical, pharmaceutical industry, etc.

Working Principle of Helical Flow Meters

Because of this positive displacement mechanism, helical flow meters maintain high accuracy even at low flow rates and fluctuating pressures.

Helical Flow Meter’s Characteristics

- High accuracy

- High reliability

- No pulsation

- Low noise

- Large turn down ratio

- Small pressure loss

- Can measure fluids with max 3500 cp viscosity, used as high high-viscosity Bi rotor positive displacement flow meter

- Can work on high-temperature fluids ( max 200 degrees Celsius )

- Easy calibration and easy installation

- Can be equipped with a variety of counters, speed regulators and external fine tuners;

- Can be installed vertically (please specify vertical installation requirements when ordering, and generally below DN200 diameter).

Benefits of Helical Flow Meters

- The top benefits of helical flow meters over other flow meter types include:

- Exceptional accuracy across wide flow ranges.

- Minimal pressure loss during operation.

- Superior handling of high viscosity fluids. They can handle a wide range of viscosities, from low-viscosity oils to highly viscous fluids like heavy crude oil and molasses.

- Additionally, their robust design ensures longevity and reduces the need for frequent maintenance.

- Their consistent operation ensures reliable measurement over time, crucial for billing and custody transfer applications.

- Built with robust materials like stainless steel and hardened alloys, helical flow meters can withstand harsh environments and corrosive fluids.

Applications of Helical Flow Meters

Due to their unique capabilities, helical flow meters are widely used in industries that require precise fluid measurement. Some key applications include:

Installation and Maintenance Considerations

Installation Tips

Proper Orientation: Install the meter in a horizontal or vertical position, depending on the manufacturer’s recommendations.

Flow Conditioning: Use upstream and downstream straight pipe sections to minimize flow disturbances and ensure stable readings.

Filtration: Install a filter or strainer upstream to prevent debris from entering the meter and damaging the rotors.

Temperature and Pressure Considerations: Ensure that the operating conditions match the meter’s rated specifications to avoid measurement errors.

Pulsation Reduction: If the system includes pulsating pumps, install a damping mechanism to protect the meter.

Maintenance Guidelines

- Regular Calibration

- Cleaning

- Lubrication

- Inspection: Check for wear and tear on the rotors, bearings, and seals to prevent failures.

Common fault causes and troubleshooting methods

| Fault phenomenon | Causes | Measures | Notes |

| Spiral rotor does not rotate | 1. There are foreign objects in the pipe 2. The measured liquid contains a lot of foreign objects. The filter is damaged. Foreign objects enter the meter and the gears are stuck. | Disassemble and clean the instrument and pipeline, and repair the filter. | |

| Axial seal coupling leaks | The seal packing is worn or lacks sealing oil. | The pointer, gasket, etc., are loose or the rotating parts are not flexible. | |

| The spiral rotor does not rotate | Replace the bearing, repair the metering box wall and gear at the gear change to make the rotation flexible, and ensure the required clearance. | Re-tighten to eliminate the inflexibility. | |

| Pointer rotates unsteadily or stops and moves | The rotor collides with the wall of the metering box, the bearing is worn, or the wall of the metering box is deformed. | Replace the bearing, repair the metering box wall and gear at the gear change to make the rotation flexible and ensure the required clearance. | Calibration is required after repair |

| Error changes too much | The fluid has large pulsation or contains gas. | Reduce pulsation or install a gas separator | |

| A small flow error is too negative | The service life has exceeded, or the gap has changed after maintenance. | Recheck and adjust | The maximum and minimum errors of the corresponding 0.2-level flowmeter shall not exceed 0.4% |

| The error is too large, but the difference between the maximum and minimum errors does not exceed 1% | The position of the transmitter block is improper | Re-adjust the position, move left and right, front and back | |

| The polarity is reversed | Reconnect the +” red line |

Future Trends in Helical Flow Meter Technology

- With advancements in sensor technology and digitization, helical flow meters are evolving to meet modern industrial demands. Some emerging trends include:

- Smart Flow Meters: Integration with IoT and wireless communication for real-time monitoring and predictive maintenance.

- Improved Materials: The use of advanced composites and coatings to enhance corrosion resistance and durability.

- Higher Pressure Ratings: Enhanced designs for use in ultra-high-pressure applications.

- Energy Efficiency: Development of low-friction rotor designs to minimize energy loss in fluid transport systems.

More Flow Measurement Solutions

- Bitumen And Asphalt Level Meters: Let’s Learn More About Them

- Rotary Flow Meters for More Stable Measurement and Control Systems

- Fertilizer Flow Monitoring: Liquid Fertilizer Flow Meters

- Calorimetric Flow Meter: An Economical Solution For Hot Water Flow Measurement

- Knowing Paint Flow Meters – Choose the Right One!

- Comprehensive Guide On Chlorine Flow Meters

- How To Calculate Pressure From Flow Rate And Vice Versa

- Non-Contact Flow Meters: An Advanced Approach To Fluid Measurement

- Relationship Between Pressure And Flow Rate: Key Insights

Helical flow meters are a highly reliable and precise solution for measuring high-viscosity and non-homogeneous fluids. Their ability to provide accurate, repeatable measurements across various industries makes them a preferred choice for applications requiring stringent flow control.

By understanding their working principles, advantages, and proper installation and maintenance practices, industries can leverage helical flow meters to optimize their fluid measurement processes effectively. As technology advances, these meters will continue to play a vital role in industrial flow measurement, ensuring efficiency and accuracy in critical applications.

Sino-Inst Positive Displacement meters include dual rotor types such as gear, oval gear, and helical gear types. Our expert team is always available to assist customers in making their preferred choice.

-1.jpg)