Ascertaining accurate and reliable measurement of gas flow rates is critical for a variety of industrial processes. The ability to measure gas mass flow accurately, rather than simply volumetric flow, provides insights into the true behavior of gases under varying conditions of temperature, pressure, and composition.

In this blog post, we will explore the fundamentals of mass flow meters for gas, their working principle, applications, and key manufacturers in the field. By the end, you’ll understand why thermal mass flow meters are the preferred solution for many gas flow measurement challenges.

Gas mass flow meters: In a more precise way

Gas mass flow meters (GMFM) are used in the metrology of gas flow. The core of the actual GMFM sensors is the thermal sensor consisting of a heated resistance whose value depends on temperature. In fact, the temperature of the resistance varies due the neighboring gas flow that withdraws heat from the device in a proportional way to the gas flow rate.

GMFM sensors have very significant advantages over the traditional gas measurement systems based on classic volumetric flow meters (rotameters, wet and dry meters, venturi meters, orifice plate meters, etc.), because they produce an output signal that can be used in automatic measurement and control applications.

Kinds of Mass Flow Meters for Gas

Thermal Mass Flow Meters:

Thermal mass flow meters are used in the monitoring and/or controlling of mass-related processes – such as chemical reactions – that depend on the relative masses of unreacted ingredients.

In detecting the mass flow of gases, the measurement is unaffected by changes in pressure and/or temperature. One of the capabilities of thermal mass flow meters is to accurately measure low gas flow rates or low gas velocities (under 25 ft. per minute) – much lower than can be detected with any other device.

Thermal mass flow meters are available in high-pressure and high-temperature designs. Flow-through designs are used to measure small flows of pure substances (heat capacity is constant if a gas is pure), while bypass and probe-type designs can detect large flows in ducts, flare stacks, and dryers.

Coriolis Mass Flow Meters:

The Coriolis principle is straightforward yet highly effective. It involves a tube that vibrates at a fixed frequency. As gas flows through this tube, the mass flow alters the tube’s vibration, creating a phase shift. This phase shift produces a linear output that is directly proportional to the flow rate. The Coriolis method is versatile, and applicable to any gas regardless of its type.

A Coriolis-based mass flow meter is particularly suitable when you want to measure the mass flow of varying or unknown gas mixtures or for measuring supercritical gases. The Coriolis flow meter is the ultimate flexible, reliable, and extremely accurate flow meter.

Coriolis flow meters have been successfully used to improve the accuracy and hence quality of automated extraction of natural compounds from raw materials such as plants. Here, measurement and control of supercritical CO2 flows and temperature allows selective and accurate extraction, guaranteeing repeatable yields.

Why Use a Gas Mass Flow Meter?

- Accuracy Under Varying Conditions

- Better Process Control

- Energy Efficiency

- Regulatory Compliance

Thermal Mass Flow Meters: A Closer Look

Many semiconductor processes require stable and known flows of gas be delivered to the processing chamber. The thermal mass flow meter (TMFM) is used almost exclusively in the semiconductor industry for the admission of process gases. While TMFM’s have been used in the semiconductor industry for over twenty years, much still remains to be understood about their behavior.

The TMFM’s used to measure the process gases are generally calibrated with nitrogen and ‘‘corrected’’ for other gases, but the correction factors are not well understood and are of questionable reliability. It is also important to understand how the TMFMs perform under conditions that differ from the laboratory conditions where they were calibrated and the measurement errors that are introduced as a result of these different operating conditions.

Operating Principle of Thermal Mass Flow Meters

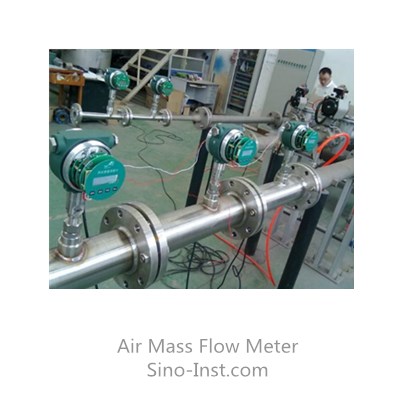

Thermal mass flow meters are precision instruments designed for direct measurement of gas mass flow across various types of gases. They operate by measuring convective heat transfer, using a probe inserted into the gas stream within a pipe, stack, or duct.

These meters are equipped with two resistance temperature detector (RTD) sensors at the probe tip. One RTD is heated by an integrated circuit, while the other serves as a reference to measure the gas temperature. As gas flows past the heated sensor. It absorbs heat, causing the sensor to cool and resulting in a temperature difference between the heated sensor and the reference sensor.

The integrated circuit compensates for the heat loss by supplying additional energy to the heated sensor to maintain the desired temperature. The amount of power required to keep the sensor at this temperature is directly proportional to the mass flow rate of the gas, providing the mass flow measurement.

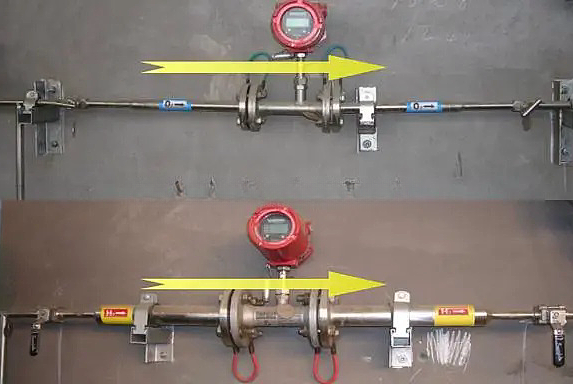

Also, in terms of operation principles, thermal mass flow meters are classified into two categories immersible and tube mass flow meters, which are respectively appropriate for high and low mass flow rates.

Applications of Thermal Mass Flow Meters

Thermal mass flow meters are used in a variety of applications, including:

- Natural Gas and Fuel Gas Flow Measurement

- Chemical Processing

- Water Treatment

- HVAC and Ventilation

- Food and Beverage Industry

- Medical and Pharmaceutical Applications

Selecting a Gas Flow Meter: Key Information

- Gas Type: Different gases have different thermal properties, which can affect the performance of the meter. Be sure the meter is calibrated for the specific gas being measured.

- Flow Range: Make sure the flow meter covers the range of flow rates required for your application, from low flow rates in a lab setting to high flow rates in industrial processes.

- Accuracy: Depending on your application, you may need high-accuracy measurements.

- Temperature and Pressure Conditions: Some flow meters are better suited for extreme temperature or pressure conditions. Ensure that the mass flow meter you select can handle the environmental conditions of your application.

- Maintenance and Durability: Look for a flow meter that is easy to maintain and durable, especially in harsh environments where reliability is essential.

Leading Gas Flow Meter Manufacturers

Brooks Instrument: Brooks is a well-known manufacturer of precision instruments, including thermal mass flow meters for a wide range of gases. World’s largest installed base of mass flow controllers. It is one of the most trusted suppliers of mass flow technology to the global semiconductor industry.

Emerson (Micro Motion): Emerson’s Micro Motion division is a leader in Coriolis flow meters and thermal mass flow meters. They offer a broad portfolio of flow measurement solutions for gases, including natural gas and air.

Sierra Instruments: Sierra Instruments is a key player in the thermal mass flow meter market, offering flow meters that are highly accurate and reliable. Their instruments are widely used in various industries.

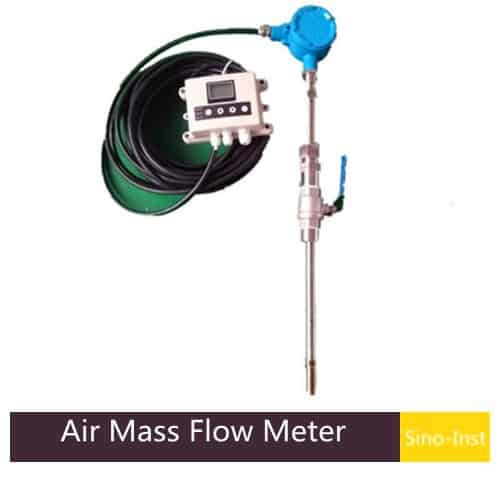

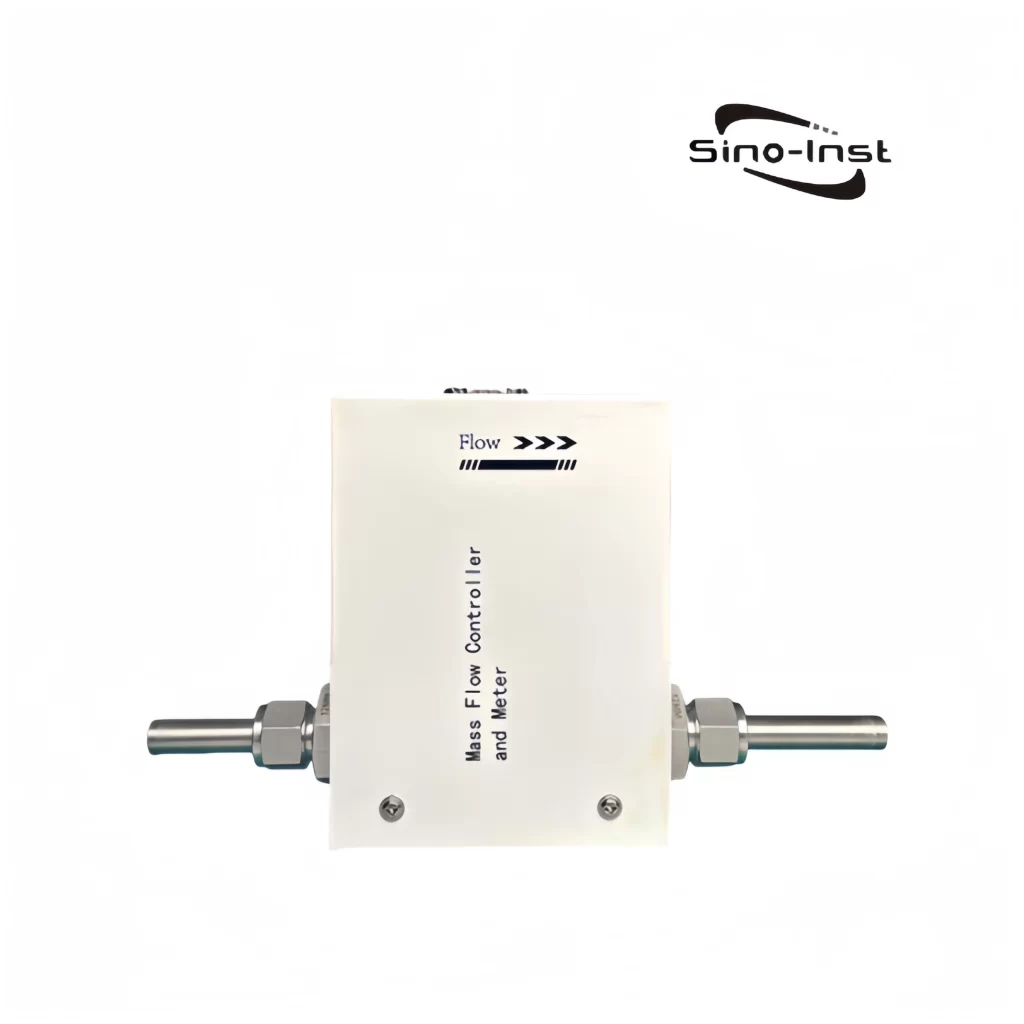

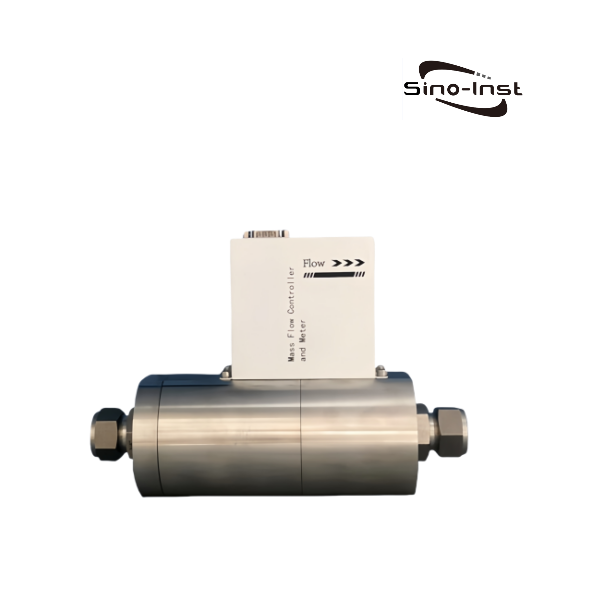

Sino-Inst: Sino-Inst is a destination of popular gas flow measurement solutions. Instruments sell through a mature distribution network that reaches all 50 states and 30 countries worldwide.

Endress+Hauser: Endress+Hauser is another global leader in process measurement technologies, including thermal mass flow meters. Their products are known for their precision and long-term reliability.

More Flow Measurement Solutions

- Types Of Mass Flow Meters And Different Measurement Techniques

- Bulk Flow Meter for Solids | Applications and Benefits

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

- The Next Level Of Flow Measurement: Here Come Non-Intrusive Flow Meters

- Right Flow Meter For Breweries: Exploring Food Grade Flow Meters

The gas mass flow meter is an essential tool for accurate, reliable, and efficient gas flow measurement across a wide range of industries. Thermal mass flow meters, in particular, offer a highly effective solution for many industrial applications, providing precise mass flow readings regardless of changing temperature or pressure conditions.

By understanding the different types of mass flow meters and selecting a trusted manufacturer, industries can ensure smoother operations and greater safety, with optimized control over gas processes. Whether in chemical processing, energy generation, or HVAC systems, gas mass flow meters play a crucial role in modern industrial infrastructure.

Sino-Inst is a professional gas mass flow meter manufacturer and supplier. We support the customization of various parameters. If you need to measure gas mass flow, please feel free to contact our sales engineers!

-1.jpg)