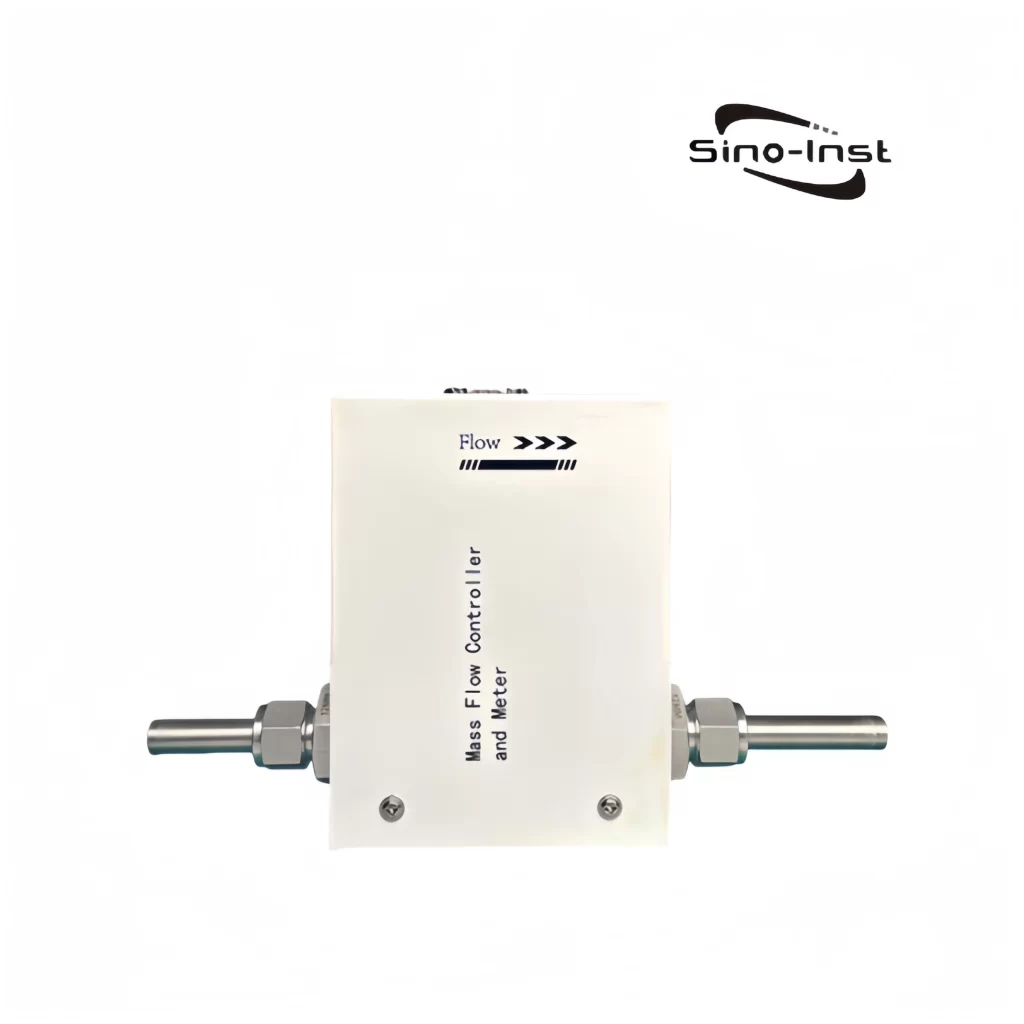

DC-M500 Digital Gas Mass Flow Controller/Flow Meter is mainly used for the measurement and control of gas flow in the range of 100SLM-500SLM. The maximum pressure resistance of the product can reach 3Mpa. It adopts a new sensor manufacturing process. It has the advantages of fast response speed, high accuracy, stable flow control, high pressure resistance, and good linearity. It is suitable for most dry and clean gases (and a few corrosive gases).

Features

- Fast response speed;

- Large flow range, wide measurement and control range;

- Strong anti-interference and high-pressure resistance;

- Wide pressure range;

- Accurate flow control;

- Support multiple analog and digital communications, long data transmission distance.

DC-M500 Digital Gas Mass Flow Controller/Flow Meter technical parameters

| Name | Mass flow controller/mass flow meter |

| Product model | DC-M500C, DC-M500M |

| Full scale | 100SLM–500SLM |

| Measurement and control range | 2%—100%F.S; 1%一100%F.S |

| Flow accuracy | ≤±2.0%F.S |

| Linear accuracy | ≤±0.5%F.S |

| Repeatability accuracy | ≤±0.2%F.S |

| Valve type | Normal closed |

| Valve body material | Stainless steel 316L |

| Response time | ≤±3S |

| Product pressure resistance | 3MPa |

| Communication signal | RS485 Modbus protocol |

| Power supply method | 15V-24V(300mA) |

| Leakage rate | 1×10-9atm.cc/sec He |

| Ambient temperature | 5-45℃ |

| Ambient humidity | 5一95%RH |

| Seal material | Fluororubber, perfluoroether rubber |

| Product weight | About 1.0一1.5kg |

| Product size | About 70×30×110(mm) |

| Installation method | Any position |

| Electrical interface | DB9 pin |

| Connector size | 1/4, 1/8, 1/2, 6mm, 8mm. |

Technical parameters:

Gas mass flow controllers/flow meters are usually calibrated with nitrogen (N2) before leaving the factory.

Mass flow unit: SCCM (standard milliliters per minute), SLM (standard liters per minute)

Standard conditions: temperature–293.15K (20℃), pressure–101325Pa (760mmHg)

F.S (Full Scale) means full scale

Applications

DC-M500 thermal digital gas mass flow controller/mass flow meter has the advantages of large flow specifications, fast response speed, high accuracy, stable flow control, wide pressure range, excellent corrosion resistance and excellent linearity. It can monitor and control various inert gases and some corrosive gases.

Widely used in:

- Petrochemical, university laboratories, research institutes,

- Bioprocess controllers

- Aerospace, food manufacturing,

- Pharmaceutical manufacturing,

- Thermal power, nuclear power, natural gas filling stations,

- Semiconductors, solar energy, LCD panel manufacturing, and other related industries.

How many MPa can the thermal gas mass flow controller/flow meter withstand?

The pressure problem of thermal gas mass flow controllers and flow meters has always been a hard technical indicator that every user is extremely concerned about. There are two pressure indicators for thermal gas mass flow controllers, namely the product’s withstand pressure and the product’s working pressure difference.

The product’s withstand pressure refers to: what is the maximum pressure that our product can withstand? The MFC and MFM produced by our company are available in 3Mpa, 5Mpa, and 10Mpa according to the flow rate and medium. Among them, the 3Mpa withstand pressure is mainly to meet the products with ultra-large flow ranges; the 5Mpa withstand pressure has the widest application range; the 10Mpa withstand pressure is suitable for products with medium and low flow ranges.

The product’s working pressure difference refers to: the thermal gas mass flow controller or flow meter, the pressure difference between the two sections before and after the inlet and outlet. The thermal gas mass flow controller has requirements for the working pressure difference. According to the flow rate, it is generally necessary to ensure: a 0.1-0.3Mpa or 0.2-0.6Mpa working pressure difference, so that the product can be opened and operated normally. If it is MFM, there is no requirement for a working pressure difference. As long as the inlet end can ensure that there is gas passing through the mass flow meter, the real-time flow can be detected.

More Gas flow measurement and control solutions

- Types Of Mass Flow Meters And Different Measurement Techniques

- Bulk Flow Meter for Solids | Applications and Benefits

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

- Frame Of Flow Meters: Stainless Steel And PTFE Flow Meters

- Sewer Flow Meters and Their Importance in Sewer Monitoring

Sino-Inst mainly provides users with thermal gas mass flow controllers and mass flow meters with various flow ranges and various communication methods.

The main advantage of thermal gas mass flow controllers and mass flow meters is that the gas flow size detected and controlled is not affected by temperature and pressure. The transmission distance is long and the response speed is fast, which is suitable for mass flow measurement and control under various standard conditions. It is suitable for a variety of media and no straight pipe section is required. A variety of input and output signals can be selected. For example analog current or voltage input and output; digital RS485 MODBUS input and output.

If you need to purchase DC-M500 Digital Gas Mass Flow Controller/Flow Meter or have related technical questions, please feel free to contact us!

DC-M500 Digital Gas Mass Flow Controller/Flow Meter - Sino-Inst

DC-M500 Digital Gas Mass Flow Controller/Flow Meter is mainly used for the measurement and control of gas flow in the range of 100SLM-500SLM. The maximum pressure resistance of the product can reach 3Mpa. It adopts a new sensor manufacturing process. It has the advantages of fast response speed, high accuracy, stable flow control, high pressure resistance, and good linearity. It is suitable for most dry and clean gases (and a few corrosive gases).

Product SKU: DC-M500 Digital Gas Mass Flow Controller/Flow Meter

Product Brand: Sino-Inst

Product Currency: USD

Product In-Stock: PreOrder

5

-1.jpg)