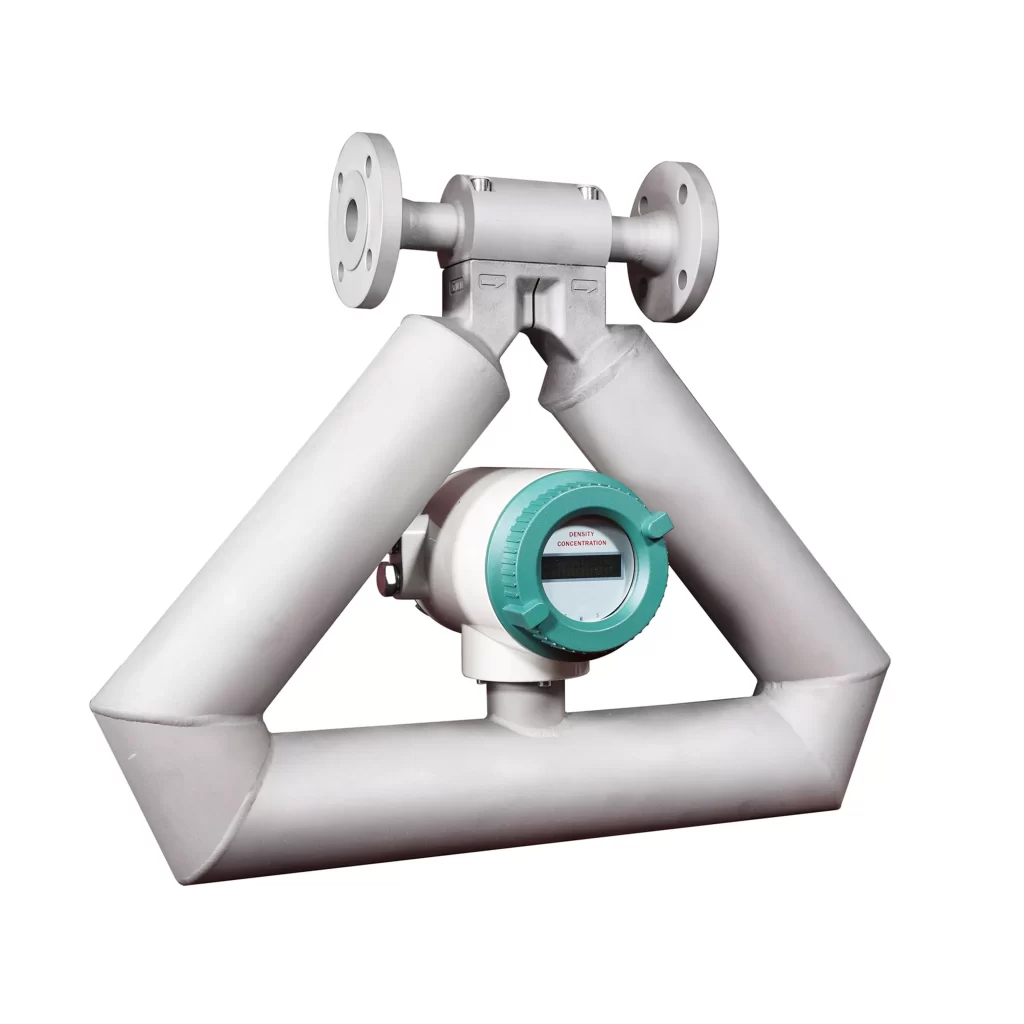

The straight tube Coriolis digital density meter measures the density of fluid flowing through a closed tube in real time using the principle of vibration. The fluid density directly depends on the vibration frequency of the vibrating tube filled with fluid. Simultaneously, a temperature sensor provides temperature compensation, and pressure and viscosity compensation are performed based on the pressure values before shipment.

Features

Technical Parameters

| Accuracy | ±0.001g/cc | ±1.0kg/m3 | |

| Operating Range | 0~3g/cc | 0~3000kg/m3 | 0~187.4 lb/ft3 |

| Repeatability | ±0.001g/c | ±0.1kg/m3 | ±0.006lb/ft3 |

| Process Temperature Effect (Corrected) | ±0.001%g/cc) | ±0.1kg/m3 | (per ℃) |

| Process Pressure Effect (Corrected) | Negligible | ||

| (1) The above accuracy applies to a calibration range of 0.6-1.25 g/cc (600-1250 kg/m³). (2) When using a long rod, the maximum liquid viscosity can reach 500 CP, but if a long rod is used, the maximum liquid viscosity can reach 20000 CP. (3) Temperature effect refers to the maximum measurement deviation caused by the process fluid temperature deviating from the factory calibration temperature. (4) Pressure effect is defined as the change in sensor flow rate and density caused by the process pressure deviating from the calibration pressure. | |||

| Signal Mode: | Four-wire system (24VDC + 4~20mA) |

| Output Signal: | 4~20mA (active output) / 485 Modbus RTU communication |

| Power Supply: | 24VDC (external resistive components or PLC cannot be connected in series) |

| Concentration Range: | 0~100% (20℃), can be calibrated to a specific range depending on usage |

| Density Range: | 0~2 g/ml, can be calibrated to a specific range depending on usage |

| Concentration Accuracy: | 0.5%, Resolution: 0.1%, Repeatability: 0.2% |

| Density Accuracy: | 0.003 g/ml, Resolution: 0.0001, Repeatability: 0.0005 |

| Explosion-Proof Rating: | Explosion-proof ExdII BT6 |

| Operating Pressure: | <1Mpa |

| Medium Temperature: | -10~60℃ (liquid) |

| Ambient Temperature: | -40~85℃ |

| Temperature Coefficient: | 0.1 kg/m³/℃ (after calibration) |

| Built-in Temperature Sensor: | PT100 |

| Medium Viscosity: | <5000 mPa·s |

| Electrical Interface: | M20X1.5 |

| Process Interface: | Various flange and clamp specifications available |

| Wetted Parts: | Titanium alloy, 316L stainless steel, special requirements available |

| Housing: | IP65, aluminum alloy |

| Maximum Working Pressure: | 1450 psi (100 bar); 3000 psi (207 bar) |

| Test Pressure: | Tested at 1.5 times the maximum working pressure |

Coriolis Digital Density Meter Working Principle

The Coriolis Digital Density Meter measures density using the vibrating tube principle. When the liquid density changes, the density of the medium affects the vibration frequency of the density meter. The change in vibrating mass affects the resonant frequency of the vibrating tube, and the resonant frequency is inversely proportional to the density of the process fluid. By detecting the change in resonant frequency, the fluid density can be obtained.

The straight-tube density meter uses a unique suspension design structure that effectively resists the influence of external vibrations on the instrument’s measurement. It also employs reliable measuring components, ensuring good performance even at high temperatures of the measured medium.

There are no flow-restricting elements inside the measuring tube; the measuring tube is a straight tube, effectively solving the pressure loss and cleaning difficulties associated with Coriolis mass flow meters when measuring density. It also overcomes the limitations of tuning fork density meters in highly viscous liquids and liquids containing solids or gases. This provides reliable technical support to ensure long-term reliable use for the user.

When the instrument is operating, the drive sensor component drives the measuring tube to vibrate, generating a sine wave. This sine wave is detected by the detection sensor component. When the density of the fluid medium changes, the resonant frequency of the instrument changes, accurately reflecting the density of the medium.

The instrument uses a mathematical processing method based on fitting equations. It also has a built-in temperature sensor for temperature compensation of the density measurement, making the density measurement more accurate.

Applications

The Coriolis Digital Density Meter is suitable for density measurement of cement slurry, mineral slurry, mortar, viscous and easily crystallizing liquids, and liquids containing gas bubbles.

- Viscous or non-Newtonian fluid media;

- Low flow rate media;

- Non-uniform mixtures;

- Media containing suspended solids or gases;

- Slurries;

- Highly corrosive fluids;

- Ultra-high and ultra-low temperature media.

Coriolis Digital Density Meter – Straight Tube Type Installation

Coriolis Digital Density Meter Horizontal Installation

Applicable: For easily flowing, non-depositing, and non-viscous fluids.

To achieve accurate measurement, install the instrument at the lowest point of the pipeline to ensure the instrument is completely filled with the medium.

Coriolis Digital Density Meter Vertical Installation

Applicable: For viscous and easily depositing fluids.

Requires bottom inlet and top outlet, proper support, and facilitates flushing and self-draining.

Coriolis Digital Density Meter Bypass Pipe Installation

Applicable: When the main pipeline is very large and the flow rate is high, bypass installation can improve cost-effectiveness.

More Density Meters for Liquids

The Straight Tube Type Coriolis Digital Density Meter is a precision instrument for continuous fluid density measurement in industrial production processes. It meets the demanding measurement needs of processes and trade transactions.

Sino-Inst’s straight tube density meter offers improved flowability and ease of cleaning. It is unaffected by vibration, flow rate, and pressure variations during operation. It is a low-maintenance, robust, and reliable instrument. Please feel free to contact us if you require customized parameters.

-1.jpg)