The SI-300C thermal dispersion flow switch is based on the principle of thermal diffusion and detects flow changes by measuring the rate at which the fluid removes heat. Two resistors are contained in the closed probe. One is heated as a detection resistor. The other is not heated as a reference resistor. When the medium flows, the heat on the heated resistor is removed. The resistance value is changed. The difference between the two resistors is used as a basis for judging the flow rate.

Features and Applications

Thermal Dispersion Flow Switch is a gas-liquid dual-purpose type. It can be used in pneumatic and hydraulic systems, and can be used for flow monitoring of circulating water, cutting fluids and lubricating oils, as well as idling protection of pumps.

- No moving parts, maintenance-free, easy to install.

- One model is suitable for various pipe diameter requirements.

- The switching value is continuously adjustable.

- Very low pressure loss.

- Compact structure.

- LED displays flow trend and switch status.

SI-300C Thermal Dispersion Flow Switch technical specifications

| Setting range: | (Water) 1…150cm/s, (Oil) 3…300cm/s, (Air) 20…2000cm/s |

| Signal output: | PNP, NPN, Relay,Analog 4-20mA, Normally Open + Normally Closed (SPDT) |

| Power supply: | 24V±20%VDC or 230V±5%VAC |

| Power on: | Maximum 400mA (PNP or NPN type), Maximum 4A (Relay type) 24VDC or 1A, 230VAC |

| No-load current: | Maximum 80mA |

| Flow indication: | LED row (6 pieces) |

| Setting method: | Potentiometer setting |

| Pressure resistance: | 100bar |

| Medium temperature change: | ≤4°C/s |

| Response time: | 1…13s, typical value 2s |

| Initialization time: | About 8s |

| Electrical protection: | Reverse phase, short circuit, overload protection |

| Protection level: | IP67 |

| Medium temperature: | -20…90°C (customizable high temperature type -40…150°C) |

| Ambient temperature: | -20…80°C |

| Storage temperature: | -20…100°C |

| Wiring method: | M12 connector/directly attached 2m cable optional |

| Material: | Probe–stainless steel (304/316 optional),Housing–PBT |

| Weight: | 0.4kg |

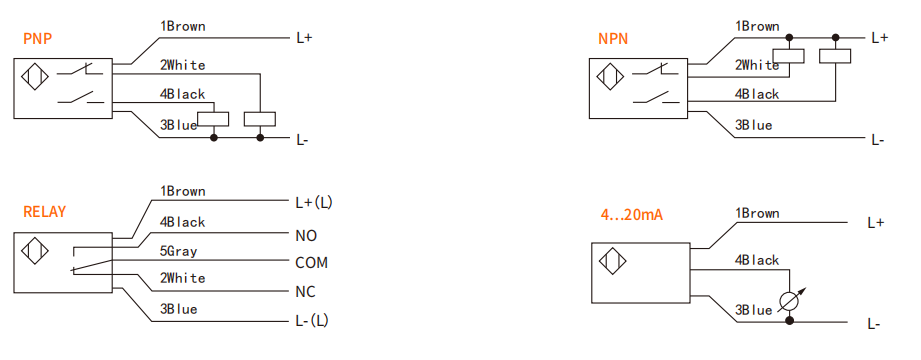

Thermal Dispersion Flow Switch Wiring Diagram

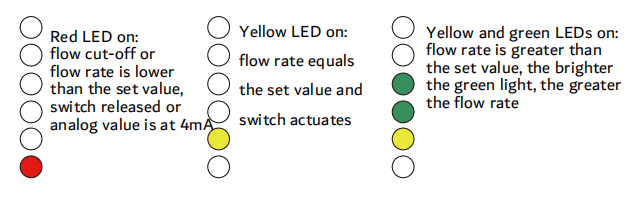

LED functions and settings

Switch type:

Install the flow switch so that the medium flows at the flow rate to be monitored. Adjust the potentiometer so that the first green LED is just lit.

After that, when the flow rate is lower than the current value, the switch is released.

If you want to make the switch point smaller than the current flow rate, adjust the potentiometer to make the green LED brighter.

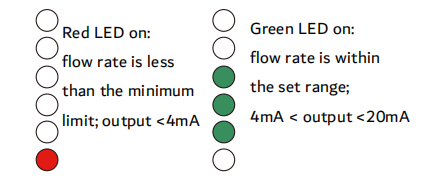

Analog type:

After the flow switch is installed, let the medium flow at the lower limit flow rate that needs to be monitored.

Adjust the lower limit knob so that the first green LED lights up (4mA).

Let the medium flow at the upper limit flow rate that needs to be detected, and adjust the upper limit knob so that the fifth green light lights up (20mA).

After that, the output will be proportional to the flow rate between the upper and lower limits, that is, 4mA corresponds to the lower limit flow rate, and 20mA corresponds to the upper limit flow rate.

Note: For analog output flow sensors, the output is 4…20mA, which is proportional to the flow rate and the output is linear. Each sensor has 2 knobs, one for “upper limit (20mA)”. The other is “lower limit (4mA)”, which is used for output setting.

How to install a flow switch?

Notes on the installation position when installing the flow switch:

- When screwing the flow switch into the pipe tee, in order to prevent damage to the switch, it is not allowed to install it by holding the casing. You must use a hexagonal wrench to hold the hexagon of the valve body for installation;

- The flow switch must be installed on a straight pipe with at least 5 times the pipe diameter on both sides.

- When tightening the flow switch, the flow plate should be perpendicular to the flow direction of the fluid. And keep the arrow direction on the flow switch housing consistent with the flow direction of the fluid in the pipeline.

- The flow switch can be installed in a horizontal pipeline or a vertical pipeline with an upward flow direction. But it cannot be installed in a pipeline with a downward flow.

- And the flow switch cannot be subjected to water hammer. If a quick-close is installed under the water flow switch, a suitable throttle must be used to prevent water hammer.

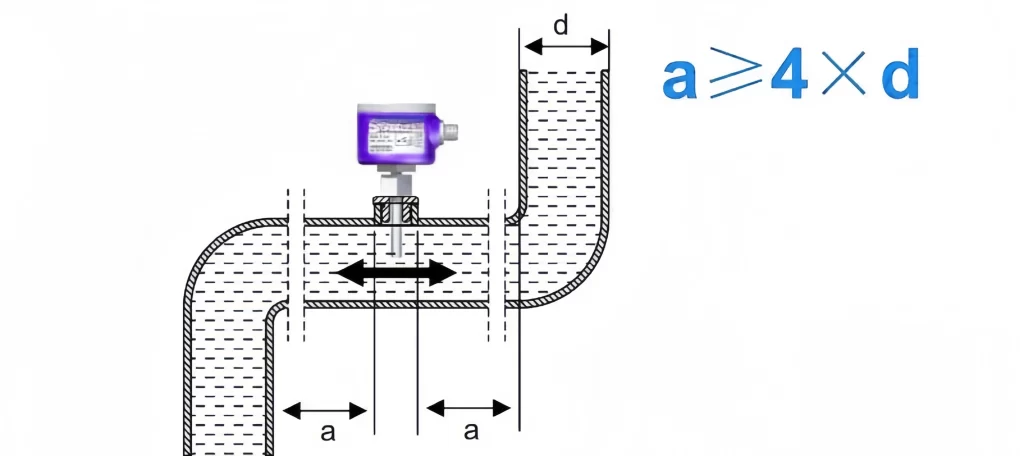

Bend installation

When there is a bend at the front end of the installed pipeline, the flow switch installation position should be no less than 4 times the pipe diameter away from the straight pipe of the bend or intersection.

Horizontal installation

When the medium in the pipeline is full, horizontal installation can be adopted.

Side installation

This side installation method can be used when the medium in the pipeline is full or not full.

Vertical installation

When installing in a vertical pipeline, it should be installed in the flow section where the medium flows from bottom to top.

Inverted installation

Inverted installation is prohibited. This installation method will cover the probe with sediment at the bottom of the pipeline, causing the flow switch to not work properly, and it is also not conducive to setting the parameters of the flow switch.

The installation joint is too long

This installation method is prohibited. If the installation joint is too long, the flow switch probe will not be able to contact the flowing medium, causing the flow switch to not work properly (in order to facilitate the installation of the flow switch by customers, the manufacturer will provide a suitable adapter according to customer needs).

Ambient temperature

The ambient temperature of the sensor installation should be between -20℃ and 80℃.

There are many types of flow switches, and Sino-Inst supplies dozens of flow switches. Each flow switch has different characteristics and different installation and use methods.

The correct selection and use of Thermal Dispersion Flow Switch parameters requires comprehensive consideration of media characteristics, process requirements and environmental conditions. Sino-Inst is experienced and provides effective flow monitoring solutions for industrial processes. If you need to purchase Thermal Dispersion Flow Switch, please feel free to contact our sales engineers!

-1.jpg)