SI-300 Thermal Flow Switch works on the thermal principle. It can monitor the flow of fluids (water, oil, air, etc.) in the pipeline in real time. The switch value is continuously adjustable. It can be used in pneumatic and hydraulic systems, and can be used for flow interruption monitoring of circulating water, cutting fluid and lubricating oil, as well as idling protection of pumps.

Thermal Flow Switch principle and structure

Thermal Flow Switch is based on the thermal principle. Two resistors are contained in the closed probe. One is heated as a detection resistor, and the other is not heated as a reference resistor.

When the medium flows, the heat on the heating resistor is taken away. The resistance value is changed. The difference between the two resistors is used as a basis for judging the flow rate.

The probe adopts an anti-scaling coating, which can effectively prevent scale, rust and other dirt from adhering to the pipeline. It has stronger anti-fouling ability and more stable operation.

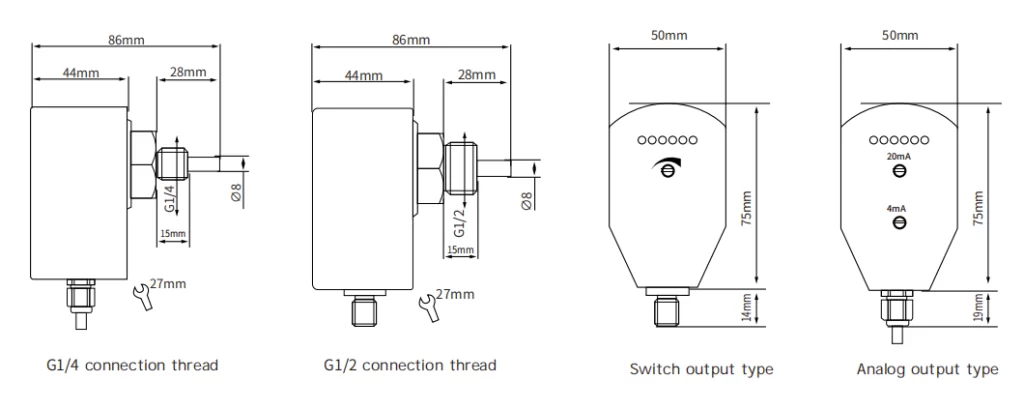

SI-300 Thermal Flow Switch Technical Specifications

| Setting range: | (Water) 1…150cm/s, (Oil) 3…300cm/s, (Air) 20…2000cm/s |

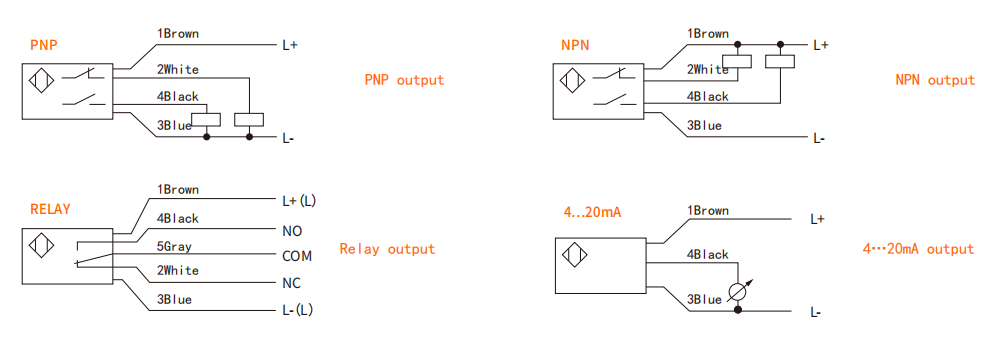

| Signal output: | PNP, NPN, Relay, Normally Open + Normally Closed (SPDT) |

| Power supply: | 24V±20%VDC or 230V±15%VAC |

| Power on: | Maximum 400mA (PNP or NPN type), Maximum 4A (Relay type) |

| No-load current: | Maximum 80mA |

| Flow indication: | LED row (6 pieces) |

| Setting method: | Potentiometer setting |

| Voltage range: | 100bar |

| Medium temperature change: | ≤4°C/s |

| Response time: | 1…13s, typical value 2s |

| Initialization time: | About 8s |

| Electrical protection: | Reverse phase, short circuit, overload protection |

| Protection level: | IP67 |

| Medium temperature: | -20…80°C (customizable high temperature type -40…150°C) |

| Ambient temperature: | -20…80°C |

| Storage temperature: | -20…100°C |

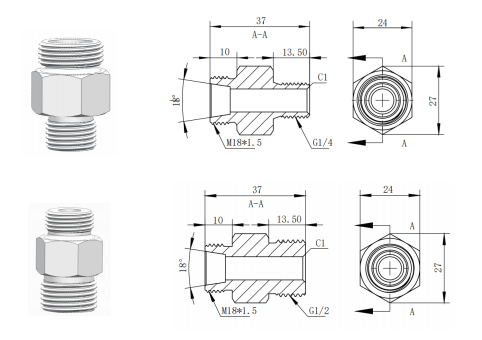

| Wiring method: | M12 connector |

| Material: | Probe–stainless steel (304/316 optional), Housing–POM (engineering plastic) |

| Repeat accuracy: | ±2% |

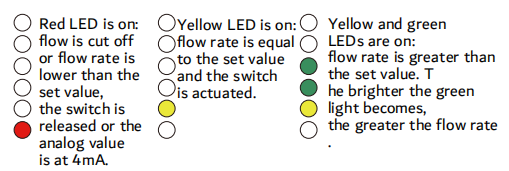

LED function and setting (switch type)

After the flow switch is installed, let the medium flow at the flow rate to be monitored.

Adjust the potentiometer so that the first green LED is just bright.

After that, when the flow rate is lower than the current value, the switch is released.

If you want to make the switch point smaller than the current flow rate, adjust the potentiometer to make the green LED brighter.

Wiring Diagram

What does a flow switch do?

A flow switch is a device used to monitor and control the flow of a liquid or gaseous medium through a pipe, system or circuit.

Flow switches perform precise functions according to set requirements. They are able to stop a motor when there is no flow and trigger the same motor to run when flow begins. When the flow stops, it sounds an alarm. When the flow reaches the appropriate level, it can turn off the alarm.

For example:

- In the event of a fire, a flow switch can trigger an electrical fire alarm to open.

- Air flow switches are used in filtration systems, exhaust ventilation and air handling systems in clean rooms.

- Liquid flow switches are suitable for chlorination of swimming pools, hot water heating, air conditioning, liquid delivery systems, fire sprinkler systems and industrial laser cooling systems.

SI-300 Thermal Flow Switch is suitable for low-cost flow control. It can automatically stop or start the corresponding equipment when the flow reaches the set value. The fluid can be controlled according to different flow ranges and set values to achieve energy saving, improve efficiency, reduce equipment loss and other effects.

Sino-Inst produces and supplies various types of flow switches. If you need to install a flow switch or have related technical questions, please feel free to contact us.

-1.jpg)