Mass flow controllers (MFC) accurately measure and control the flow rate of gases or liquids within pipelines. They not only function as mass flow meters but, more importantly, automatically control fluid flow. Even with fluctuations in system pressure or changes in ambient temperature, they maintain the flow rate at a set value.

Flow control is common in biological, chemical, food, and analytical manufacturing processes. In these applications, a controlled supply of fluids (gas, liquid, or vapor) is required. Precise flow control improves final product quality, enhances process understanding by investigating different processes, and may accelerate process steps, ultimately contributing to improved process economics.

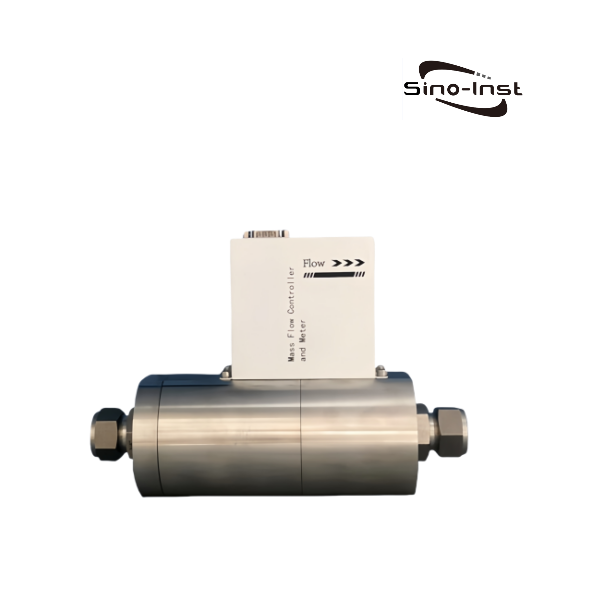

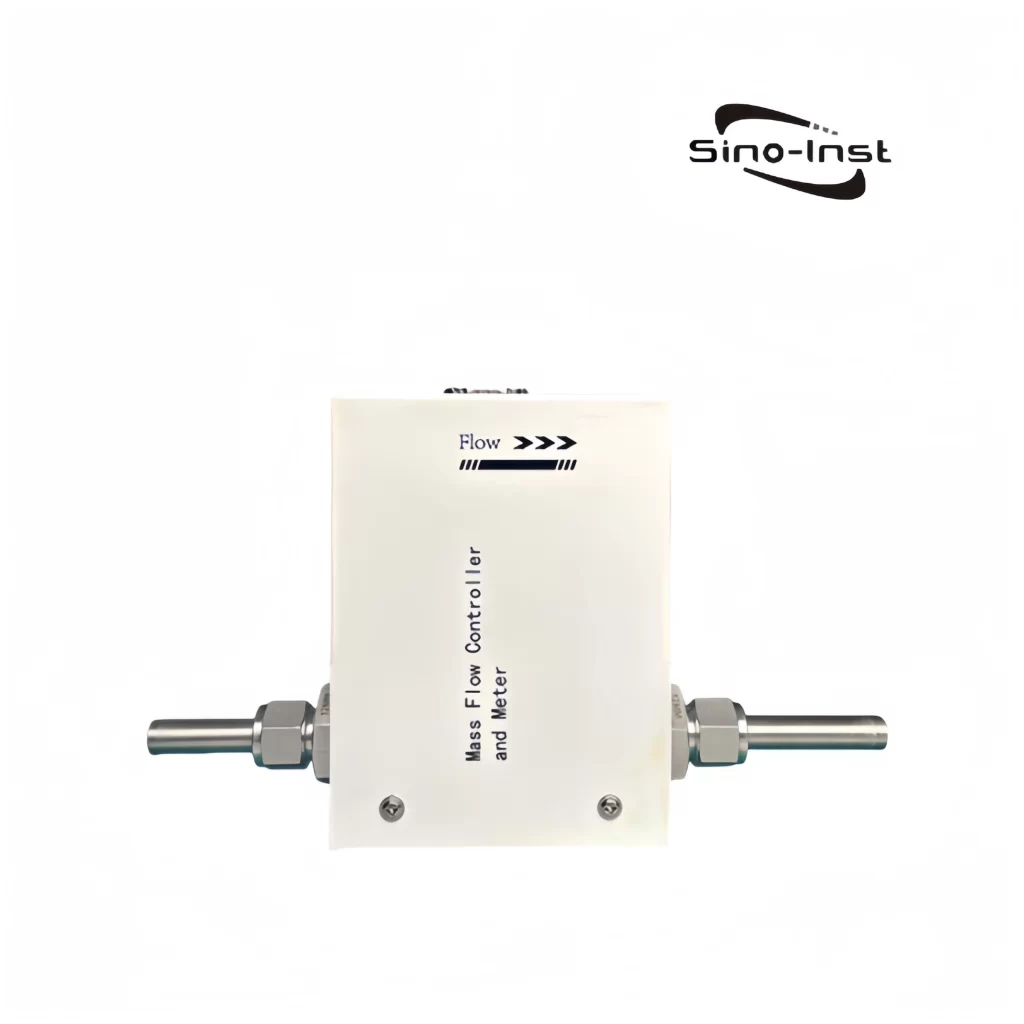

Sino-Inst supplies Coriolis, thermal, and differential pressure mass flow controllers/mass flow meters. Suitable for various gases and liquids, with flow ranges covering small sizes of 2 SCCM and 10 g/h, as well as large ranges of 7000 SCCM and 1000 kg/h.

Featured Mass Flow Controllers MFM/MFC

Data Sheet

FAQ

Sino-Inst provides complete customized liquid/gas metering systems for users in various industries, enabling precise control of fluid additive dispensing. Applications include chemical, food, and pharmaceutical industries.

We also support customized mass flow controllers for high temperature, low temperature, and high pressure applications. Please feel free to contact our sales engineers!

-1.jpg)