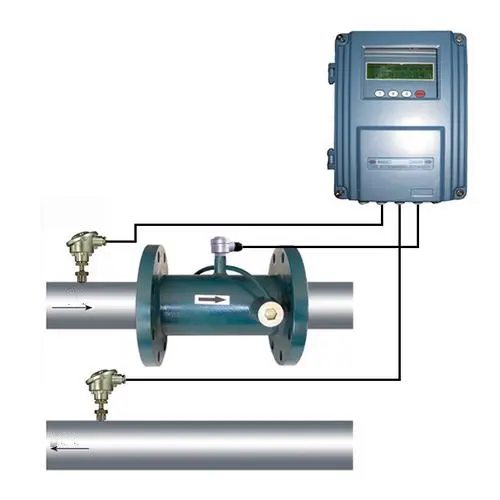

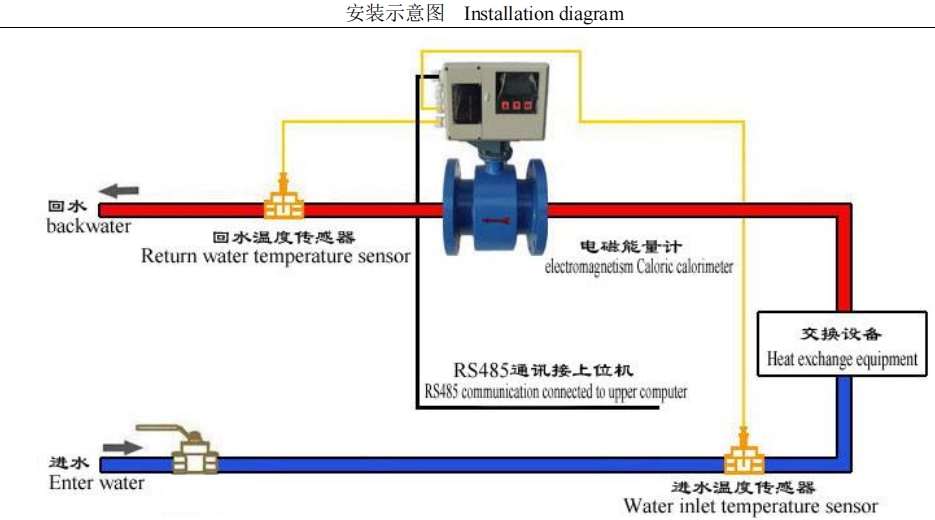

Electromagnetic heat meter is an inductive instrument for measuring conductive media, suitable for measuring the volume flow of conductive liquids with a conductivity greater than 5μs/cm. The electromagnetic heat meter consists of a flow measurement unit, a heat calculation unit and a paired temperature sensor (PT1000), which can calculate, accumulate, store and display the amount of heat absorbed or released in the heat exchange circuit. The same electromagnetic heat meter can measure heat loss and cold loss respectively.

Case Sharing

A customer from Bulgaria saw our electromagnetic heat meter product on our website and provided us with his actual measurement parameters. Finally, we determined the parameters of the electromagnetic heat meter together.

- Electromagnetic heat meter

- DN50mm

- 316L electrode

- PTFE lining

- AC220V

- Output 4~20mA, with RS485 communication

- LCD displays instantaneous flow and cumulative total

- Integrated flange connection

- Flow range: 3.5~35m³/h

- Accuracy: 0.5%

- Temperature resistance: 80℃

- Pressure resistance: 1.6MPa

- Equipped with two Pt1000 temperature sensors

Working Principle

In the air conditioning or heating system, the heat exchange circuit progresses, the outlet pipe is connected to one Pt1000 electric wire temperature sensor, and the temperature of the water pipe is precisely collected and the water pipe temperature signal is sent.

Current status, exit pipe installed flow rate sensor (tube electromagnetic flow meter), precision collection pipe flow rate signal.

Capacity calculator for input temperature, flow rate signal, communication K system law principle calculation, consumption capacity. This is the most effective number in the computer. Calculate the amount of heat, cooling amount, equal effectiveness flow rate, supply water temperature and temperature difference, etc. Communicate with the computer, actually intelligent management.

Application Of Electromagnetic Heat Meter

- Application In Central Heating System

In large central heating system, electromagnetic heat meter is the key equipment to achieve accurate heat measurement and fair charging. It is installed on the heating pipeline to accurately measure the heat delivered from the heat source to each user end. Based on these data, the heating company charges according to the actual heat used by the user, which changes the previous extensive mode of charging by area and effectively promotes the energy-saving awareness of users.

- Heat Monitoring In Industrial Production

In the industrial production process, many links involve the transfer and utilization of heat. Electromagnetic heat meter can be used to monitor the heat output and recovery of industrial boilers, heat exchangers and other equipment. Not only that, for some waste heat recovery systems, electromagnetic heat meter can accurately measure the recovered heat, provide data basis for enterprises to evaluate the waste heat utilization effect, and help enterprises achieve energy conservation and emission reduction goals.

- Application And Development In Intelligent Buildings

With the rise of the concept of intelligent buildings, electromagnetic heat meter plays an important role in building energy management systems. It is integrated with the building automation system to realize real-time monitoring and analysis of heat usage in various areas of the building. Property management personnel can reasonably adjust the operating time and power of heating equipment based on these data to achieve intelligent heating control. At the same time, for newly built green buildings, the application of electromagnetic heat meters helps to meet the requirements of building energy-saving standards and improve the overall energy efficiency of buildings.

Product Features

More solutions for flow measurement

- Ultrasonic vs Magnetic Flow Meter: Analyze and Help You Choose

- Case: Flow Meter for Liquid Cement Additive

- Cryogenic Flow Meters Custom Cases

- Customer Case: Customized DN10 Flow Meter for Petrol

- Variable Area Flow Meter Case: Oxygen Flow Measurement

- Negative Pressure-Vacuum Flow Meters

- Annubar Flow Measurement: Principles, Applications, And Advantages

- Insertion Magnetic Flow Meter | Better Solution for Large Diameter Pipes

- Sewage Flow Meters and Effluent Flow Meters for Wastewater

- Gear Flow Meter Technologies: Oval, Spur, and Helical

- More Convenient Flow Measurement-Battery Operated Flow Meters

- Complete Guide for Micro Motion Flow Meters

- Guide For Syrup Flow Meters

- Everything You Need To Know About Propane Gas Flow Meters

- Opt The Right Flow Meter For Soy Sauce Flow Measurement

- Dirty Water Flow Meters

- Potable Water Flow Meters In Domestic Water Supply Systems

- The Right Saltwater And Seawater Flow Meter For Your Needs

- Guide for Raw Water And Fresh Water Flow Meters

- Electromagnetic Interference Resistant Flow Meters

- Helical Flow Meters: Accurate Flow Measurement For Challenging Applications

Summary

Sino-Inst’s electromagnetic heat meter is popular all over the world, supporting body, electrode, lining, pressure and temperature customization on demand. You tell us the working conditions, we give a dedicated solution, so that each one is just right for you. If you have any needs, please feel free to contact us.

-1.jpg)