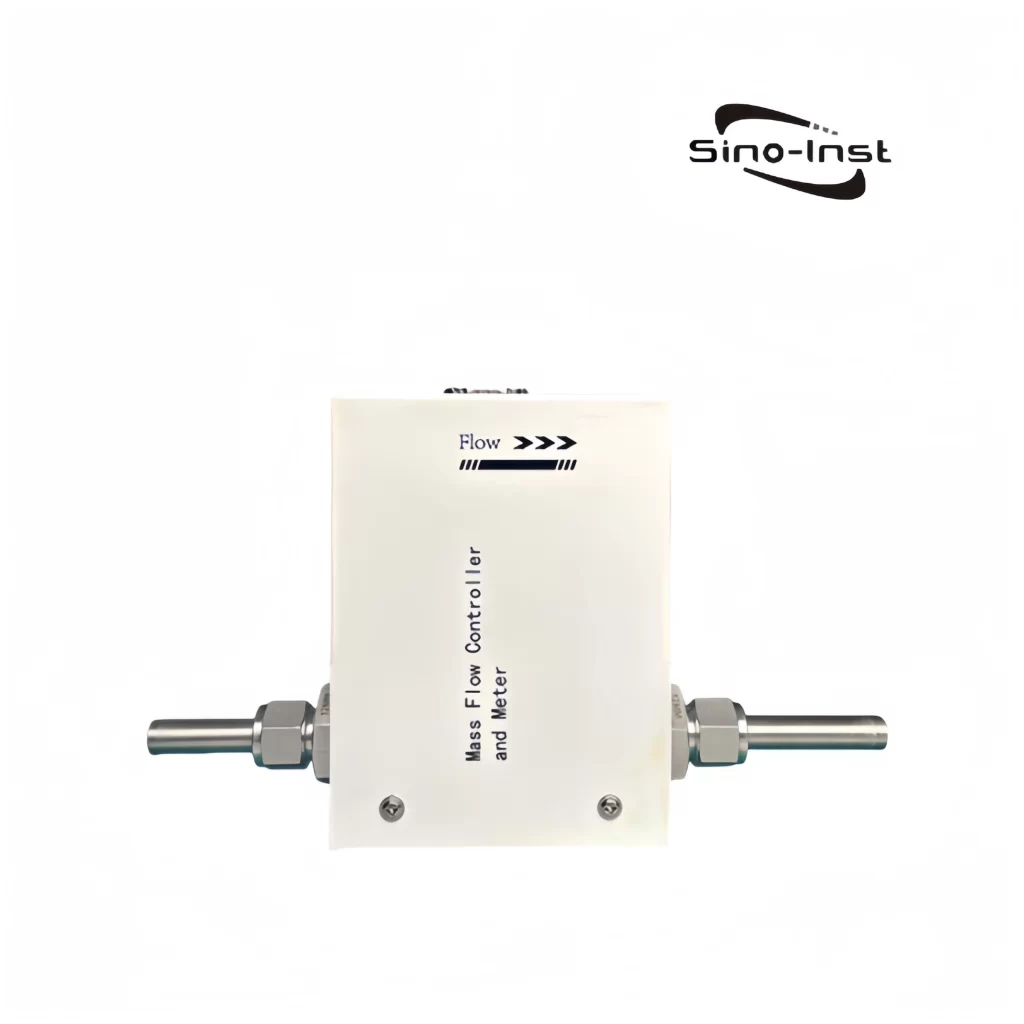

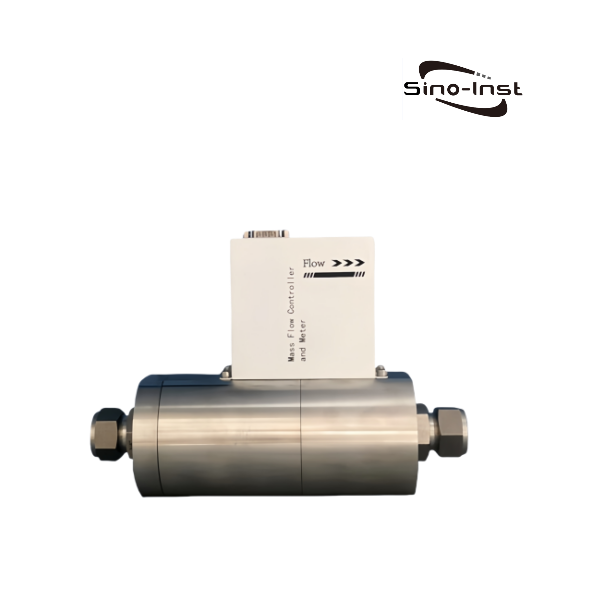

AC-S030 Micro-range Mass Flow Controller/Flowmeter is a small-range product of analog signal. Its range can be from 10SCCM to 100SLM, suitable for nearly 100 gases such as hydrogen, nitrogen, oxygen, carbon monoxide, carbon dioxide, rare gases, etc. This product adopts new technology, +24VDC power supply, and the maximum pressure resistance can reach 10Mpa.

Features

- Fast response speed

- High-pressure resistance

- Strong anti-interference

- Long data transmission

- Accurate flow control

AC-S030 Micro-range Mass Flow Controller/Flowmeter Technical Parameters

| Product model: | AC-S030C / AC-S030M |

| Flow range (N2): | 10SCCM—30SLM, 20SCCM—100SLM |

| Control range: | 2%-100%/1%-100% |

| Accuracy: | ≤±1.0%F.S |

| Linearity: | ≤±0.5%F.S |

| Repeatability: | ≤±0.2%F.S |

| Valve type: | Normal closed valve |

| Response time: | ≤2sec |

| Maximum pressure resistance: | 50Bar, 100Bar |

| Communication signal: | 0-5V/4-20mA analog communication |

| Power supply method: | 24V DC |

| Leakage rate: | 1X 10-9atm.cc/sec He |

| Connector size: | 3mm, 6mm,10mm, 1/4,3/8, etc. |

Note:

- Thermal gas mass flow controllers and thermal gas mass flow meters are usually calibrated with ammonia (N2) before leaving the factory.

- Mass flow unit: SCCM (standard milliliters per minute), SLM (standard liters per minute)

- Standard conditions:

Temperature -293.15K (20°C)

Pressure -101325Pa (760mmHg)

F.S (Full Scale) means full scale

Mass flow controller working principle

Thermal MFC uses the principle of heat transfer to measure gas flow. It contains two temperature sensors, one for measuring the upstream temperature of the gas and the other for measuring the downstream temperature of the gas after passing through the heating element. Changes in gas flow will affect the heat transfer, thereby changing the temperature difference between the two sensors.

By adjusting the power of the heater to maintain a constant temperature difference, the controller can accurately regulate and control the flow of the gas. Thermal MFC has the characteristics of high precision and fast response speed, and is suitable for occasions that require fast response and precise control.

What is the range of a mass flow controller?

Range: The minimum to maximum flow rate that a mass flow meter/mass flow controller can measure.

Range ratio: The ratio of the maximum flow rate and the minimum flow rate that a mass flow meter/mass flow controller can measure and control. For example, the standard range ratio of a mass flow controller is 100:1, and a wider range ratio can also be customized.

Thermal gas mass flow controllers and flow meters detect and control gas flow within a certain range. If it is lower than or exceeds the fixed range of the range, we generally judge this data as having no reference significance.

Micro-range Mass Flow Controller/Flowmeter Use in the Biotechnology Industry

In order to ensure and control the growth rate of microorganisms, the rated gas must be accurately and repeatedly added to the bioreactor. Therefore, the accuracy and repeatability requirements of the thermal gas mass flow controller are higher.

Sino-Inst’s AC and DC series of thermal gas mass flow controllers are combined with fermentation engineering biochemical reactions. They are widely used in the pharmaceutical industry, food industry, energy industry, chemical industry, agriculture, plant gene modification, biological nitrogen fixation, engineering insecticides and biological pesticides, microbial nutrients, environmental protection, etc.

Micro gas mass flow controllers can accurately and repeatedly add a specified amount of gas (such as nitrogen, oxygen carbon dioxide gas, etc.) to the bioreactor. The fully automated connection and operation mode facilitates information exchange and monitoring between devices. Therefore, in the biotechnology industry, the use of thermal gas mass flow controllers is also very extensive.

According to the inconsistent sizes of reactors in the biotechnology industry, Sino-Inst’s thermal gas mass flow controllers can match various flow requirements. Small volumes such as: 10ml/min, 1500ml/min; medium and large flows such as 10l/min or 200l/min, etc.; the range of options and configurations is very wide.

More Gas flow measurement and control solutions

- Mass Flow Meter Vs Magnetic Flow Meter

- Liquid Mass Flow Meters And Its Significance

- Gas Mass Flow Meters: Applications, Benefits, And Top Manufacturers

- Types Of Mass Flow Meters And Different Measurement Techniques

- Bulk Flow Meter for Solids | Applications and Benefits

- A Comparative Analysis Of Vertical And Horizontal Flow Meters

- LPG Gas Flow Meters With Some Prominent Manufacturers And Suppliers

- Grease And Lube Flow Meters

Sino-Inst’s Micro-range Mass Flow Controllers/Flowmeters combine foreign advanced technology and adopt a new sensor manufacturing process. It has the advantages of fast response speed, high accuracy, stable flow control, wide pressure range, good linearity, etc. It is suitable for most dry and clean gases (and a few corrosive gases).

The AC and DC series of thermal gas mass flow meters and controllers with high-cost performance, economical and easy to use are widely used. They are exported to various countries such as the United States, the United Kingdom, Argentina, Canada, Indonesia, etc. Parameter customization is supported.

If you need to purchase a Micro-range Mass Flow Controller/Flowmeter or have related technical questions, please feel free to contact us!

AC-S030 Micro-range Mass Flow Controller/Flowmeter - Sino-Inst

AC-S030 Micro-range Mass Flow Controller/Flowmeter is a small-range product of analog signal. Its range can be from 10SCCM to 100SLM, suitable for nearly 100 gases such as hydrogen, nitrogen, oxygen, carbon monoxide, carbon dioxide, rare gases, etc. This product adopts new technology, +24VDC power supply, and the maximum pressure resistance can reach 10Mpa.

Product SKU: AC-S030 Micro-range Mass Flow Controller/Flowmeter

Product Brand: Sino-Inst

Product In-Stock: PreOrder

5

-1.jpg)