SI-100 digital flow switch is suitable for flow monitoring of different media, including some impure liquid and gas media. Digital display of the flow state of the medium. Designed based on the principle of heat transfer temperature difference.

SI-100 digital flow switch has many product advantages that have been fully utilized in industrial furnaces, welding equipment, laser equipment, microwave equipment, glass machinery, lubrication machinery, printing machinery, machine tools, and large transformers.

Features

SI-100 Digital Flow Switch Technical Specifications

Basic parameters

| Medium | Liquids, Gases | |

| Monitoring function | Alarm indication | LED(red) |

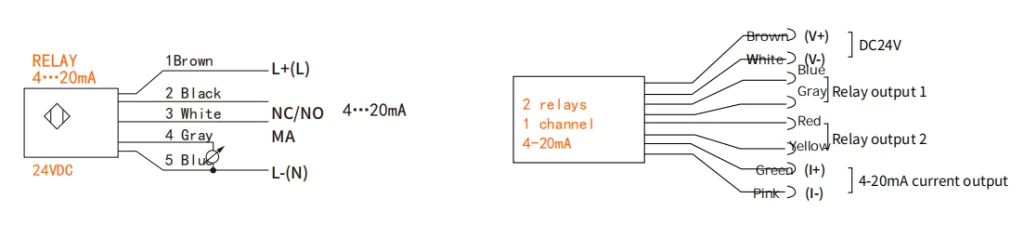

| Signal output | Realy, PNP, 4-20mA | |

| Maximum load | Relay < 1A; PNP < 150mA, Analog < 500Ω | |

| Temperature range | Medium | -20℃~+80℃ |

| Environment | -20℃~+80℃ | |

Electrical parameters

| Working voltage | DC 24 V(18…32 V) |

| No-load current | <80 mA |

| Status indication | 4-digit,7-segment LED indicator |

| Protection level | IP67 (when plugged in) |

| Connectors | M12 plug-in connection, 5-pole |

Flow monitoring

| Adjustment range | Water 1…150 cm/s |

| Oil 3…300 cm/s | |

| Gas 20…2000 cm/s | |

| Repeat accuracy | +2% |

| Initialization time | Approx 18s |

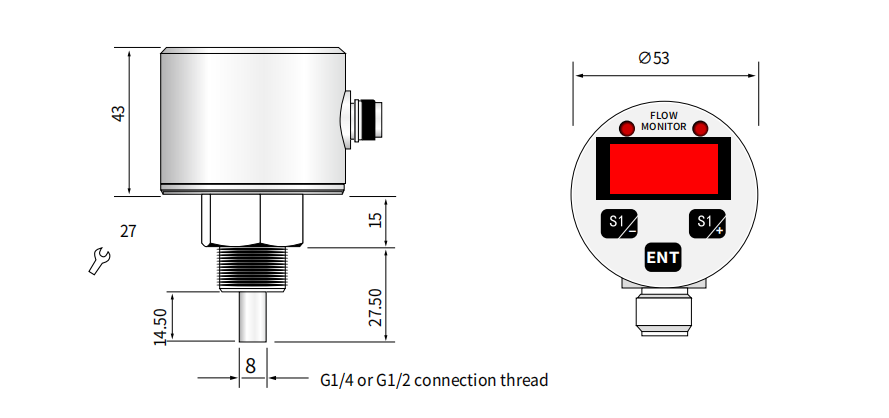

Mechanical parameters

| Material | Housing: Stainless steel |

| Probe: Stainless steel | |

| Weight | Approx 0.4kg |

Wiring Diagram

What is a flow switch used for?

Flow switches are used to monitor and control fluid flow in industrial process systems. Automated industrial systems that handle fluid media rely heavily on flow switches to ensure safe and optimal flow rates. Flow switches monitor a preset flow rate level and perform two functions when that flow rate level is reached: either close its contacts and turn on a specific device, or open its contacts and turn off a specific device.

What is the difference between a flow switch and a flow sensor?

Although both flow switches and flow sensors can be used to monitor the flow of media within a system, the difference between flow switches and flow sensors is that flow sensors can only monitor and display fluid flow information; flow switches monitor flow and output switching signals and trigger specific actions of machines within the system.

How does a flow switch work?

There are many different types of flow switches on the market with different functions, but what all flow switches have in common is that when the flow reaches the switch’s set value, it can open or close a circuit to trigger an action: whether it is turning a pump on or off, or triggering an alarm.

Flow switches are configured as normally open (NO) or normally closed (NC). This refers to the default state of the switch. If the NO switch is on, the circuit is open (OFF) until it is triggered in some other way. With an NC switch, the circuit is closed (ON) until it is triggered in some other way.

Digital Flow Switch works based on the principle of heat transfer and temperature difference. A heating module and a temperature sensing module are placed in a closed probe. The heat transfer temperature difference value of the probe is closely related to the flow rate of the measured medium. When the medium in the pipeline flows at a stable flow rate. The sensing module receives a fixed value sensed by the heating module. When the flow rate flowing through the probe changes, the thermal sensing module will transmit a temperature difference signal that changes accordingly, and the processor will output the corresponding flow rate result.

Sino-Inst supplies various types of flow switches, including thermal conductivity flow switches, digital flow switches, temperature flow integrated switches, mechanical flow switches, etc. You can contact our sales engineers at any time to select the right flow controller for you.

-1.jpg)