SI-210 Electronic Flow Switch / Sensor is a switch that instructs the system according to the flow rate. When the flow reaches the limit value, the flow switch sends a signal or alarm, and the system will run or stop. Electronic Flow Switch / Sensor monitors the flow of liquid in the pipeline in real time and provides switch output. And LED is used to display the flow rate of the fluid in real time.

Gas and liquid dual-purpose type. It can be used for flow interruption detection of pneumatic and hydraulic systems, circulating water, cutting fluid and lubricating oil, as well as idling protection of pumps.

Features

- No moving parts, maintenance-free, easy to install.

- One model is suitable for various pipe diameters.

- The switch quantity is continuously adjustable.

- Extremely low pressure loss,

- Compact structure, LED displays flow trend and switch status.

- Applicable to water, oil, gas and other media compatible with stainless steel.

SI-210 Electronic Flow Switch / Sensor Specifications

| Setting range | Water–1…200cm/s, Oil–3…300cm/s, Air–20…2000 cm/s (Specific factory calibration or on-site customization is required.) |

| Measurement medium | Water, oil, gas and other media compatible with stainless steel |

| Repeatability | 1%@<0.6m/s; 3%@<1.5m/s; 10%@>1.5m/s; |

| Switch output | (NO+NC) |

| Output type | PNP/NPN/Relay optional/NO/NC can be set |

| Load capacity | 500mA at 24Vdc (NPN and PNP type) 60W (relay type) |

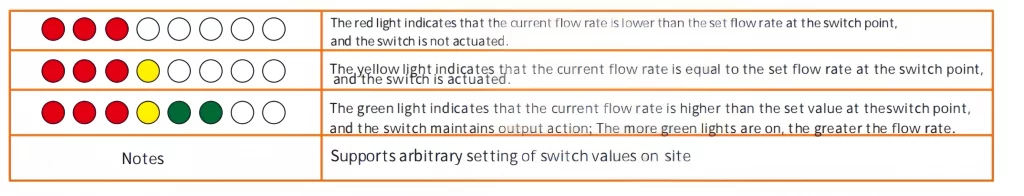

| Display design | 3 red LEDs (flow rate < switch point) 1 yellow LED (flow rate = switch point) 4 green LEDs (flow rate > switch point) |

| Flow indication | LED lights (8) |

| Setting method: | Button setting |

| Withstand voltage range: | 100bar (300bar optional) |

| Medium temperature change: | 4°C/s |

| Response time: | 1…13s, typical value 2s |

| Initialization time: | About 8s |

| Power supply: | 24±20%VDC |

| Electrical protection: | Reverse phase, short circuit, overload protection |

| Protection level: | IP67 |

| Medium temperature: | -20…85°C |

| Ambient temperature: | -40…85°C |

| Storage temperature: | -20…100°C |

| Wiring method: | M12 connector/directly attached 2m cable optional |

| Material: | Probe: 304 stainless steel; Housing: 304 stainless steel |

| Weight: | About 0.4kg |

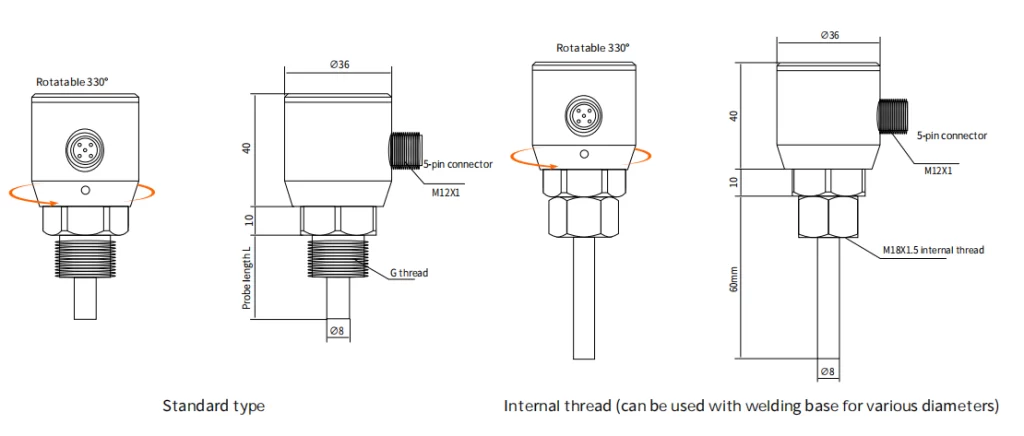

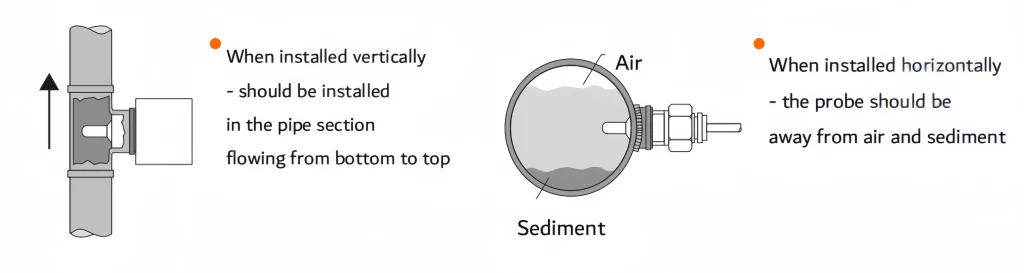

Electronic Flow Switch Installation Direction

Panel Setting Process

Calibration: Ensure that the medium in the pipeline is full, use the magnetic handheld setter to press and hold the “left-” key for more than 3S, the red light flashes, and the zero calibration is successful.

Sensitivity setting: Press and hold the “right +” key to enter the full light flashing state, and press the “right +” key once to increase/decrease the sensitivity, which can be cyclic.

What are flow switches used for?

A flow switch is a device used to control the flow of liquid or gas. It monitors the flow state of the fluid in the pipeline to achieve automatic control of the switch. It is widely used in industrial production, environmental water treatment, heating and ventilation, and other fields.

Flow switches can avoid failures caused by too much or too little fluid in the pipeline and improve the stability and safety of the process. In the field of environmental water treatment, flow switches can be used to monitor the flow of wastewater to ensure that wastewater is discharged in accordance with the prescribed standards and protect the environment. In the heating and ventilation system, the flow switch can regulate the speed of hot water flow to achieve heating or cooling effects.

How does a flow switch work?

The flow switch is mainly composed of a flow sensor and a switch control unit. When the detected fluid flows through the sensor, the sensor will send a signal. After the control unit makes a judgment, the control switch is turned on or off. Thus, the flow rate is automatically adjusted.

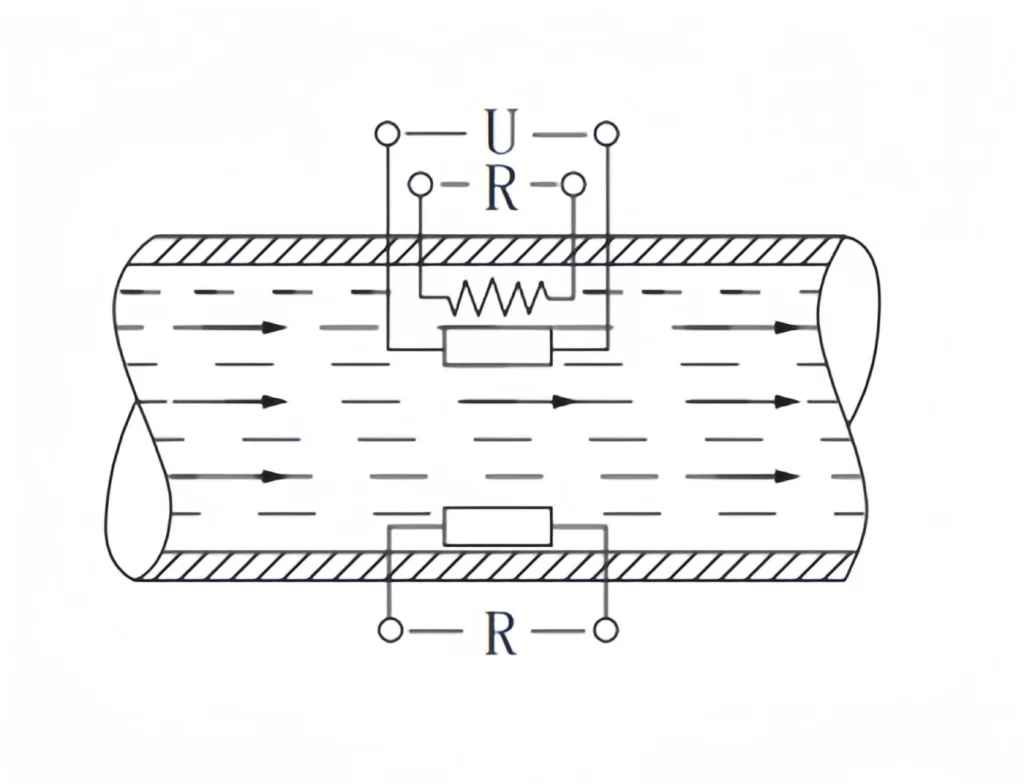

Our SI-210 series electronic flow switch is based on the thermal principle. Two resistors are contained in the closed probe. One of them is heated as a detection resistor, and the other is not heated as a reference resistor. When the medium flows, the heat on the heating resistor is taken away and the resistance value is changed. The difference between the two resistances is used as a basis for determining flow rate.

Sino-Inst’s electronic flow switch is suitable for a variety of media and working conditions, including liquids, gases and other fluids. Its corrosion resistance and high temperature resistance enable it to operate stably and for a long time in harsh industrial environments. In addition, the switch also supports a variety of output signal options, such as PNP, NPN, relay, etc., which is convenient for users to choose according to actual needs.

Sino-Inst is committed to providing high-quality products and services to every customer and jointly promoting the improvement of industrial automation. For more detailed information or customized solutions about thermal conductivity flow switches, please contact our professional team.

-1.jpg)